The rapid evolution of additive manufacturing is redefining the field of prosthetics, enabling new levels of customization, efficiency, and clinical precision. Unlike the traditional method of plaster casting and manual shaping, today’s digital workflows rely on 3D scanning, data-driven prosthetic design, and industrial 3D printing technology to deliver patient-specific solutions.

At the center of this transformation are industrial 3D printers capable of producing durable, lightweight 3D-printed prosthetics with consistent quality. In the manufacturing process, clinicians first capture an accurate digital model of the patient’s residual limb using non-contact scanning systems. This data forms the foundation for a fully digital printing process, ensuring that prosthetic sockets and other components are precisely adapted to fit each user.

Technologies such as Selective Laser Sintering (SLS) and Jet Fusion have become the most widely adopted methods for producing high-performance printed prosthetics. These powder-bed fusion technologies allow complex geometries, optimized wall thickness, and excellent mechanical properties—capabilities that are difficult or impossible to achieve with conventional fabrication.

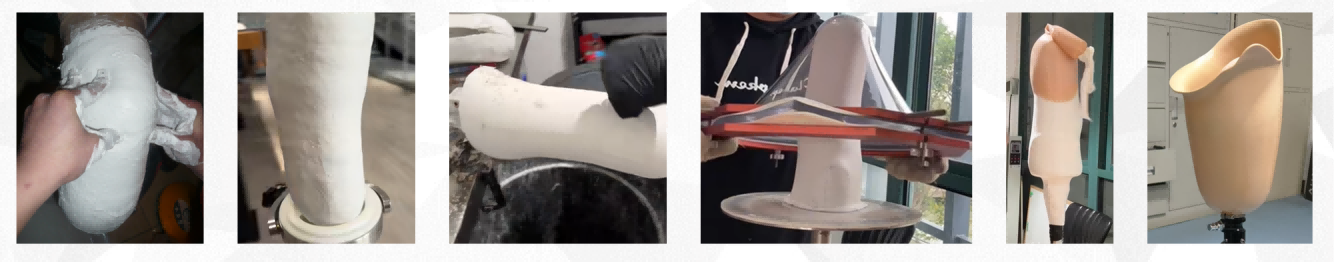

The Traditional Method: Skilled, Slow, and Experience-Driven

Prosthetic fabrication has long been a hands-on craft. Veteran prosthetists rely on plaster casting, manual shaping, and thermoplastic forming to create sockets—a manufacturing process that typically takes two to three days per iteration.

The traditional method begins with wrapping the patient’s residual limb in plaster bandages to create a negative mold. A positive plaster model is then cast, manually modified millimeter by millimeter to adjust pressure zones and load-bearing areas. As many practitioners note, a deviation of even one millimeter can affect gait and comfort.

While proven, this approach is labor-intensive, material-heavy, and highly dependent on individual expertise. Patients often need multiple clinic visits, making the process time-consuming and difficult to scale—especially when compared to 3D printing prosthetics.

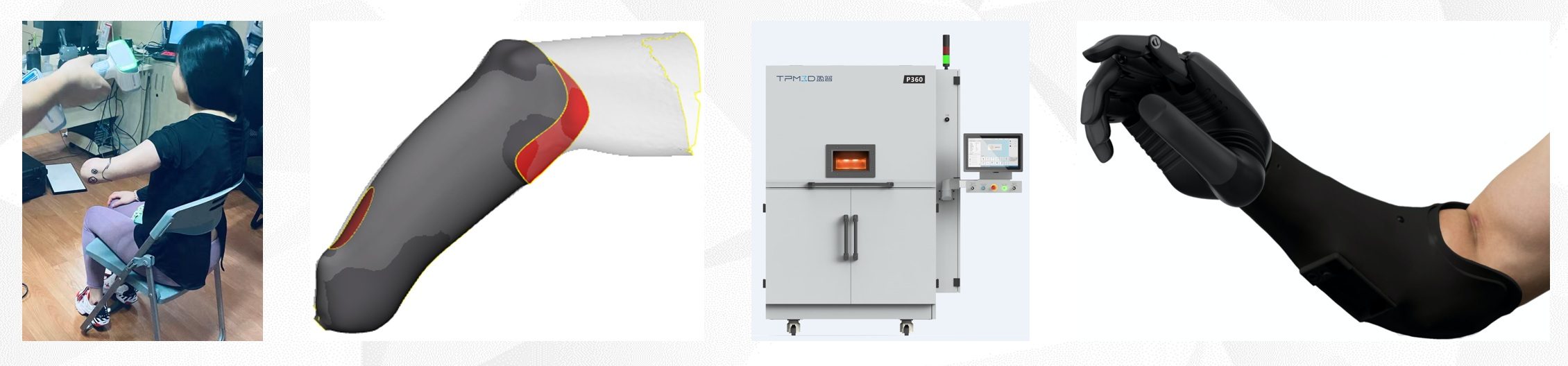

Digital Transformation: From 3D Scanning to 3D Printed Prosthetics

Today, 3D printing prosthetics is fundamentally changing this workflow. Modern prosthetic design now follows three core steps: 3D scanning, digital modeling, and 3D printers.

Using handheld 3D scanners, clinicians can capture high-resolution, sub-millimeter data of a patient’s residual limb in minutes—without physical contact. Compared to plaster casting, 3D scanning is cleaner, more comfortable, and capable of capturing anatomical details that were previously difficult to document.

The scan data is imported into specialized software, where clinicians digitally refine the prosthetic design—adjusting pressure points, optimizing geometry, and tailoring the socket to fit each user. This step can be completed in under an hour.

The final design is then sent to industrial 3D printers. Technologies such as SLS are widely used to produce printed prosthetics from high-performance polymer materials like nylon. The entire printing process can take just a few hours.

Measurable Benefits of 3D Printed Prosthetics

The benefits of 3D printed prosthetics are substantial. According to U.S.-based Quorum Prosthetics, digital workflows have reduced production time by up to 75% compared to traditional methods.

For patients, what once took weeks can now be completed in days, with clinic visits reduced from multiple fittings to just two. The elimination of plaster casting also improves comfort and hygiene, delivering a more patient-friendly experience.

From a performance standpoint, modern 3D-printed prosthetics rival traditionally manufactured products. SLS-printed nylon components offer excellent strength, fatigue resistance, and durability. For both inner and outer sockets, TPM3D Precimid1180 BLK Nylon 11 powder can be used, offering excellent toughness, impact resistance, wear and fatigue resistance.

The printed sockets are dimensionally accurate, ensuring a precise fit to the patient’s residual limb and providing reliable support to their body. After post-processing, the surfaces are smooth, waterproof, antibacterial, easy to clean, and highly durable—comparable to injection-molded products.

In terms of precision, 3D scanning provides sub-millimeter accuracy far beyond what can be achieved with manual plaster molding. Moreover, the digital model can be adjusted an unlimited number of times based on on-site measurements and dimensional data without the need for a new mold. This capability is particularly important in pediatric prosthetics, as growing children require new prosthetic sockets every few months.

Scaling Access Through Additive Manufacturing

Additive manufacturing also enables centralized production models. By consolidating demand into regional printing centers equipped with industrial 3D printers, providers can significantly reduce unit costs while maintaining consistent quality.

Perhaps most transformative is the potential for remote service delivery. Patients can undergo 3D scanning locally, while design and manufacturing are handled remotely—expanding access to high-quality 3D-printed prosthetic hands and other devices worldwide.

Global Adoption Across the Field of Prosthetics

Around the world, 3D-printed prosthetics are already improving lives. In the United States, MMA athlete Rustin Hughes replaced a heavy, uncomfortable traditional prosthesis with a digitally manufactured solution that fits precisely and can be adjusted in seconds.

In Europe, companies such as Bulgaria-based ProsFit use cloud-based platforms to allow clinicians to design and order custom 3D printed prosthetics remotely. In India, government-led initiatives have deployed 3D printing technology to deliver customized 3D-printed prosthetic limbs with dramatically improved comfort and mobility.

Clinicians and researchers worldwide are embracing digital tools at an accelerating pace, while universities explore next-generation solutions that integrate AI, robotics, and advanced prosthetic design.

From Craftsmanship to Data-Driven Precision

The shift toward 3D printing prosthetics marks more than a technological upgrade—it represents a structural transformation of the manufacturing process. Compared to traditional methods, digital prosthetics move the industry from experience-based craftsmanship to data-driven precision.

As 3D printers and additive manufacturing continue to mature, 3D printed prosthetic limbs—from sockets to advanced systems like a 3D-printed prosthetic hand—are becoming faster to produce, easier to personalize, and more accessible than ever before.

For millions of users worldwide, this evolution means one thing: prosthetic devices that truly fit each user—not just the body, but the life they are meant to support.

FAQ: 3D Printed Prosthetic Limbs

Q1: What are the main advantages of 3D printed prosthetics?

A1: 3D printed prosthetic limbs offer faster production, higher customization, better precision, improved comfort, and lower costs compared to traditional methods. The digital workflow allows repeated adjustments without new molds.

Q2: What materials are commonly used for 3D printing prosthetics?

A2: High-performance polymers such as nylon are widely used, especially in SLS and Jet Fusion printing, offering durability, flexibility, and a smooth, clean finish.

Q3: How does 3D scanning improve prosthetic fit?

A3: 3D scanning captures sub-millimeter details of the residual limb, enabling precise prosthetic design and a custom socket that fits each user comfortably.

Q4: Are 3D-printed prosthetics suitable for children?

A4: Yes. Digital models can be adjusted as children grow, allowing new printed prosthetics to be created quickly without repeated plaster casts.

Q5: Can 3D-printed prosthetics be made remotely?

A5: Absolutely. Patients can be scanned locally, and their 3D-printed prosthetic hands or limbs can be designed and manufactured remotely, making advanced prosthetics accessible worldwide.

Q6: Are 3D printed prosthetic limbs strong enough for daily use?

A6: Yes. Industrial-grade 3D printed prosthetic limbs, especially sockets made from PA11 or PA12 nylon, can achieve mechanical strength and durability comparable to traditionally manufactured prosthetics. With proper post-processing, they are suitable for long-term daily use.