More than 1 in 4 cars sold worldwide in 2025 is expected to be electric, according to the International Energy Agency (IEA). Global EV sales are projected to surpass 20 million units in 2025, and the market share of electric cars is on track to exceed 40% by 2030 as they become increasingly affordable in more markets.

Against this backdrop of rapid adoption, additive manufacturing is emerging as a key driver of innovation in EV design and production. TPM3D’s selective laser sintering (SLS) 3D printing technology, with its unique advantages, is enabling the industry from R&D through to manufacturing.

Rapid Prototyping: Accelerating R&D

During the EV development stage, fast verification of appearance, assembly, and ergonomics is crucial to project timelines. TPM3D’s SLS 3D printing, which is known for its high precision and quick turnaround, provides an efficient solution for prototyping:

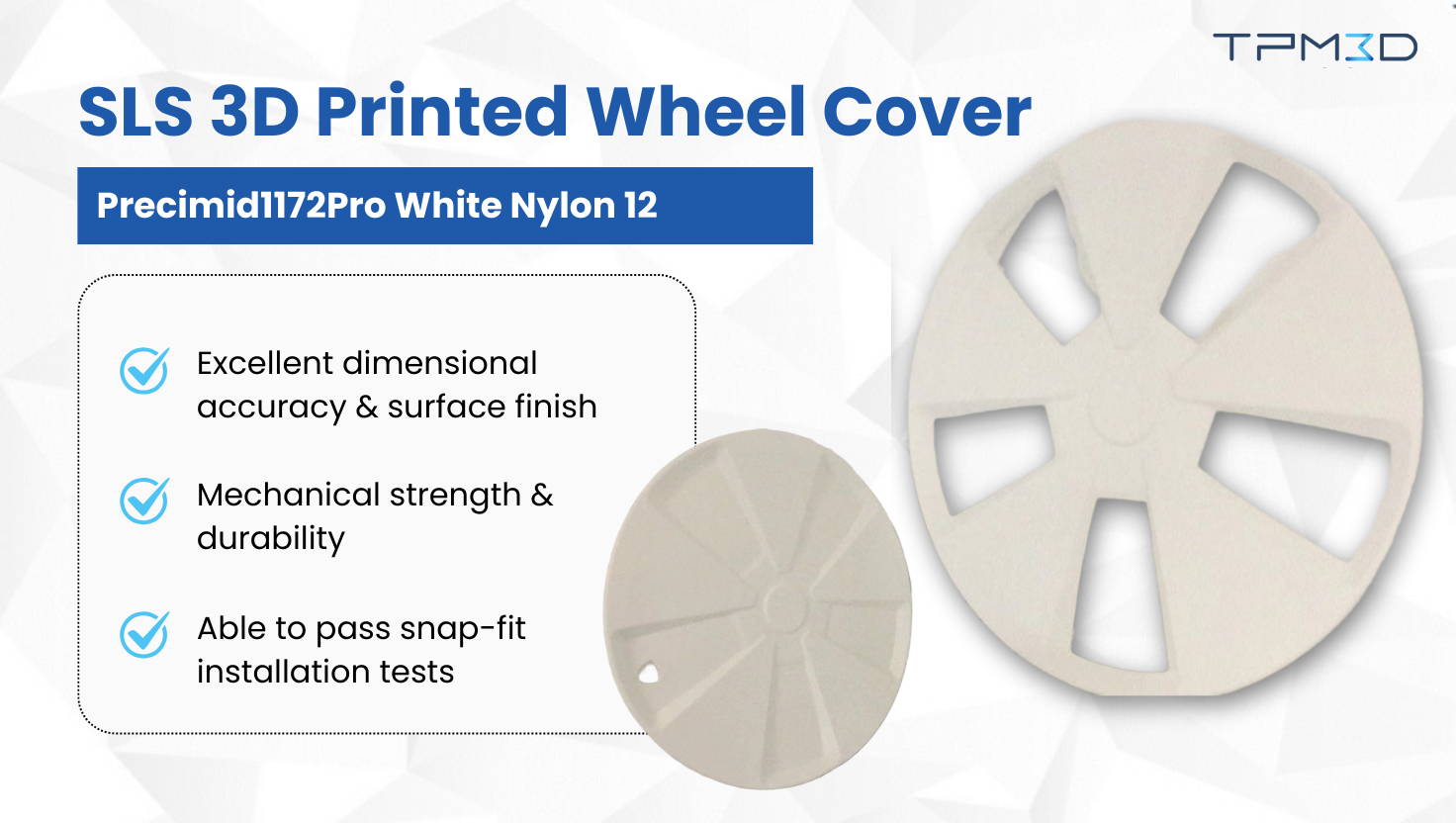

Wheel Cover: Using Precimid1172Pro white nylon 12, TPM3D printed wheel covers with good dimensional accuracy, mechanical strength, and durability. The parts passed snap-fit installation tests and supported finishing processes like painting and plating, simulating final mass-production effects at 1:1 scale.

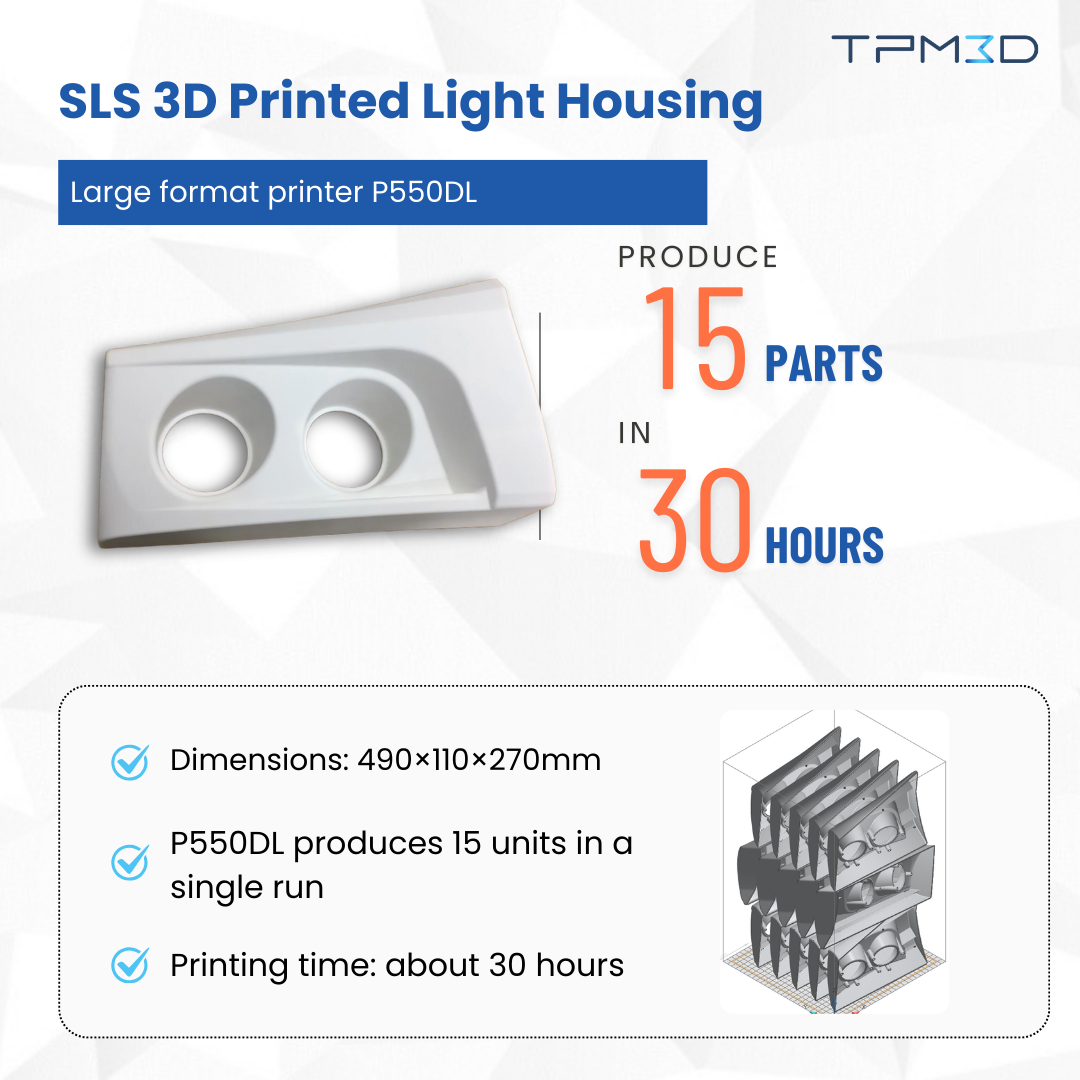

Car Light Housing: With its P550DL system (build size 550×550×850 mm), TPM3D produced 15 car light housings in a single run within 30 hours, reducing cycle time while meeting mechanical performance test requirements.

Small-Batch End-Use Parts: Lightweight, Strong, and Safe

For high-demand applications such as racecars, unmanned vehicles, and specialty fleets, TPM3D’s SLS technology delivers both design flexibility and performance gains.

Beijing Institute of Technology “Triple Crown” Racecar: Student teams used TPM3D to redesign key components, achieving 36.7% weight reduction and UL94-V0 flame retardancy. For example, a battery module bracket traditionally made from fiberglass weighed 300 g. Replacing it with Precimid1171 FR reduced the weight to 190 g while improving fire safety and protecting cells under intense racing conditions.

Tongji University Racecar: In 2020, TPM3D supplied 200 SLS-printed parts across the entire car, from battery boxes and controllers to aerodynamic wings and steering wheels. With V0 flame-retardant nylon 12, the racecar achieved a total weight of just 195 kg, a top speed of 110 km/h, and acceleration from 0–100 km/h in 3.6 seconds.

Technical highlights of selected components:

| Component | Previous Process | SLS Upgrade | Weight/Safety Benefits |

|---|---|---|---|

| Battery Module Frame | Fiberglass board assembly | 3D printed with flame-retardant nylon material | 1 kg lighter, V0 fire rating, precise protection |

| Empty Keel | Wire-cut aluminum & threading | 3D printed with nylon material | 15% weight reduction, high mechanical and fatigue performance |

| Motor Water Jacket | Resin 3D printing | 3D printed with glass-filled nylon material | Lightweight, high precision, excellent mechanical and fatigue resistance |

| Air Duct | Traditional molding | 3D printed | Lighter, complex geometry achievable, high precision |

| Battery Box Front | CNC-milled fiberglass board | 3D printed with flame-retardant nylon material | Reduced weight, safe V0 rating, high mechanical performance |

Dubai Unmanned Police Car: Using a TPM3D S600DL system and Precimid1172Pro GF30 BLK, manufacturer MICROPOLIS printed large structural parts. Compared to metal, production time was cut from 4 days to 2, while weight dropped from 27 kg to just 4 kg—an 82% reduction—boosting efficiency and reducing energy consumption.

Tooling and Fixtures: Lower Costs, Faster Production

At the mass production stage, stable, cost-effective tooling is vital. A leading auto parts supplier adopted TPM3D’s S600DL to produce jigs and fixtures for Hyundai’s global factories. Results were striking:

-

Production Time: Cut from 5.5 days (sand-cast aluminum) to 2.5 days (SLS nylon), a 55% improvement.

-

Cost per Set: Reduced from USD 2,060 to USD 550—a 73% saving.

-

Quality: Yield rates improved significantly, minimizing scrap caused by fixture inaccuracies.

| Process | Production Time | Cost per Set | Yield Rate |

|---|---|---|---|

| Sand-cast Aluminum | 5.5 days | $2,060 | ~75% |

| SLS 3D Printing | 2.5 days | $550 | Higher |

A New Paradigm for EV Manufacturing

From rapid prototype validation to small-batch lightweight and high-safety production, and cost-optimized tooling, TPM3D’s SLS 3D printing demonstrates the potential of additive manufacturing in the EV industry.

With ongoing material upgrades and efficiency improvements, SLS is set to further accelerate EV development toward lighter vehicles, faster production cycles, and higher safety standards.