At TPM3D, we know that the success of any additive manufacturing project often comes down to the material. For applications where strength, durability, and thermal stability are essential—not optional—we developed Precimid1174Pro CF: a carbon fiber-reinforced Nylon 12 tailored for the real-world needs of the automotive, aerospace, UAV, robotics, and electronics industries.

This high-performance SLS powder balances low weight with outstanding mechanical and thermal properties, offering a practical solution for producing strong, reliable parts that hold up under pressure, heat, and wear.

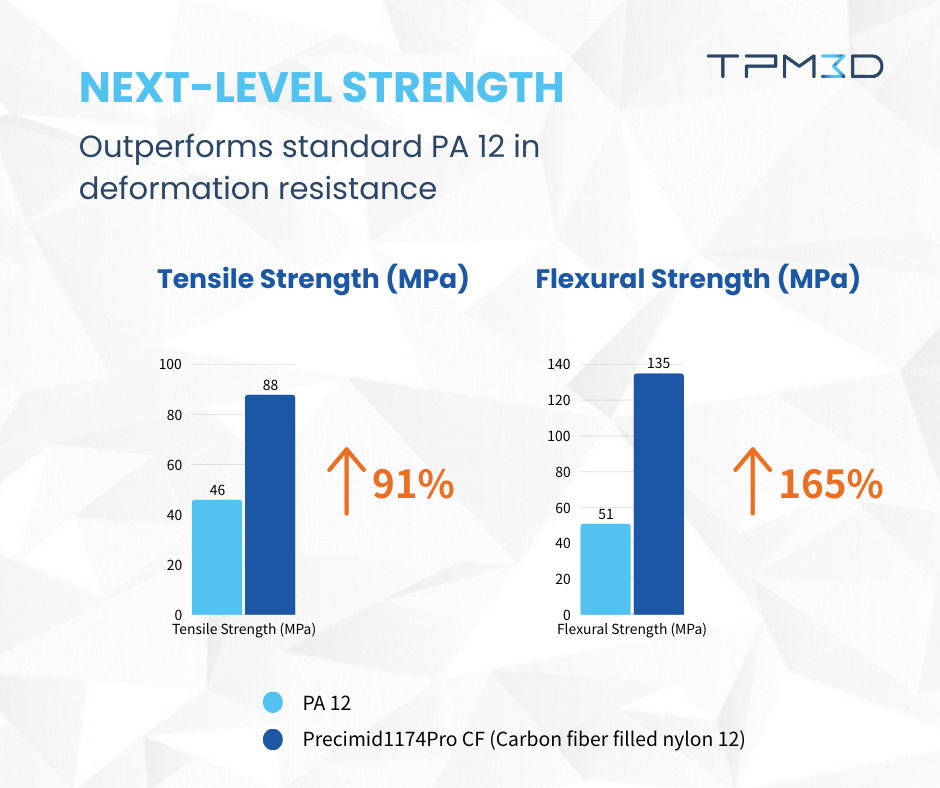

Enhanced Performance

Reinforced with short carbon fibers, Precimid1174Pro CF delivers major performance gains over standard PA12. Mechanical tests show: ·Tensile strength: 88 MPa (up 91%) ·Flexural strength: 135 MPa (up 165%) ·Tensile modulus: 9000 MPa (up 389%) ·Flexural modulus: 6000 MPa (up 369%) These upgrades translate into better load-bearing capability, enhanced rigidity, and resistance to deformation—ideal for structural and functional parts in demanding applications.

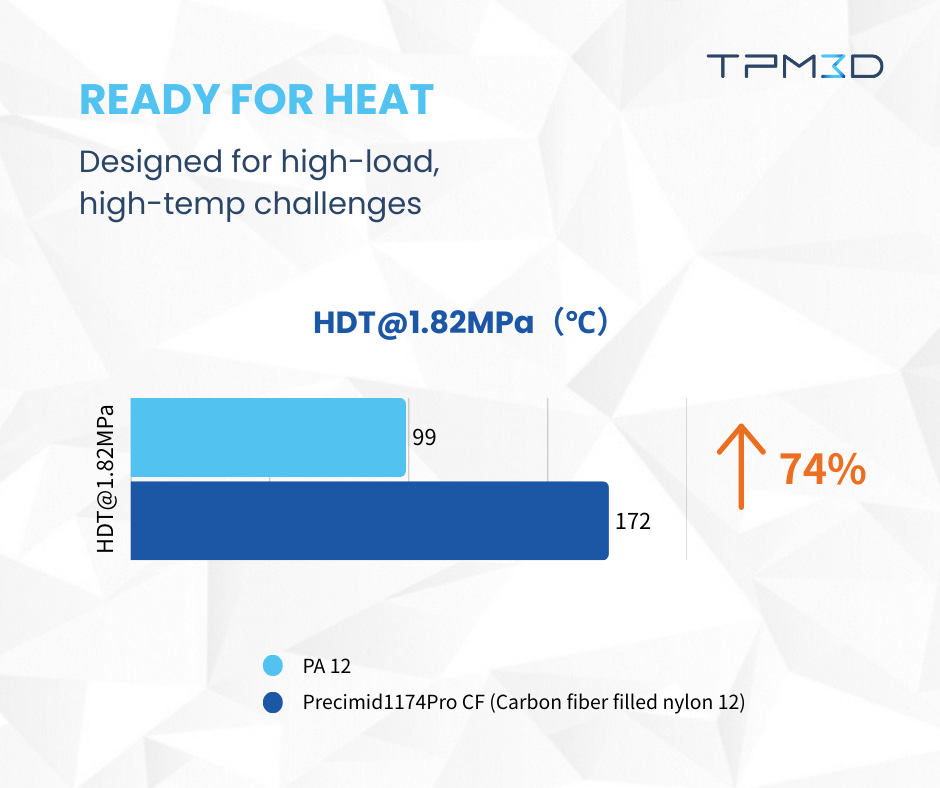

Built to Withstand the Heat

High-temperature environments demand more from your materials. With a heat deflection temperature of 172℃ (HDT@1.82MPa)—a 74% increase over unfilled PA12—Precimid1174Pro CF is up to the task. It’s already being used in parts like automotive intake manifolds, where both heat resistance and mechanical stability are mission-critical.

Strong Yet Lightweight

Despite its reinforced performance, the material remains impressively light at just 1.09 g/cm³—roughly a third the density of aluminum. This makes it a strong candidate for weight-sensitive parts in UAVs, automotive components, and robotic systems, where cutting weight translates into better efficiency, range, and agility.

More Than Just Strength

Thanks to its carbon fiber content, Precimid1174Pro CF offers added benefits including improved wear resistance and anti-static properties—making it suitable for applications like electronic handling tools, robotic end-effectors, and industrial jigs and fixtures where ESD safety and surface durability matter. Its dimensional stability under load also makes it reliable for tight-tolerance components, such as drone frames, structural brackets, and mechanical housings, even in dynamic or high-vibration environments.

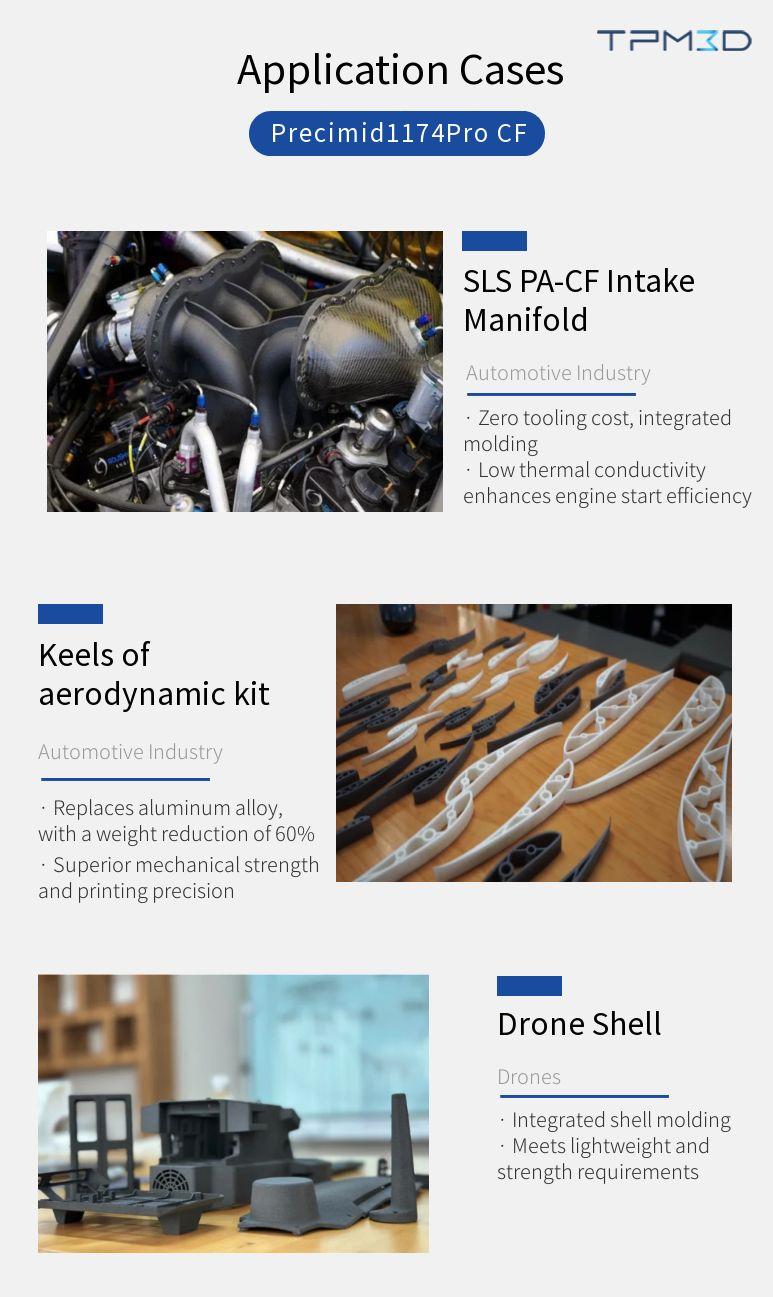

Real-World Applications

From engine compartments to drone casings, Precimid1174Pro CF is already being deployed across multiple demanding sectors:

Automotive:

- 3D-printed intake manifolds: Mold-free, single-piece design with low thermal conductivity

- Aerodynamic kits: Up to 60% lighter than aluminum without sacrificing strength

UAV & Aerospace Drone frame: Lightweight, stiff, and impact-resistant for flight-ready parts

Optimized for SLS 3D Printing

Precimid1174Pro CF is engineered for selective laser sintering with high dimensional accuracy and reliable repeatability. Whether you’re producing functional prototypes or end-use parts, Precimid1174Pro CF allows manufacturers to reduce assembly steps, eliminate tooling costs, and optimize part design for both performance and cost. At TPM3D, our mission is to empower industries through material innovation. With Precimid1174Pro CF, we’re offering a new solution that supports faster development cycles and better part performance—without adding weight.