Sculpture has always been a three-dimensional art form where materials are shaped into expressive works of creativity. Traditionally, sculptors relied on manual craftsmanship and conventional tools.

Today, however, 3D printing introduces a new digital language of creation, enabling artists to transform bold ideas into tangible works with unprecedented efficiency.

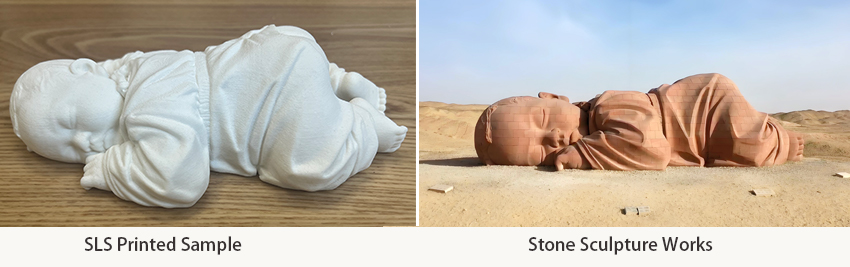

Among 3D printing technologies, Selective Laser Sintering (SLS) stands out for its ability to produce durable, high-strength parts without the need for support structures.

This “what you see is what you get” approach allows sculptors to explore intricate forms and experimental concepts, broadening artistic boundaries while accelerating the journey from design to reality.

Collaboration with Tsinghua University

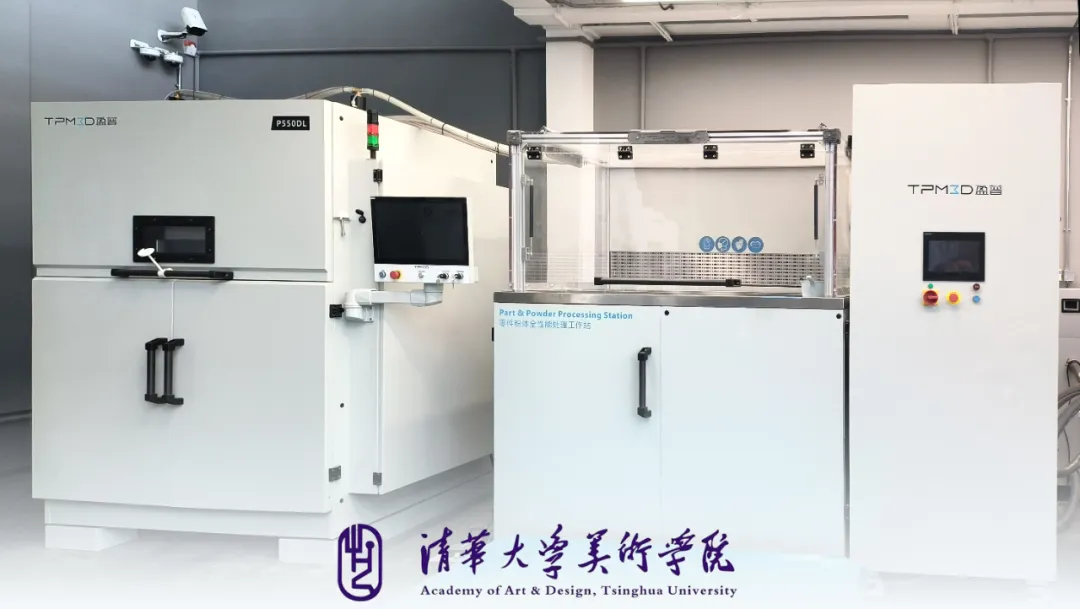

Recently, the Sculpture Department of Tsinghua University adopted TPM3D’s P550DL industrial-grade dual-laser SLS 3D printing system. The system will serve as a vital platform for design experimentation, teaching innovation, and practical sculpture applications, providing robust technical support for faculty and students alike.

This collaboration reflects Tsinghua University’s recognition of TPM3D’s research and development capabilities, product reliability, and comprehensive service system. With its large build volume, high printing efficiency, and exceptional stability, the P550DL is poised to help produce high-quality works of art, enriching academic research and contributing to the advancement of modern sculpture education.

About the Tsinghua Sculpture Department

Founded in 1999 and rooted in the Central Academy of Arts and Design, the Sculpture Department of Tsinghua University has grown into a leading base for modern sculpture education and research in China. With a strong faculty, distinctive academic features, and global influence, the department nurtures versatile artistic talent with international competitiveness.

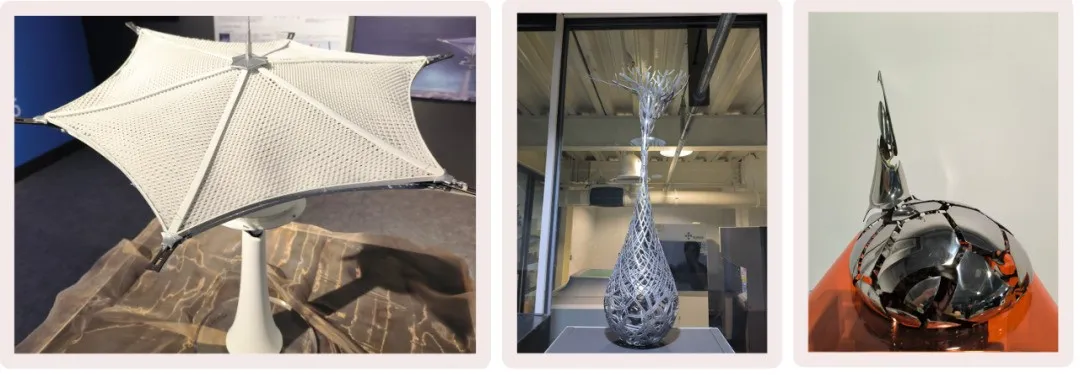

Tsinghua Art Academy Works Showcase

Its teaching and research span five major directions: figurative sculpture, abstract sculpture, experimental art, public art, and integrated approaches, combining tradition with innovation. Over two decades, it has become a hub for cultivating future leaders in sculpture and contemporary art practice.

About TPM3D P550DL

The TPM3D P550DL is a large-format, dual-laser SLS 3D printing system designed for industrial-scale applications. Widely used in automotive, education, prototyping, and healthcare, it delivers efficiency, cost-effectiveness, and scalability.

Key Features:

-

Large Build Volume: 550 × 550 × 850 mm, supporting single-piece large sculptures or batch production of smaller parts.

-

Dual-Laser System: Two 140W CO₂ lasers with dynamic focusing scanners, achieving a maximum scanning speed of 2 × 22 m/s for enhanced productivity.

-

Active Cooling Technology: Speeds up cooling, extends powder lifespan, and supports infinite powder recycling.

-

Built-in Nitrogen Generator: Reduces costs by eliminating the need for external gas supplies.

Efficient Production with PPS

For large-scale printing, post-processing can often be challenging. To address this, TPM3D provides the Part & Powder Processing Station (PPS). This integrated solution combines six functions—part cleaning, powder recycling, powder intake, powder mixing, powder feeding, and dust collection—into one system.

By streamlining these processes, the PPS significantly improves efficiency, lowers labor costs, and ensures safe, production-grade performance for multi-laser systems like the P550DL.

Customer Feedback

The adoption of TPM3D’s technology at Tsinghua University has been met with positive feedback. Professor Kong Fandi from the Sculpture Department commented:

“We are impressed with the P550DL’s dual-laser printing speed and large-format capabilities. The PPS makes part cleaning, powder recycling, and automatic powder supply much easier, enabling independent operation. The installation and training were thorough, and the after-sales service team demonstrated great professionalism and dedication.”

Expanding Artistic Boundaries

By integrating cutting-edge SLS 3D printing technology with artistic exploration, this partnership between TPM3D and Tsinghua University represents an exciting step forward. The P550DL not only empowers sculptors to reimagine the possibilities of form and material but also reinforces the role of technology in shaping the future of contemporary art.