Scoliosis is a spinal deformity that can be broadly categorized into non-structural and structural scoliosis. Non-structural scoliosis is temporary, often caused by factors like muscle imbalance or injury, and resolves when the cause is removed. Structural scoliosis, on the other hand, is permanent and may progress over time. Among structural cases, idiopathic scoliosis is the most common, accounting for 75–85% of patients, with adolescent idiopathic scoliosis being particularly prevalent.

Spinal curves often appear in C-shaped or S-shaped patterns, affecting posture, balance, and potentially leading to long-term health issues if left untreated.

Traditional Orthoses: Challenges in Conservative Scoliosis Care

Brace therapy remains the primary conservative treatment for scoliosis patients, particularly those with spinal curvature between 20° and 40° or adolescents whose curves progress rapidly.

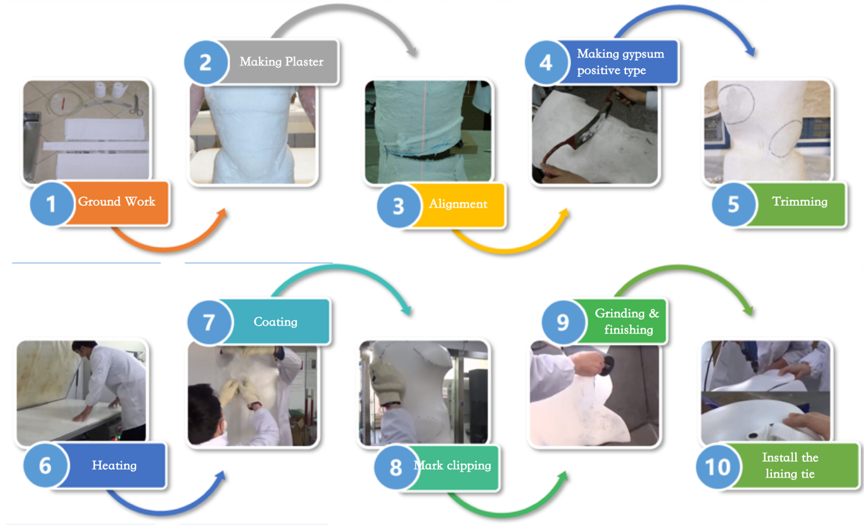

Traditional scoliosis braces are manufactured using a labor-intensive process:

-

Gypsum molding of the patient’s torso

-

Repairing and shaping the mold

-

Thermoplastic plate attachment

-

Trimming, polishing, and lining installation

While this method is cost-effective and allows some adjustment through reheating or trimming, it presents significant challenges:

-

Low production efficiency: Orthotists can make only 3–5 braces per day.

-

Cumbersome process: Requires the patient to participate actively during molding.

-

Bulky design: Large braces are uncomfortable, difficult to hide, and may interfere with daily activities and schooling.

SLS 3D Printing: A Precise and Efficient Solution

In 2021, the 3D Printing Digital Medical Center at Zhongshan Chenxinghai Hospital began leveraging TPM3D’s SLS (Selective Laser Sintering) 3D printing technology for scoliosis braces and other orthopedic devices. This technology allows rapid, contactless, and highly accurate customization while improving patient comfort and treatment outcomes.

Manufacturing process of traditional scoliosis orthosis

Case Study: Custom 3D-Printed Scoliosis Orthosis

Patient Profile:

-

13-year-old girl

-

Thoracic scoliosis: 15°

-

Lumbar scoliosis: 23°

-

Progressive curvature year by year

Treatment Plan: Custom nylon SLS 3D-printed orthosis

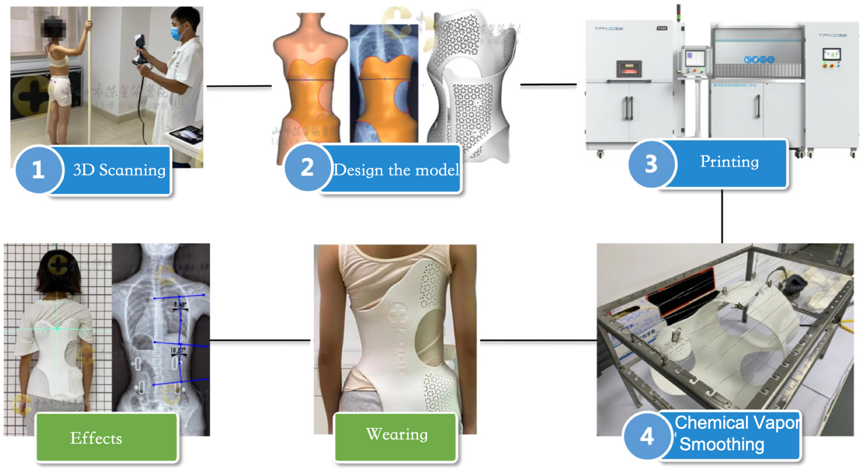

Production Workflow:

-

3D Scanning: A fast, non-contact scan captures precise spinal and torso anatomy.

-

Digital Design: Orthosis models are modified for optimal comfort, fit, and corrective force, incorporating patient-specific features.

-

SLS Printing: Using TPM3D P360 system and Precimid1172Pro PA12 nylon powder, the brace is printed. The material offers:

-

High mechanical strength

-

Excellent durability and fatigue resistance

-

Wear-resistance for long-term use

-

Lightweight and breathable design

-

Manufacturing process of 3D printing scoliosis orthosis

For larger or multiple braces, TPM3D S480 or P550DL systems enable simultaneous multi-part production.

-

Post-Processing: Chemical Vapor Smoothing is applied to create a smooth, tough, waterproof, and hygienic surface, reducing bacterial growth and enhancing comfort.

-

Final Assembly: Linings and fastening straps are installed, ready for patient use.

Total Production Time: Approximately 2 days, compared to several weeks for traditional orthoses.

Clinical Outcomes

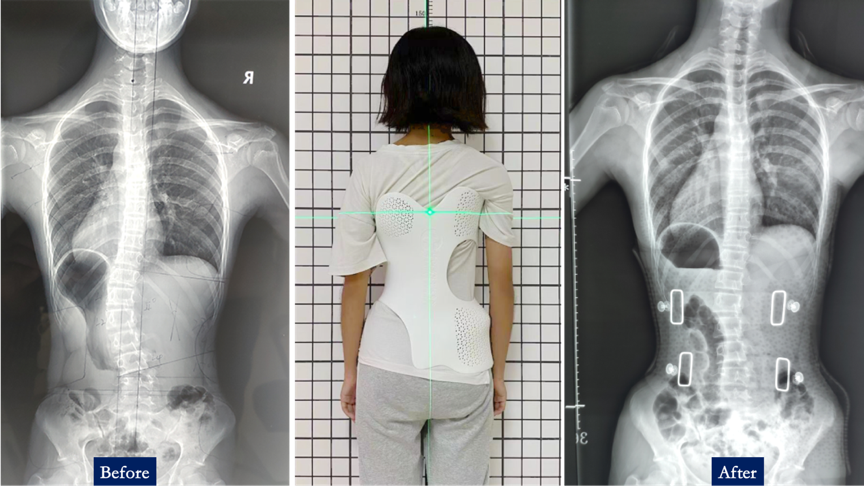

Post-treatment X-rays show remarkable improvement:

-

Thoracic curve: Corrected from 15° to 9°

-

Lumbar curve: Corrected from 23° to 11°

-

Correction Rate: Over 50% for lateral curvature

-

Additional Improvements: Vertebral rotation, pelvic tilt, and trunk balance significantly enhanced

The patient also reported better comfort, lighter weight, and improved mobility, highlighting the practical advantages of SLS 3D-printed orthoses.

Radiographs of patients before and after wearing 3d printed orthosis

Advantages of SLS 3D-Printed Scoliosis Orthoses

-

Precision Fit: Digital scanning ensures the orthosis matches the patient’s anatomy precisely.

-

Lightweight and Breathable: Nylon PA12 allows hollow designs for ventilation without compromising strength.

-

Faster Production: Reduced from weeks to just a few days.

-

Durable and Hygienic: Chemical vapor smoothing makes the surface waterproof, bacteria-resistant, and easy to clean.

-

Scalable Manufacturing: Large-volume or multi-brace printing is possible with advanced SLS systems.

-

Enhanced Patient Compliance: Smaller, aesthetically pleasing braces improve adherence, especially for adolescents.

Conclusion

SLS 3D printing is transforming scoliosis treatment by combining rapid digital manufacturing, precise customization, and superior comfort. Patients receive braces faster, with improved fit and effectiveness, while orthotists gain a more efficient and reliable production workflow. This technology represents a significant advancement in conservative scoliosis care, aligning perfectly with modern precision medicine and digital healthcare trends.