TPM3D announced the launch of its new CF200+PPS200 compact professional SLS 3D printing system today at the Technology Stage during Formnext 2025. Developed to meet the growing need for compact, automated, and workspace-friendly SLS solutions, the system drew interest from professionals across multiple industries during its first public demonstration.

Small Footprint, Strong Capability

Built on TPM3D’s more than 20 years of SLS technology experience, the CF200+PPS200 provides an automated workflow for powder-based additive manufacturing. The system is composed of the CF200 SLS printer and the PPS200 powder processing station, covering the complete sequence of printing, depowdering, sieving, mixing, and powder supply.

The workflow is designed so that users do not need direct contact with powder materials, and the process can be initiated with a simple operation. With a printer footprint of 0.48 m² and total system space under 1 m², the solution is suitable for offices and R&D environments. It operates on a standard 220V power supply, reducing the need for special facility modifications.

Clean Design, Cleaner Workspace

The CF200 includes an integrated fresh-air filtration and odor-control system that helps reduce emissions produced during printing. The PPS200 applies negative-pressure depowdering and enclosed powder transfer to limit dust exposure.

This design enables installation in different working environments such as studios, laboratories, and small production spaces, where conventional industrial SLS systems may not be feasible due to environmental constraints.

Fast Prints, Faster Turnaround

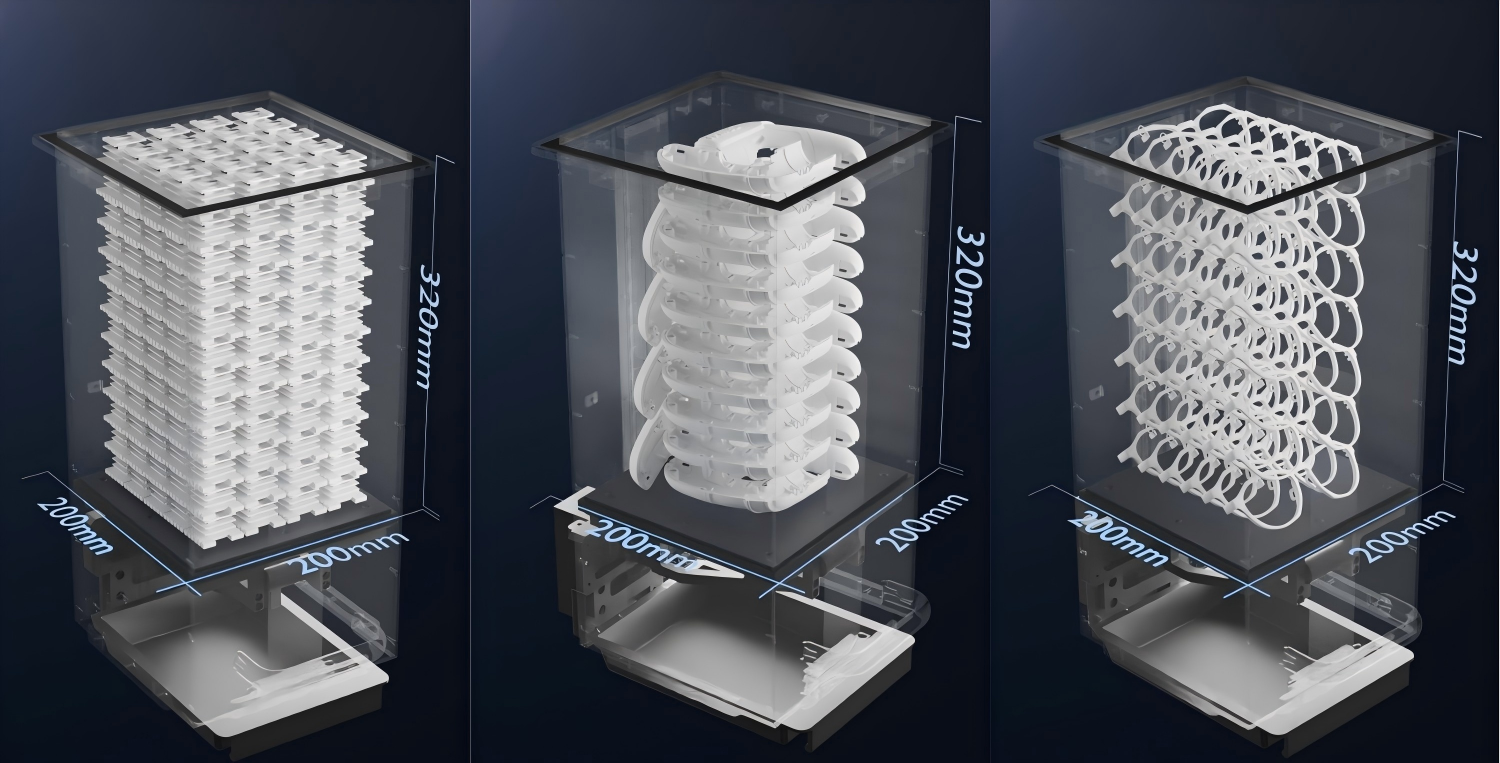

The system offers a 200 × 200 × 320 mm build chamber, supporting a range of prototyping and production applications. Example batch outputs include:

-

Up to 240 coil bobbins

-

Up to 12 power tool housings

-

Up to 42 eyewear frames

With a typical build rate of 0.5–0.8 L/h, the system supports short turnaround times, enabling many parts to be completed within 24 hours, depending on geometry and packing. It is compatible with PA11, PA12, TPU, and other engineering-grade powders, supporting requirements for dimensional accuracy and mechanical strength.

Safety Watched, Safety Assured

To support consistent operation, the CF200+PPS200 includes infrared sensors, powder-level monitoring, temperature supervision, and an onboard camera. The system meets CE certification requirements, aligning with widely used international safety standards.

One Platform, Many Possibilities

In an interview with 3D Natives earlier this year, TPM3D CEO Lucy Zhai observed that SLS technology is being adopted by a wider range of users, including SMEs, research institutions, and independent design studios. She noted that compact, user-friendly SLS systems are likely to play an increasing role in this development.

The CF200+PPS200 reflects this trend by combining compact dimensions, automated processes, and industrial-grade performance in a format suited to smaller workspaces.

TPM3D expects the system to support applications in consumer electronics, medical device development, education, cultural product design, small-batch manufacturing, etc. The company plans to continue expanding its line of additive manufacturing solutions based on ongoing user needs and market developments.

The CF200+PPS200 will remain on display at Formnext 2025, Hall 11.0, Booth C18, where live demonstrations and technical discussions are available throughout the exhibition.