Selective Laser Sintering (SLS) is rapidly transforming the landscape of modern manufacturing. This powerful 3D printing used to be only for large industrial companies. Now it is more accessible. Engineers, designers, and businesses can directly turn digital designs into durable, production-quality parts.

As a key pillar of additive manufacturing, SLS technology unlocks unprecedented design freedom and production efficiency. The global SLS 3D printing service market is a testament to this growth, valued at approximately USD 1.5 billion in 2023 and projected to surge to USD 5.8 billion by 2032, as noted by Dataintelo.

This guide will be your full resource. It covers the core technology, main benefits, material options, printer models, and the real costs of using this important technology.

Introduction: Unlocking Advanced Manufacturing with SLS 3D Printing

What is Selective Laser Sintering (SLS)?

Selective Laser Sintering (SLS) is an additive manufacturing process that belongs to the powder bed fusion family of technologies. It uses a high-powered laser to selectively fuse, or sinter, powdered polymer material, layer by layer, to create a solid three-dimensional object.

Unlike many other 3D printing methods, the unsintered powder in the build chamber supports the object during printing, eliminating the need for dedicated support structures. This unique characteristic is fundamental to the technology’s primary benefits.

Why This Guide is Essential for You: Navigating the SLS Landscape

Choosing the right manufacturing technology is a critical decision. The market for SLS 3D printers is expanding, with options ranging from compact benchtop systems to large-scale industrial machines. Understanding the nuances of the technology, the capabilities of different materials, and the total cost of ownership is essential for making an informed investment. This guide provides a clear, structured overview to help you determine if SLS is the right solution for your prototyping, tooling, or end-use part production needs.

Understanding SLS Technology: How It Works and Why It’s Unique

The Core Principle: Powder Bed Fusion and Selective Laser Sintering

The SLS 3D printing process begins with a 3D CAD model that is digitally sliced into thin cross-sections. The workflow inside the 3D printer follows a precise cycle for each layer. First, a thin layer of polymer powder is spread evenly across a build platform by a recoater blade. The build chamber is heated to a temperature just below the material’s melting point to minimize thermal distortion and facilitate fusion.

A powerful CO2 laser then scans the cross-section of the part for that layer, selectively raising the temperature of the powder particles to their melting point and fusing them together. Once a layer is complete, the build platform lowers by one layer thickness—typically 100-120 microns—and the process repeats. This cycle continues until the entire object is formed within the powder bed.

Key Components of an SLS 3D Printer

An SLS system is composed of several critical components working in unison:

- Build Chamber: An enclosed, heated chamber that houses the powder bed and the parts being printed.

- Laser System: A high-powered laser (typically CO2) and a galvanometer system that directs the beam with extreme precision.

- Powder Handling System: Includes a powder hopper, a recoater to spread fresh layers, and often a system for feeding new material.

- Heaters and Sensors: Maintain a consistent and precise temperature throughout the build chamber, which is crucial for part quality and dimensional accuracy.

- Control System: The software and hardware that interpret the digital file and orchestrate the printing process.

SLS vs. Other 3D Printing Technologies (Brief Comparison)

SLS technology stands apart from other common 3D printing methods:

- vs. Fused Deposition Modeling (FDM): FDM extrudes thermoplastic filaments layer by layer. While affordable, FDM parts are anisotropic (weaker between layers) and often require extensive support structures, limiting geometric complexity. SLS produces parts with near-isotropic mechanical properties and needs no supports.

- vs. Stereolithography (SLA): SLA cures liquid photopolymer resins with a UV laser, offering high detail and smooth surfaces. However, parts can be brittle, and the process requires extensive support structures and post-curing. SLS excels in producing tough, durable functional parts without the hassle of supports.

Key Benefits of SLS 3D Printing: Why It’s a Game Changer for Diverse Industries

Superior Part Quality and Performance

SLS 3D printing is celebrated for delivering parts with superior mechanical properties akin to those achieved through traditional injection molding. The process produces robust, dense parts with high tensile strength and outstanding durability, making them ideal for rigorous functional testing and use as end-use components. This capability is empowered by companies like TPM3D, a pioneer in SLS technology, which offers a range of advanced 3D printing systems and materials to support industries such as healthcare, automotive, and aerospace.

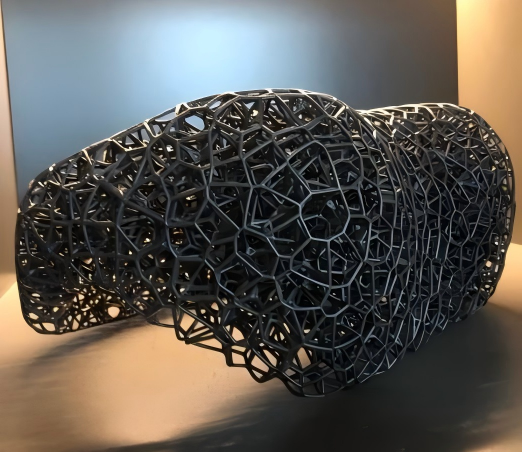

Unparalleled Design Freedom and Geometric Complexity

The most significant advantage of SLS technology is the elimination of dedicated support structures. The unsintered powder in the build chamber acts as a natural support system, allowing for the creation of intricate internal channels, complex undercuts, and features that would be impossible to manufacture with other methods. This frees designers and engineers from the constraints of traditional manufacturing.

High-Throughput Production and Efficiency

Because no support structures are required, the entire build volume of an SLS 3D printer can be utilized by nesting multiple parts together in a single build. This “packing” capability dramatically increases throughput and reduces the cost per part, making SLS a highly efficient solution for small- to medium-batch production runs. After printing, the parts simply need to be excavated from the surrounding powder cake.

Material Versatility for Broad Applications (e.g., automotive, medical, R&D environments)

SLS supports a growing range of robust thermoplastic materials, each with unique properties tailored for specific applications. SLS uses tough and versatile nylons for automotive jigs and fixtures. It also uses flexible materials for wearables and biocompatible types for medical devices. This material variety serves many demanding industries. This adaptability makes it a valuable tool in R&D environments for creating functional prototypes that closely mimic final production parts.

Exploring SLS Materials: Powering Diverse Applications

The choice of material is fundamental to the success of any 3D printing application. SLS technology leverages a range of high-performance polymer powders to create functional parts.

The Dominance of Polyamides (Nylon Materials)

Polyamides (PAs), commonly known as nylons, are the workhorse material for SLS 3D printing.

- PA12 (Nylon 12): Nylon 12 stands out for its excellent combination of strength, stiffness, and toughness. It is highly valued for its chemical resistance and low moisture absorption, making it ideal for both functional prototypes and end-use parts.

- Nylon 12 Variants

Brands like TPM3D offer various Nylon 12 options to meet diverse industry requirements: - – Precimid 1171Pro | Biocompatible White Nylon 12: This biocompatible powder is perfect for medical and clinical applications, meeting stringent safety standards such as USP Class VI and food-contact requirements. It is suitable for patient-contact devices, balancing mechanical properties like tensile and flexural strength, ensuring both safety and performance.

– Flame Retardant Nylon 12 Powders: Specifically designed for sectors like automotive and electronics, these variants offer flame resistance and maintain the mechanical strengths of standard PA12.

- PA11 (Nylon 11): Derived from renewable castor oil, PA11 offers superior elongation at break and impact resistance compared to PA12, making it perfect for applications requiring high ductility and durability, such as snap-fit enclosures and living hinges.

According to industry analysis, these foundational nylon powders can range from $40 to $100 per kilogram.

Flexible Materials: TPU-88A

Thermoplastic Polyurethane (TPU) is an elastomeric material used in SLS to create flexible, rubber-like parts. It offers excellent tear resistance and durability, making it suitable for applications like seals, gaskets, hoses, and shock absorbers.

Composite Materials for Enhanced Performance

To achieve specific mechanical or thermal properties, base polymers can be filled with additives:

- Glass-Filled Nylon (PA-GF): Adding glass fibers increases stiffness and thermal resistance, making it suitable for parts that need to withstand higher temperatures and loads.

- Carbon-Filled Nylon (PA-CF): Carbon fiber reinforcement significantly increases stiffness and strength while reducing weight, ideal for high-performance automotive and aerospace applications.

- Aluminum-Filled Nylon (Alumide): This composite contains aluminum powder, giving parts a metallic appearance and increased thermal conductivity.

High-Performance & Niche Materials

The SLS material range keeps growing. It now includes high-performance polymers like PEEK and PEKK. These are used in tough aerospace and medical applications that need high heat and chemical resistance. Biocompatible materials are also available for medical devices that require skin contact.

Understanding Material Properties and Their Impact on End-Use Parts

The properties of the selected material directly dictate the performance of the final part. Factors like tensile strength, elongation at break, thermal resistance, and chemical compatibility must be carefully considered during the design phase to ensure the end-use part meets all functional requirements.

A Look at SLS 3D Printer Models: From Benchtop to Industrial Power

The SLS 3D printer market has matured significantly, with systems available for various scales of operation. The overall market for SLS printers was valued at USD 1.2 billion in 2024 and is projected to reach USD 3.5 billion by 2034, according to Reports and Data.

Entry-Level / Benchtop SLS 3D Printers (Ideal for R&D, educational institutions, advanced prototyping)

These compact systems have made in-house SLS printing accessible to a much wider audience. With a smaller build volume and a lower price point, they are perfect for producing prototypes, small parts, and enabling rapid design iteration in office or lab environments. They provide a great way to start industrial-grade additive manufacturing. They do this without needing the large facilities that bigger machines require.

Mid-Range / Professional SLS Printers (For growing businesses, pilot production)

Bridging the gap between benchtop and full-scale industrial systems, mid-range printers offer a larger build volume, faster print speeds, and more advanced features like automated powder handling.

For instance, TPM3D’s CF200, part of their professional-grade C Series, is designed to integrate seamlessly into R&D labs or office environments, offering a compact size and automated workflow. These printers are ideal for businesses aiming to enhance production capabilities, manage pilot manufacturing lines, or deliver on-demand printing services efficiently.

Industrial-Grade SLS Systems (For high-throughput production, industrial clients)

At the top end are industrial-grade SLS systems designed for continuous operation and high-throughput production demands. Companies such as TPM3D offer solutions in this segment with their Superior Series (S Series) and Performance Series (P Series). These machines provide significant build volumes, exemplified by the S600DL, boasting a 600 x 600 x 800 mm build chamber, and utilize technologies like dual lasers to enhance productivity.

Key features, including efficient cooling systems and top-loaded powder handling, contribute to their operational efficiency and reliability, which are highly valued in demanding sectors like automotive and aerospace manufacturing.

These printers are well-suited for producing consistent, high-quality, end-use parts at scale, meeting the rigorous standards of various industries.

Demystifying SLS Costs: A Comprehensive Breakdown for Informed Investment

Understanding the full financial picture of SLS technology requires looking beyond the initial price tag of the 3D printer.

Initial Investment: The Printer Price Tag

The initial cost of an SLS 3D printer varies significantly based on its capabilities. Benchtop models generally range from $10,000 to $30,000, solid options for smaller-scale operations like R&D labs or design studios. Professional-grade systems are priced between $50,000 and $150,000, offering enhanced features suitable for pilot manufacturing and complex prototyping tasks. For high-throughput industrial applications, expect to invest several hundred thousand dollars in large-scale systems. Notably, TPM3D’s Performance and Superior Series models are designed to meet demanding industry standards in sectors such as automotive and aerospace.

Material Costs: A Significant Operating Expense

Powder is the primary consumable. The cost per kilogram varies by type (e.g., PA12, TPU, composites). An important factor is the “refresh rate”—the ratio of fresh powder that must be mixed with used, unsintered powder for the next build. A lower refresh rate means better material efficiency and lower operating costs.

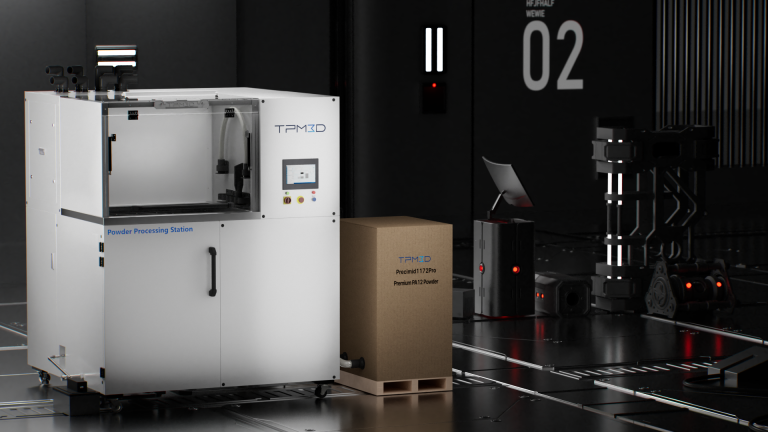

Post-Processing Equipment & Consumables

A comprehensive SLS workflow involves essential ancillary equipment, such as a powder processing station for part breakout and powder recovery, like TPM3D’s powder processing station. These stations incorporate sophisticated dust-collection and depowdering capabilities to streamline the powder handling process. Additionally, media blasters are utilized for cleaning fine powder residues from part surfaces. Consumables comprise media for the blaster and filters to ensure a clean and efficient operation.

Operational Costs: Power, Maintenance, and Training

SLS printers, particularly the heaters and lasers, consume a significant amount of electricity. Other costs include routine maintenance, service contracts for industrial systems, spare parts, and the initial training for operators to manage the full workflow safely and efficiently.

Total Cost of Ownership (TCO): Beyond the Sticker Price

TCO provides a holistic view by combining the initial investment with all ongoing operational expenses over the lifetime of the machine. When calculating TCO, factors like labor, material refresh rates, throughput, and maintenance are crucial for accurately determining the cost per part and the overall return on investment.

The SLS Workflow: From CAD File to Finished Part

The end-to-end process for creating a part with SLS technology is a systematic workflow:

- Design & Preparation: A 3D model is designed in CAD software. For SLS, designers can leverage the technology’s geometric freedom. The file is then imported into print preparation software, where parts are oriented and nested within the build volume to maximize efficiency.

- Printing: The prepared file is sent to the SLS 3D printer. The machine executes the build job, sintering the powder layer by layer. This process can take several hours to days, depending on the size and density of the build.

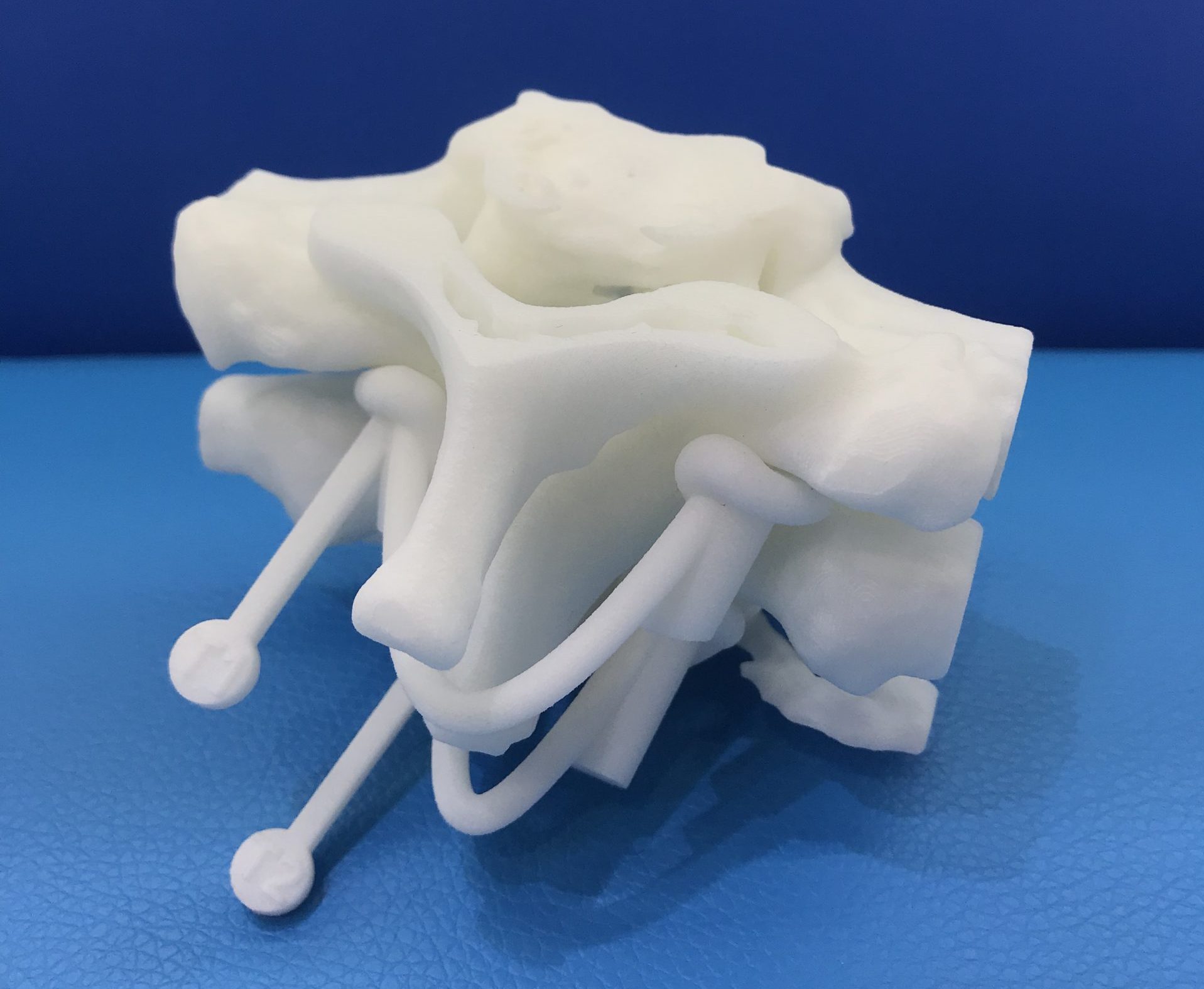

- Cooldown: After printing, the entire powder bed, containing the fused parts, must cool down slowly inside the machine to prevent warping and ensure dimensional accuracy. This can take as long as the print job itself.

- Part Breakout & Recovery: Once cooled, the build chamber is moved to a breakout station. The operator carefully excavates the finished parts from the loose, unsintered powder. The leftover powder is collected, sieved, and mixed with fresh material for reuse.

- Post-Processing: The excavated parts are cleaned to remove any residual powder. This is typically done with compressed air and then media blasting to achieve a final, clean surface finish. Parts can then undergo secondary processes like dyeing, painting, or coating if desired.

Conclusion: Impact and Applications of Selective Laser Sintering

Selective Laser Sintering has firmly established itself as a cornerstone of modern additive manufacturing. Its unique ability to produce strong, complex parts without the need for support structures provides unparalleled design freedom and production efficiency. The SLS ecosystem offers a scalable solution for many uses. It includes benchtop systems for small R&D teams and industrial machines for factory production in automotive and aerospace.

Businesses can understand the core technology, the range of materials, and the true total cost of ownership. This helps them make smart investments that speed up innovation, shorten supply chains, and create products that were once impossible to make. Whether you are looking to produce robust functional prototypes or scale up to low-volume production of end-use parts, exploring the capabilities of SLS 3D printers is a critical step toward unlocking the future of digital manufacturing. To move forward, check your specific application needs. Look at the build volume and material compatibility you need. Talk to technology providers to find the system that fits your production goals and budget.