3D printing, also known as additive manufacturing, has gained momentum in industries such as manufacturing, healthcare, and aerospace. With its rapid rise, many are asking: Can 3D printing replace traditional manufacturing?

The answer isn’t simple. Instead of being a complete substitute, 3D printing and traditional manufacturing often complement each other. This article explores their differences, advantages, limitations, and how both will shape the future of production.

Comparing 3D Printing and Traditional Manufacturing

-

Traditional Manufacturing: Best suited for mass production of identical products. It requires molds, tooling, large production lines, and significant investment in labor and resources.

-

3D Printing: A single 3D printer can produce different designs without molds, making it flexible and cost-effective for prototyping and small-batch production.

Traditional methods involve multiple steps—procurement, machining, assembly, and inspection—while 3D printing can often complete the process in one streamlined operation.

Advantages of 3D Printing Technology

-

Lower Production Costs

-

Minimal material waste since additive manufacturing uses only the material required.

-

Eliminates the need for molds and tooling.

-

-

Faster Prototyping and Iteration

-

Designers can create and test prototypes quickly, reducing product development cycles.

-

Design updates can be implemented without costly retooling.

-

-

Personalized and Customized Products

-

Unlike traditional mass production, 3D printing enables on-demand customization, improving customer satisfaction and product value.

-

-

Flexible Manufacturing

-

Switching between product designs is as simple as changing digital files.

-

Ideal for small-batch and diverse production needs.

-

-

Reduced Environmental Impact

-

Generates less scrap and emissions compared to subtractive methods.

-

Supports sustainable manufacturing practices.

-

Limitations of 3D Printing

-

High Equipment and Material Costs

-

Industrial 3D printers and high-performance powders or resins remain expensive.

-

-

Product Quality Challenges

-

Layer-by-layer printing may result in weaker mechanical properties compared to injection molding or CNC machining.

-

-

Slower for Mass Production

-

Traditional methods are still faster and more economical for producing millions of identical parts.

-

The Future: Integration, Not Replacement

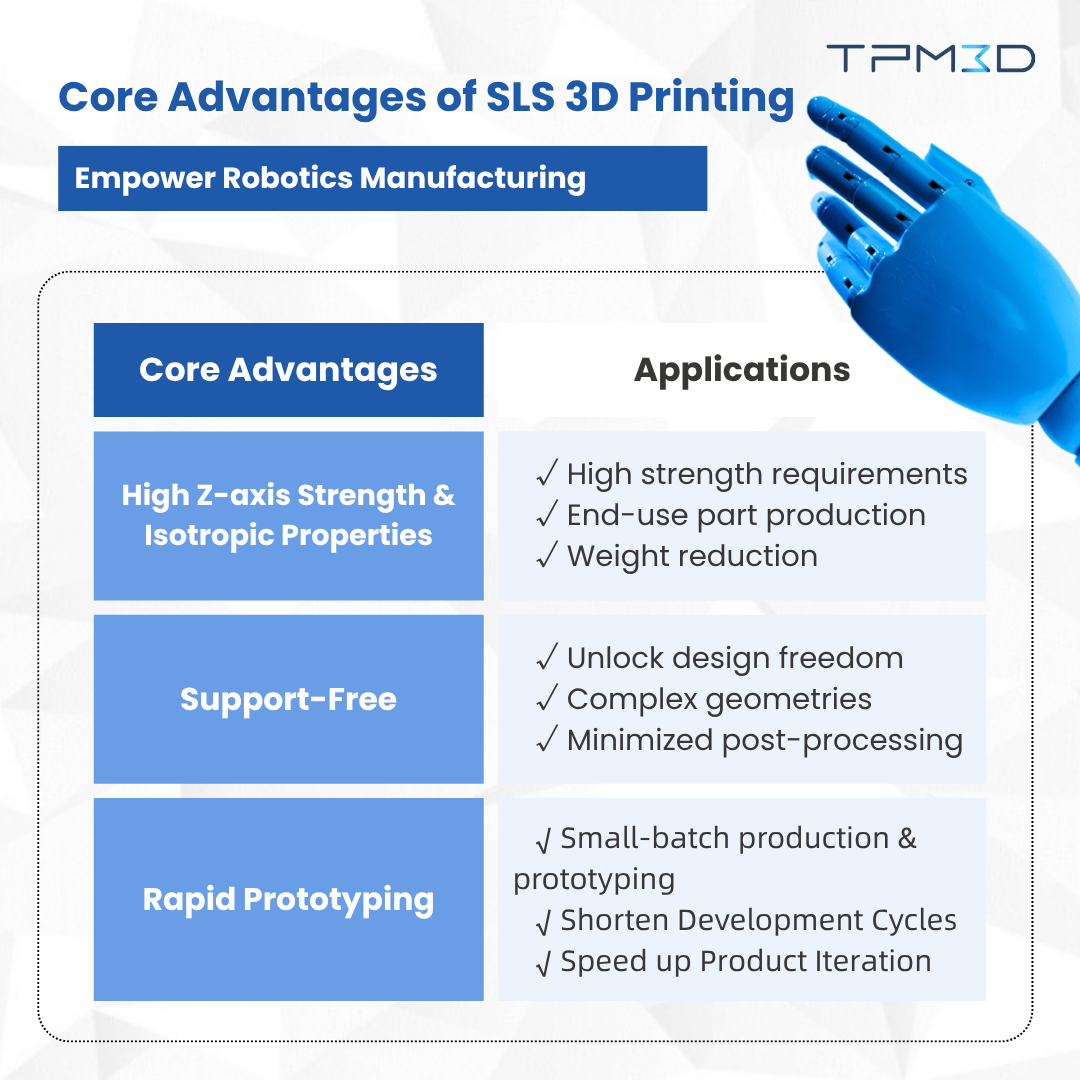

Currently, traditional manufacturing remains the backbone of mass production, ensuring stability and efficiency. However, 3D printing is advancing rapidly, especially with large-scale industrial printers such as SLS (Selective Laser Sintering) systems, which are moving closer to cost-effective batch production.

The most likely future is not replacement, but integration. Combining 3D printing’s flexibility and customization with the scalability of traditional manufacturing will enable smarter, more efficient, and sustainable production.

Conclusion

3D printing will not completely replace traditional manufacturing in the near term. Instead, it will continue to complement and enhance conventional methods, especially in areas like rapid prototyping, customization, and complex part production. As technology evolves, its role in mainstream manufacturing will expand, paving the way for a hybrid future of digital and traditional production methods working together.