TPM3D, a provider of industrial SLS (Selective Laser Sintering) 3D printing solutions, is set to unveil its latest innovation at Formnext 2025, taking place from November 18–21 at Messe Frankfurt. At Booth 11.0-C18, TPM3D will present its new compact professional SLS 3D printer, along with upgraded powder processing systems and advanced polymer materials, offering a more efficient, cleaner, and user-friendly additive manufacturing experience for global customers.

Global Launch: Compact Series Expands Industrial SLS Accessibility

Making its world debut, TPM3D’s new Compact Series marks the company’s latest step in bringing industrial-grade SLS performance to smaller-scale production environments. The lineup includes the CF200 SLS 3D printer and the PPS200 powder processing system, both designed to address common pain points in research, prototyping, and small-batch manufacturing—where large-format industrial SLS systems are often space- and resource-intensive.

With a footprint of less than one square meter, the CF200 and PPS200 are ideal for labs, small workshops, and office environments. They operate on standard 220V power and feature an intuitive user interface for easy operation. The CF200 is equipped with a 30W fiber laser and a 200 × 200 × 320 mm build chamber, compatible with PA11, PA12, and TPU materials.

The paired PPS200 powder processing unit enhances operational safety and cleanliness through a sealed powder transfer box and negative-pressure system that minimizes dust exposure. It automates part cleaning, powder recovery, blending, and refilling, creating a closed-loop workflow that simplifies SLS production from start to finish.

Enhanced Ecosystem: New Industrial Post-Processing and Materials

In addition to the Compact Series, TPM3D will showcase multiple industrial-grade upgrades that further strengthen its complete SLS ecosystem:

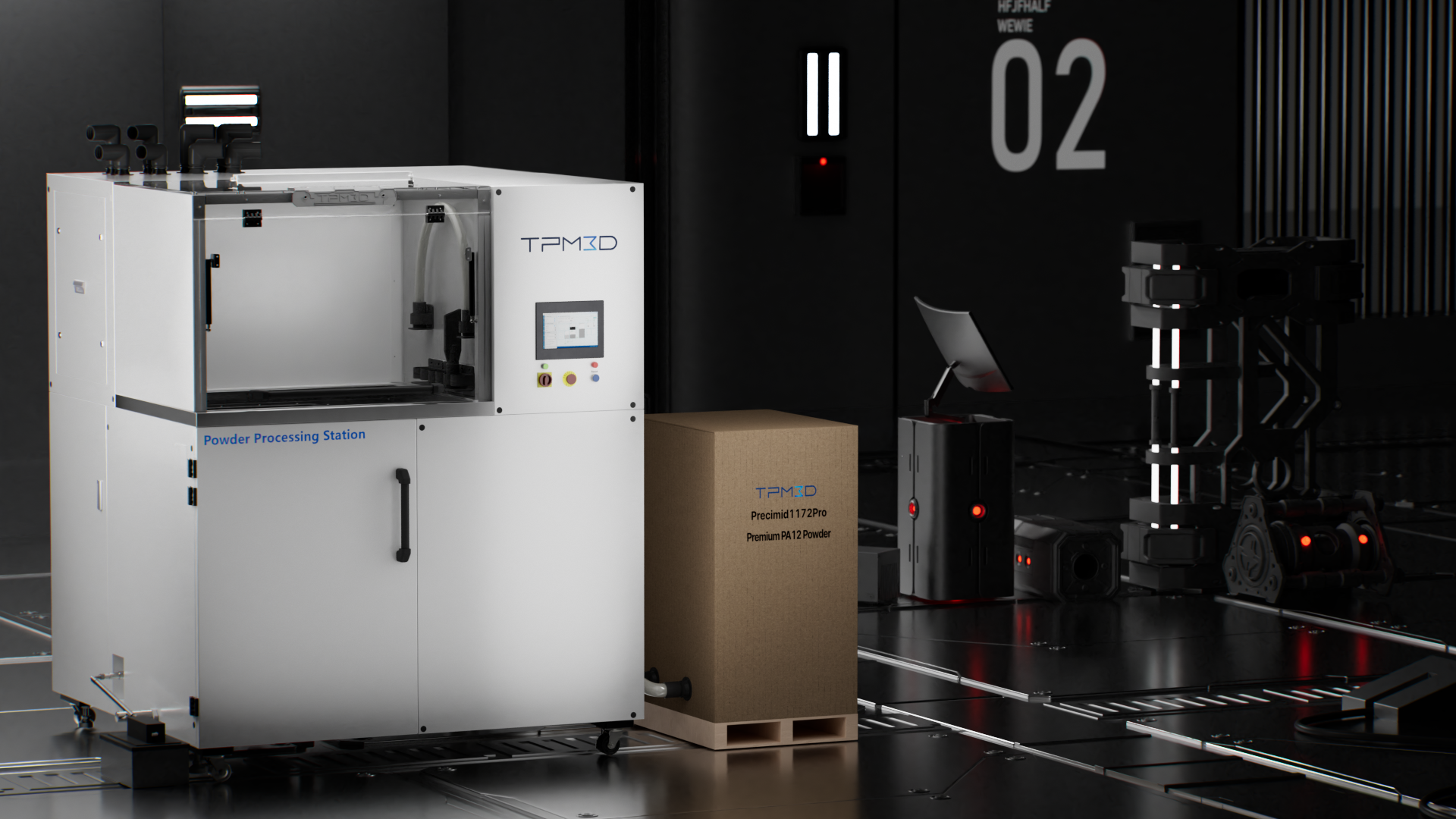

PPS V3.0: Next-Generation Powder Processing Station

The upgraded PPS V3.0 is the latest evolution of TPM3D’s acclaimed six-in-one powder management system. Compared with its predecessor, PPS V3 delivers a 20% smaller footprint, 90% lower compressed air consumption, and 50% higher cleaning efficiency. It now supports dual-printer operation, seamlessly connecting to TPM3D’s large-format models such as the P550DL and S600DL for fully automated, continuous production—reducing labor and maximizing productivity.

Two High-Performance Polymer Materials

TPM3D will also introduce two new SLS materials:

-

Precimid 1190, a high-toughness copolymer nylon, and

-

Precimid 1174Pro CF, a carbon-fiber-reinforced PA12 featuring excellent heat resistance and rigidity.

These materials expand the possibilities of SLS printing across demanding industrial applications.

Multi-Industry Applications and Art Collaborations

At Formnext 2025, TPM3D will display a diverse range of application achievements. In industrial and medical fields, the company will showcase examples such as precision mechanical parts and custom orthopedic supports. In consumer applications, visitors can expect to see 3D printed keyboards, laptop shells, footwear, and eyewear frames—illustrating the fine detail, surface quality, and reliability of TPM3D’s SLS systems.

TPM3D will also unveil two collaborative art installations—Utopia and Ocean of Silk—created with students and faculty from the Tsinghua University Academy of Arts & Design. These large, intricately structured works exemplify how SLS technology can merge artistic creativity with industrial-grade strength and stability.

Invitation to Explore the Future of Additive Manufacturing

As a pioneer in industrial SLS 3D printing, TPM3D continues to drive innovation across systems, materials, and process integration. Its participation in Formnext 2025 underscores the company’s commitment to making high-performance additive manufacturing more accessible and adaptable to a broader range of production scenarios.

TPM3D warmly invites industry professionals, partners, and visitors to join the team at Hall 11.0, Booth C18 during Formnext 2025 to experience the new Compact Series and explore the next generation of efficient, sustainable SLS manufacturing.