As precision medicine and digital healthcare continue to evolve, 3D printing is transforming the medical field, particularly in digital rehabilitation and orthopedic care.

Selective Laser Sintering (SLS) 3D printing offers unique advantages, including precise customization, lightweight design, breathability, and rapid production, making it increasingly popular among orthopedic patients and rehabilitation centers.

TPM3D, a leading manufacturer of laser sintering equipment, has partnered with the Translational Medicine Research Institute of Shanghai Jiao Tong University and Chen Xinghai Hospital to establish a dedicated 3D Printing Medical Application Center.

The center focuses on digital rehabilitation solutions, integrating professional evaluation, data collection, design modification, post-printing processing, and precise fitting. Since its launch, the center has developed more than ten types of orthopedic and rehabilitation products, accumulating numerous successful cases.

1. Scoliosis Brace

Using 3D scanning and SLS 3D printing, scoliosis braces are produced with fewer steps and rapid, contactless molding. The finished braces are lightweight, compact, breathable, durable, and aesthetically pleasing, offering superior comfort for teenagers. In August last year, TPM3D’s scoliosis brace production was recognized by China’s Ministry of Industry and Information Technology as a model application of additive manufacturing.

2. Thoracolumbar Support

The center provides thoracolumbar supports for spine surgery patients of all ages. For example, an 82-year-old retired teacher who would traditionally need to stay in bed for 6–8 weeks after a spinal fracture was able to reduce bedridden time to just 3 weeks using an SLS 3D printed support.

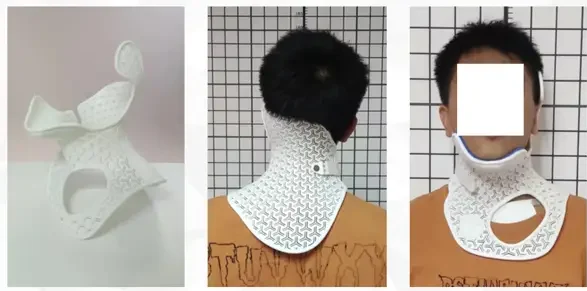

3. Neck Support

For cervical surgeries or other neck operations, the center developed neck supports that allow openings for dressing changes and can be designed with hollow structures for better ventilation and comfort.

4. Ankle Orthosis

Ankle orthoses help control joint movement, support fractures, arthritis, or deformities, and traditionally offer limited customization. SLS 3D printing allows lightweight, hollow designs, precise fit, and strong, durable nylon material, ensuring both comfort and orthopedic effectiveness.

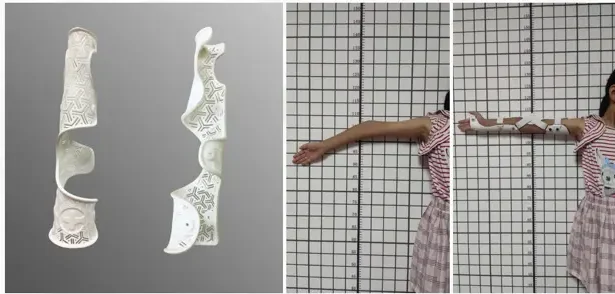

5. Elbow Orthosis

Elbow orthoses correct internal or external rotation in adolescents. Produced with SLS 3D printing, they offer excellent orthopedic effects while remaining lightweight, breathable, and comfortable.

6. Wrist Support

Wrist supports stabilize and protect patients’ wrists after surgery. For example, a doctor who ruptured a tendon while playing basketball was able to recover effectively with a printed wrist support.

7. Hip Orthosis

For children with femoral midshaft fractures, traditional hip supports are difficult to find. The center designs customized SLS 3D printed hip supports to provide optimal fit, protection, and comfort for even the youngest patients.

8. Orthopedic Insoles

Using plantar pressure testing and gait analysis, the center produces personalized insoles for patients with cerebral palsy, diabetes, flat feet, or foot deformities. These insoles improve walking stability and lower limb alignment while providing effective support.

9. Rehabilitation Pillow

Long hours of looking at screens often cause neck strain and stiffness. In collaboration with BASF, the center developed a lightweight 3D printed air pillow using topology optimization. The pillow provides strong, elastic, waterproof, and antibacterial support, relieving neck muscle tension and improving sleep quality, while gradually restoring proper neck alignment.

Expanding Digital Rehabilitation

In addition to these nine categories, the center also produces knee orthoses, postoperative fixation aids, and other digital rehabilitation products. TPM3D continues to advance SLS 3D printing technology to improve precision, comfort, and accessibility in rehabilitation and orthopedic care.