The Basilica of Santa Maria della Salute, built in the 17th century, is one of Venice’s most iconic landmarks. With its long history, intricate details, and striking Baroque style, it remains a must-visit destination for travelers worldwide. Today, this architectural masterpiece takes on a new life—not in stone, but through the advanced capabilities of Selective Laser Sintering (SLS) 3D printing.

A Challenging Architectural Model

The scale of the project was ambitious: a model measuring 470 × 400 × 577 mm and weighing nearly 7 kg. The church’s upper structure and dome were divided into quarter sections to preserve its delicate geometry. Details such as stairs, suspended beams, columns, and railings—some as thin as 0.6 mm—pushed the limits of printing precision.

This combination of large size and fine detail made the model an extraordinary challenge. It required equipment with both excellent accuracy for small features and robust stability to handle large, heavy prints.

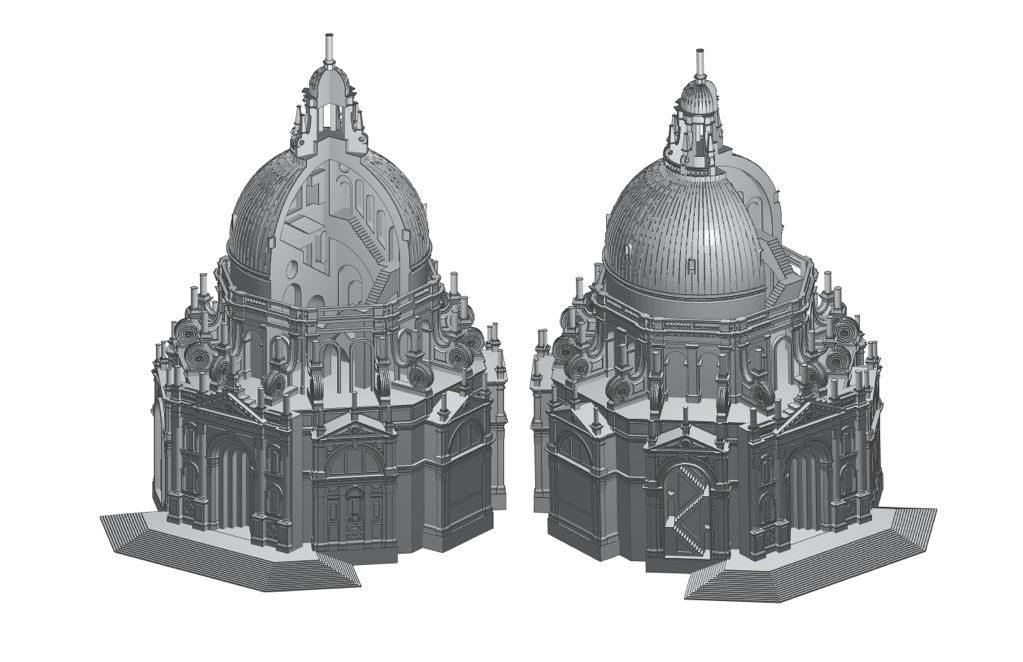

3D model of the Basilica of Santa Maria della Salute

The Power of the S600DL and PPS

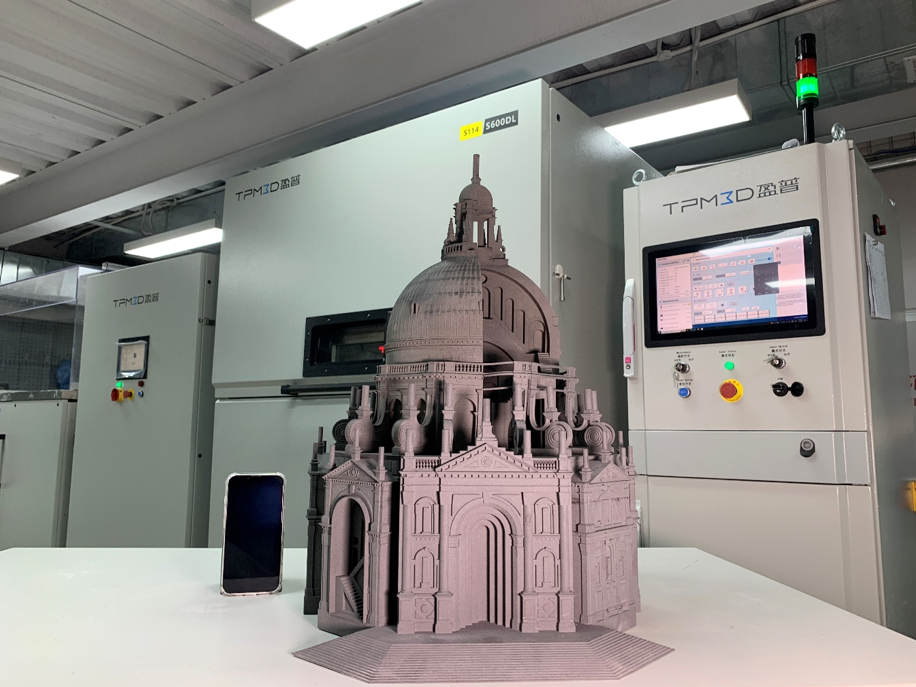

To meet this challenge, we selected the Yingpu S600DL dual-laser flagship SLS printer. With a massive build cylinder of 600 × 600 × 800 mm (288 liters), it is one of the largest industrial-grade SLS systems available. Its well-balanced XYZ design ensures precision across the entire build volume, even for complex architectural projects.

For post-processing, we relied on the TPM3D Part & Powder Processing Station (PPS). This integrated system combines six key functions—part cleaning, powder recycling, powder intake, powder mixing, powder feeding, and dust collection.

By improving efficiency and reducing powder leakage, PPS ensures a safer, cleaner, and more cost-effective workflow. Beyond architecture, this system is already creating value for industries such as automotive, aerospace, defense, and healthcare.

TPM3D S600DL +PPS clean production scheme

Protecting the Fine Details

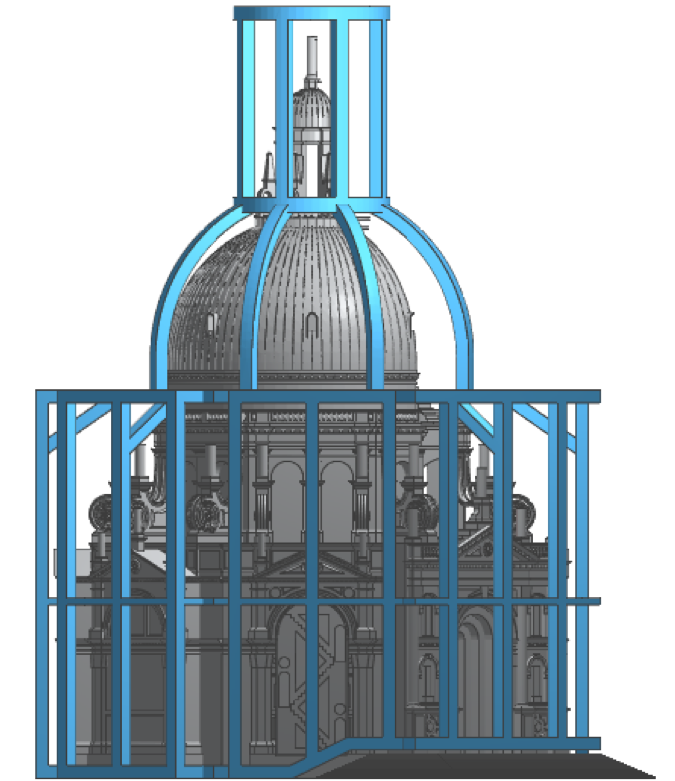

Given the delicate features of the Basilica model, there was a risk of damage during powder cleaning and transport. To safeguard the print, engineers designed and printed a protective cage around the church model itself. This innovative solution added to the overall size and weight but ensured that the model’s intricate details remained intact from start to finish.

Engineers designed and printed a protective cage around the church model

From Printing to Finishing

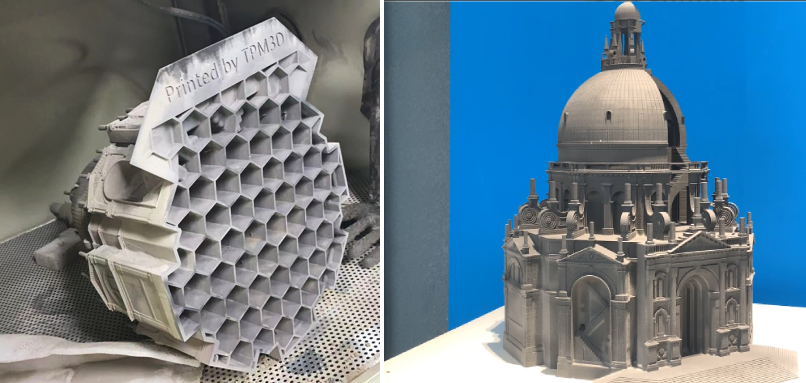

The printing process used intelligent dual-laser collaborative scanning, completing the full build in just 23 hours. Due to the size and weight of the part, an electric cart was required for powder cleaning.

After depowdering, the model underwent surface treatment with a large sandblasting machine, which enhanced its texture and finish. Even after simple post-processing, the model revealed exceptional accuracy, strength, and aesthetic fidelity.

During and after sandblasting

A Perfect Union of Technology and Art

The result is a faithful reproduction of the Basilica of Santa Maria della Salute, capturing the elegance of its Baroque style with remarkable precision. From its dome to its staircases, every detail reflects the capabilities of SLS technology in combining scale, accuracy, and durability.

This project not only demonstrates how SLS printing can bring historical architecture to life but also showcases its potential in fields where large, complex, and highly detailed parts are essential.

Through the integration of the S600DL printer and PPS system, TPM3D proves once again how advanced additive manufacturing can transform visionary designs into tangible masterpieces.