TPM3D has been sponsoring Formula Student China racing teams for several years, providing professional SLS 3D printing solutions to help students innovate and optimize their vehicles. In this article, we focus on Combustion Racing Cars and how TPM3D’s technology contributed to the 2021 season.

Tongji University Racing Team: Leading the Way

Founded in 2007, the Tongji University Racing Team (TJU Racing Team) is one of China’s top university formula racing teams. With two national championships and recognition as the top Chinese team in global university formula racing rankings, TJU Racing has established itself as a leader in innovation and performance.

For the 2021 season, TPM3D sponsored TJU Racing by supplying SLS 3D printed parts for the new car, TR21. In total, 62 components across the power assembly, chassis, and aerodynamic kit were produced, helping optimize the car’s power system, enhance aerodynamic performance, and reduce overall weight.

Aerodynamic Performance: Front and Rear Wing Ribs

The ribs of the front and tail wings of the TR21 were printed using TPM3D Precimid1180 BLK material, a polymer with ultra-high toughness and impact strength. These ribs support the new aerodynamic package, which can generate 1075 N of downforce at 20 m/s.

The improved aerodynamic package enhances the external flow field and aerodynamic sensitivity of the vehicle, significantly improving cornering speed and overall track performance.

Fuel Supply System: Strength and Precision

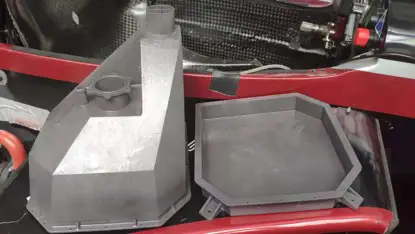

Key components of the fuel supply system—including the fuel tank, fuel suction pipe, and liquid baffle—were printed using TPM3D Precimid1172Pro GF30 BLK material. This glass-reinforced nylon provides excellent impact resistance and heat tolerance.

After assembly, the fuel tank meets the requirement for maintaining a pressure of 0.3 bar, while the liquid baffle effectively prevents fuel sloshing and separates bubbles in the fuel. This ensures both operational safety and stability during racing conditions.

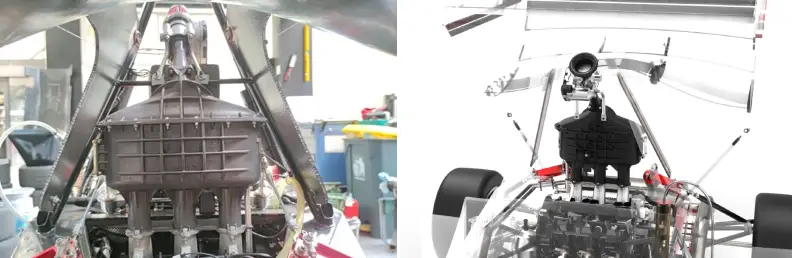

Air Intake System: Lightweight and Durable

The pressure stabilizing chamber and intake manifold of the racing engine were also 3D printed with Precimid1172Pro GF30 BLK material. These components are lightweight and capable of withstanding airflow impact.

Sealed with a plane sealant similar to silicone, the intake system maintains a negative pressure of 30 kPa and allows for disassembly without damaging the parts. This design further enhances the power assembly efficiency and reliability of the TR21.

Conclusion: Advancing Racing Innovation

Through the application of SLS 3D printing technology, TPM3D has helped TJU Racing optimize performance, improve safety, and reduce weight across critical systems of the TR21 combustion racing car. By providing lightweight, high-strength components for aerodynamics, fuel supply, and the intake system, TPM3D demonstrates the transformative potential of additive manufacturing in university-level motorsports.