Selective Laser Sintering (SLS) 3D printing is a powder-based additive manufacturing process that uses high-powered lasers to fuse polymer powders layer by layer. One common question is: Can SLS 3D printing be used with PP (polypropylene) materials? The answer is yes. Not only can SLS print PP, but it can also process a range of PP composite reinforced materials, making it a versatile and cost-effective solution across industries.

Why Use PP in SLS 3D Printing?

Compared with other 3D printing methods such as FDM and SLA (stereolithography), SLS printing with PP offers several unique advantages:

-

Low Anisotropy: Parts printed via SLS exhibit minimal anisotropy in the X, Y, and Z directions, ensuring more uniform mechanical properties.

-

No Support Structures Needed: Unsintered powder acts as a natural support, allowing for complex geometries without additional structures.

-

Cost-Effective: PP and PP composites are affordable materials with good overall performance.

-

Wide Applications: Ideal for rapid prototyping, medical devices, product design, and small-batch customization.

Applications of SLS 3D Printing with PP

1. Complex Pipes and Joints

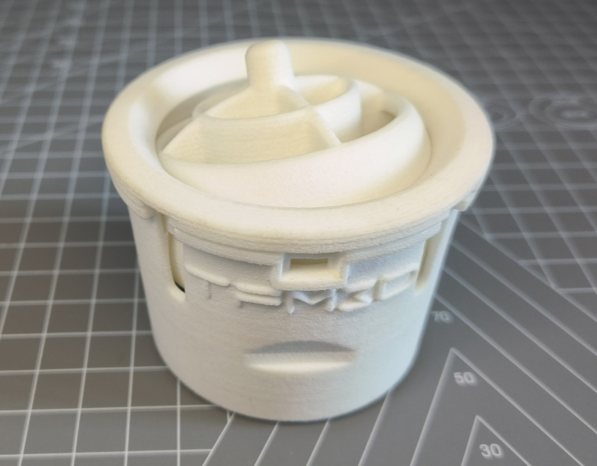

PP materials are extremely stable in water, with an absorption rate of only 0.01%. This makes them perfect for printing irregular pipelines and joints, especially in industries that require water-resistant components.

Example: PP printed irregular pipelines and joints using TPM3D SLS technology.

2. Medical Rehabilitation Devices

Thanks to its toughness and secondary shaping ability, PP is widely applied in the medical rehabilitation field. It is used for products such as finger braces, wrist supports, and postoperative fixation devices.

Example: A PP wrist protector 3D printed with a TPM3D SLS printer.

3. Automotive Parts with PP Composites

PP fiberglass composites combine lightweight properties with excellent toughness, making them a popular choice in the automotive industry. Many interior and exterior car parts are already manufactured using PP powders via SLS 3D printing.

Conclusion

Yes, SLS 3D printing technology can print PP materials and their composites. From complex pipeline components to customized medical devices and automotive applications, PP brings durability, water resistance, and cost efficiency to additive manufacturing. As SLS technology continues to advance, PP will play an even greater role in industrial applications.