Introduction: The Paradigm Shift to Polymer Powder Additive Manufacturing

Selective Laser Sintering (SLS) has fundamentally transformed its role within the manufacturing landscape over the last decade. Historically recognized primarily as a tool for rapid prototyping, SLS technology has successfully matured into the most widely utilized form of additive manufacturing (AM) for the production of end products.

This pivot reflects a significant technological maturity, addressing the escalating industrial demands for volume, versatility, and material performance.

The Ascendancy of Selective Laser Sintering (SLS) in Production

The market trajectory clearly reflects the shifting priorities of industrial users. For the first time in 2021, the global market size of polymer powder 3D printing surpassed that of photopolymer 3D printing, confirming the establishment of SLS as the dominant, mature technology for manufacturing high-demand, functional parts.

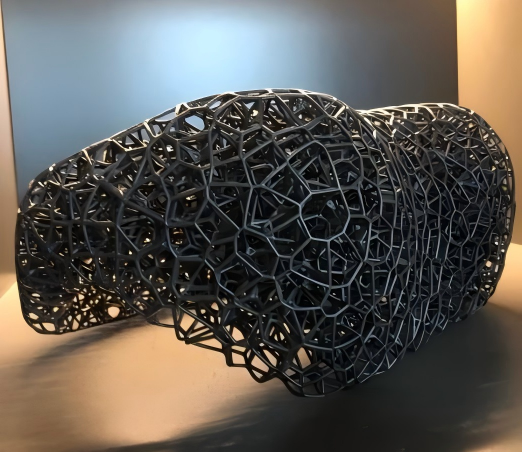

SLS facilitates rapid, versatile, intricate, and cost-effective production across diverse applications because it eliminates the need for support structures. This support-free operational principle distinguishes it from technologies like Fused Deposition Modeling (FDM) or stereolithography, allowing for the immediate realization of complex internal features, lattices, and hollowed designs.

The industrial focus is no longer on simply making a part, but on manufacturing it efficiently, reliably, and in compliance with stringent quality standards.

TPM3D: Two Decades of SLS Innovation

TPM3D enters this competitive industrial arena with a deep foundation built upon technological expertise spanning more than 20 years.

The company’s history traces back to 1999 when its scientific research team was established, positioning it as one of China’s pioneering players in SLS 3D printing services. This extensive history translated into groundbreaking regional achievements, notably the launch of Asia’s first self-developed SLS 3D printing system in 2007.

The company’s trajectory highlights a strategic commitment to global engagement and technological refinement.

A joint venture formed with Stratasys in 2014 provided critical investment and accelerated global outreach, further solidifying the technology and refining the industrial systems portfolio.

Following this period of joint development, TPM3D successfully spun off from Stratasys in 2019, rebranding and operating independently. This history demonstrates not only technological stability but also the business acumen required to adapt and scale in the fiercely competitive international AM market.

Critically, TPM3D systems were the first in China to receive CE certification from TÜV Rheinland Germany in 2016, a vital achievement that establishes world-class safety and quality standards, making their industrial equipment viable for deployment in regulated markets worldwide.

Technical Deep Dive: The Foundation of Selective Laser Sintering Excellence

For industrial engineers and procurement specialists, the foundational mechanics and material science capabilities of an sls printer are central to any evaluation. The robustness of the final component depends entirely on the control and optimization of the sintering process.

Material Science

SLS technology traditionally supports a wide array of thermoplastic materials, including polyamides (such as PA12 and PA11), ABS, polycarbonates, and nylons.

PA12 and PA6, specifically, have been extensively employed due to their favorable printability, processability, and inherent crystalline structure.

However, these traditional thermoplastic-based materials face inherent structural limitations. The lack of robust polymer inter-chain bonding often results in parts with inferior mechanical and thermal properties, and relatively low fatigue behavior.

These limitations constrain the use of SLS parts in high-stress, high-temperature, or long-lifetime industrial applications.

TPM3D’s strategy addresses this challenge by supporting an expansive portfolio of advanced and composite materials, ensuring specialized solutions for varied sectors. The company offers over 20 types of polymer powders, including PA12, PA11, PA6X, TPU, and PP, as well as crucial high-temperature and high-performance materials such as Polyetherketoneketone (PEKK) and Polyether Ether Ketone (PEEK).

Scaling Production: Large-Format, Dual-Laser Architecture

As the market continues to place exponentially higher demands on forming volume and printing efficiency, the architecture of the sls printer must evolve to deliver higher throughput, which is a key performance indicator of industrial SLS equipment. TPM3D has positioned itself strategically within the market by focusing on industrial, large-format systems.

Meeting the Demand for Volume and Velocity

Many legacy SLS systems offer build volumes that restrict their utility to batch production or smaller components.

TPM3D has differentiated its offerings by specializing in large-format industrial SLS solutions. The company’s flagship model, the S600DL, stands out with a huge build volume of 600 x 600 x 800 mm.

This size is significant because it represents one of the largest build volumes available in the market, contrasting sharply with many competitive SLS systems that feature notably smaller chambers.

To maximize the efficiency of such large volumes, TPM3D employs Dual-Laser technology in models such as the P550DL and S600DL.

The use of dual lasers enables simultaneous sintering across the expansive powder bed, significantly accelerating the printing process and maximizing productivity.

For instance, the P550DL dual-laser system, operating with layer thicknesses of 0.15 mm and a scan speeds up to 22 m/s, can produce up to 90 footwear components of varying designs in a single 38-hour build. This demonstrates the high-throughput capability essential for sectors like consumer goods and automotive manufacturing.

Competitive Throughput Analysis

A recognized challenge with these large-format systems is the significantly longer cool-down period required before parts are ready for post-processing. This prolonged cool-down extends the total cycle time for parts, offsetting initial gains in print speed.

TPM3D’s utilization of large volumes combined with high-speed dual-laser technology is a direct engineering response to this throughput challenge.

By simultaneously working across the bed, the dual-laser architecture shortens the base print time, thus focusing on maximizing the total cycle efficiency for high-volume, large-format jobs. This focus on maximizing productivity is critical for users seeking rapid Return on Investment (ROI) in serial production environments.

The following table provides a structural overview of TPM3D’s industrial SLS portfolio, demonstrating the company’s strategic commitment to scale and high-speed processing.

| Model Series | Key Feature | Build Volume (mm) | Laser Configuration | Primary Intent |

| P550DL | Cost-Effective, Scalable Production | 550 x 550 x 850 mm | Dual-Laser | Footwear, Consumer Goods, Electronics, and more |

| S600DL | Flagship Industrial Scale, High Throughput 6 | 600 x 600 x 800 mm | Dual-Laser | Automotive, Aerospace, Large Jigs, Medical, and more |

Beyond the Machine: Workflow and Efficiency in a Smart Factory Environment

A true industrial sls printer solution extends beyond the build chamber to encompass the entire workflow, particularly powder management and post-processing. These ancillary operations are often the hidden bottlenecks that dictate operational efficiency and Total Cost of Ownership (TCO).

Optimizing Material Management and Cost Efficiency

The primary operational cost factor in polymer AM is material consumption. In SLS, not all powder is sintered; a significant volume of unsintered powder remains after each job.

The cost-efficiency of SLS is highly dependent on the powder refresh rate, defined as the minimum ratio of fresh (virgin) powder that must be mixed with pre-used, unsintered powder to maintain optimal printing quality.

A lower refresh rate translates directly into superior cost-efficiency by maximizing material reuse.

TPM3D supports this by offering a broad material portfolio (over 20 polymer types) engineered for compatibility and efficient recycling.

The Integrated Solution: Powder Processing Station (PPS)

Traditional powder handling processes are often manual, messy, time-consuming, and carry occupational health risks due to dust exposure. These challenges introduce labor overhead and inconsistent results, undermining the efficiency gains of high-speed printing.

To solve this systemic industrial challenge, TPM3D developed the integrated Powder Processing Station (PPS). This single, enclosed system addresses the critical pain points in the post-print workflow by integrating six key functions: part cleaning, powder recovery, new powder loading, material mixing, automatic powder feeding, and dust collection.

The PPS transforms a manual, multi-station procedure into an efficient, automated sequence.

The PPS is engineered to create a synergy with the printer systems. By automating material mixing and recovery, the PPS supports the company’s commitment to achieving low powder refresh rates, directly minimizing material waste and labor costs.

This streamlined workflow is essential for integrating the high-speed S- and P-Series printers into a scalable, industrial smart factory environment.

Safety, Compliance, and Zone 22 Dust Explosion-Proof Standards

For industrial technology to be globally viable, adherence to international safety and quality standards is mandatory.

The PPS ensures clean and safe operation through rigorous compliance measures. The system’s dust emissions meet demanding standards, including ASHRAE H15 and China GB/T 14295 for sub-high-efficiency air filtration, making the setup suitable even for cleanroom environments.

Crucially, the entire PPS system is certified for industrial safety, holding the essential CE safety certification and meeting Zone 22 dust explosion-proof standards.

Attaining the Zone 22 certification, which governs the protection against hazardous explosive atmospheres generated by fine polymer powders, is a critical regulatory milestone.

By securing this certification alongside CE validation, TPM3D demonstrates that its systems are designed for dependable, long-term use in highly regulated global manufacturing settings, mitigating regulatory risk, and ensuring operator safety.

Industrial Validation: 82% Weight Reduction & 50% Lead Time Reduction in Automotive

The definitive validation of an industrial sls printer lies in its proven ability to generate quantifiable ROI across diverse, mission-critical applications. TPM3D systems have demonstrated substantial impact in sectors ranging from automotive to consumer goods.

Flagship Automotive Validation: The Dubai Autonomous Police Car

The automotive industry consistently demands precision, efficiency, and light weight, making it an ideal proving ground for advanced additive manufacturing. A key case study involved the manufacturing of structural and body parts for a self-driving micro police car deployed in Dubai.

The project utilized the large-format TPM3D S600DL system combined with robust glass-filled PA12 material. The benefits realized by the client were highly metric-driven and validated the technological shift from traditional manufacturing:

- Process Simplification: The traditional method for producing these parts required complex steps involving cutting machines and welding, resulting in a cumbersome workflow. By switching to the S600DL solution, the process was simplified to design followed directly by 3D printing, significantly enhancing efficiency and simplifying production.

- Lead Time Reduction: The simplified workflow directly translated into massive time savings. The lead time for parts production was reduced to only 2 days, representing a 50% reduction compared to conventional methods.

- Weight Reduction: Additive manufacturing’s design freedom allowed for topology optimization. The original front part of the vehicle, manufactured traditionally, weighed 27 kg. Using the SLS process, the weight was reduced to just 4 kg, achieving a dramatic 82% weight reduction. This massive reduction in mass is a critical factor for improving the energy efficiency and performance of autonomous and electric vehicles.

Revolutionizing Footwear and Consumer Goods

TPM3D has actively driven the digital transformation of the footwear industry, offering solutions that enhance design freedom and improve production efficiency.

SLS is ideally suited for footwear components, such as midsoles, because it enables the creation of intricate lattice and hollowed designs that are lightweight and breathable, without the constraints of traditional molds or the need for support structures.

The high-efficiency production capability is demonstrated by the P550DL system, which, as previously noted, can produce up to 90 shoes in a single 38-hour build. This capability supports digital footwear solutions that reduce the production time per shoe to as little as 25 minutes.

Diverse Industrial Applications

The breadth of applications validates the versatility of the TPM3D sls printer portfolio.

In the healthcare sector, the technology is essential for generating patient-specific products, including custom orthotics and 3D-printed glasses.

For industrial manufacturing, SLS is used to redefine robotics manufacturing (creating intricate robotic arms and dexterous hands), and to improve the speed and precision of automotive jigs and fixtures.

Furthermore, SLS plays a crucial role in accelerating Research & Development (R&D) cycles, such as speeding up the R&D process for power tools, reinforcing its value across the entire product lifecycle, from rapid prototyping to high-volume end-part production.

Works cited

- TPM3D Launched Industrial Large-Format SLS 3D Printers, accessed on October 21, 2025, https://english.tpm3d.com/tpm3d-launched-industrial-large-format-sls-3d-printers/

- Selective Laser Sintering of Polymers: Process Parameters, Machine Learning Approaches, and Future Directions – MDPI, accessed on October 21, 2025, https://www.mdpi.com/2504-4494/8/5/197

- TPM3D Showcases at China 3D Printing Footwear Forum: SLS Technology Driving the Digital Transformation of the Footwear Industry, accessed on October 21, 2025, https://english.tpm3d.com/tpm3d-showcases-at-china-3d-printing-footwear-forum-sls-technology-driving-the-digital-transformation-of-the-footwear-industry/

- Professional SLS 3D Printer Company Since 1999 – TPM3D, accessed on October 21, 2025, https://english.tpm3d.com/about/

- Selective Laser Sintering of High-Temperature Thermoset Polymer – MDPI, accessed on October 21, 2025, https://www.mdpi.com/2504-477X/6/2/41

- TPM3D Brings Simplicity and Efficiency to Major Industries Through …, accessed on October 21, 2025, https://www.3dnatives.com/en/tpm3d-sls-3d-printing-021020244/

- TPM3D Talks Clean, Efficient SLS 3D Printing and Expanding Internationally – 3Dnatives, accessed on October 21, 2025, https://www.3dnatives.com/en/tpm3d-clean-efficient-sls-3d-printing-expanding-internationally-260220254/

- SLS 3D Printing Cost Analysis: Key Expense Insights – ZONGHENG3D, accessed on October 21, 2025, https://www.zongheng3d.com/sls-3d-printing-cost-analysis-understanding-the-expenses/

- How Much Does a 3D Printer Cost? – Formlabs, accessed on October 21, 2025, https://formlabs.com/blog/how-to-calculate-3d-printer-cost/

- Powder Processing Station (PPS) – TPM3D, accessed on October 21, 2025, https://english.tpm3d.com/product/part-powder-processing-station-pps/

- SLM 3D Printers | RP America, accessed on October 21, 2025, https://rpamerica.us/equipment/tpm3d/

- Formlabs Fuse 1+ 30W vs. EOS SLS 3D Printers, accessed on October 21, 2025, https://formlabs.com/compare/eos-sls-3d-printers-vs-formlabs-fuse-series/

- Cost-Effective SLS 3D Printers for Scalable Production-TPM3D, accessed on October 21, 2025, https://english.tpm3d.com/p-series-sls-3d-printers/

- SLS powder refresh rate – how to refresh powder for best quality prints – Sinterit, accessed on October 21, 2025, https://sinterit.com/blog/sls-technology/sls-powder-refresh-rate-how-to-refresh-powder/

- What Are 3D Printer Prices For Popular AM Technologies? – Manufactur3D, accessed on October 21, 2025, https://manufactur3dmag.com/what-are-3d-printer-prices-technologies/

- TPM3D Brand Review: Industrial 3D Printing with Polyamides – Top 3D Shop, accessed on October 21, 2025, https://top3dshop.com/blog/tpm3d-brand-review-industrial-3d-printing-with-polyamides

- Case Study – TPM3D, accessed on October 21, 2025, https://english.tpm3d.com/category/case-study/

- Contact Us – TPM3D, accessed on October 21, 2025, https://english.tpm3d.com/contact-us/