TPM3D, a leading manufacturer of Selective Laser Sintering (SLS) 3D printing systems, reported solid growth and major technology milestones in 2025, strengthening its position in the global additive manufacturing market.

As polymer 3D printing continued expanding across aerospace, healthcare, robotics, and consumer industries, the company increased shipments, broadened its international footprint, and introduced new industrial SLS solutions designed for both compact and large-format production.

“We remained focused on practical innovation and customer-driven development,” the company said in its annual review. “Our priority is turning advanced SLS technology into reliable, scalable production tools.”

Global Business Expansion Across Key Markets

TPM3D recorded steady shipment growth in 2025, supported by strong domestic demand and expanding overseas partnerships.

In China, the company served customers across the country, working with universities, service bureaus, aerospace suppliers, automotive manufacturers, medical institutions, and consumer electronics companies. Collaboration with academic institutions—including Jianghan University—further strengthened industry–academia integration in SLS research and application.

Internationally, TPM3D systems were deployed across North America, South America, Europe, the Middle East, Russia, and Australia. Application areas ranged from unmanned aerial vehicles and robotics to orthotics, prosthetic sockets, and footwear manufacturing.

Two high-profile international collaborations demonstrated the performance advantages of industrial SLS systems:

-

Edser, Spain, integrated TPM3D’s large-format dual-laser SLS solution, increasing overall production efficiency by 45 percent and improving throughput for orthotic manufacturing.

-

MicroPolis Robotics, Dubai, adopted TPM3D’s S600DL system and dedicated materials to manufacture structural components for autonomous police vehicles. The company reduced part weight from 27 kilograms to 4 kilograms and shortened delivery time from one week to two days.

These cases reflect a broader trend: manufacturers are increasingly turning to SLS 3D printing for lightweight, durable, end-use polymer components.

Product Launches and Technology Breakthroughs

Innovation remained central to TPM3D’s 2025 strategy. With more than two decades of SLS development experience and over 90 patents, the company introduced several major upgrades aimed at improving automation, scalability, and production cleanliness.

CF200 + PPS200 Compact Industrial System

At Formnext in Germany, TPM3D launched the CF200 professional SLS 3D printer, paired with the PPS200 powder processing unit. Designed for small and mid-sized enterprises and research institutions, the system delivers automated workflow integration—from printing to powder recovery and mixing—within a footprint of less than one square meter.

The compact configuration lowers the barrier to industrial SLS adoption while maintaining production-grade performance.

X1100 Large-Format SLS Platform

The company also announced key progress in its national-level R&D project, the X1100 large-format SLS system, featuring a build volume of 1100 × 1100 × 400 mm. The meter-scale breakthrough in both X and Y axes expands the feasibility of additive manufacturing for oversized polymer components, supporting industrial applications that require high efficiency and large part dimensions.

PPS V3.0 Powder Processing Station

To address post-processing challenges, TPM3D released the PPS V3.0, an upgraded powder management workstation integrating six core functions. The system is designed to reduce dust exposure, streamline workflows, and improve overall powder reuse efficiency—critical factors for scalable, clean SLS production environments.

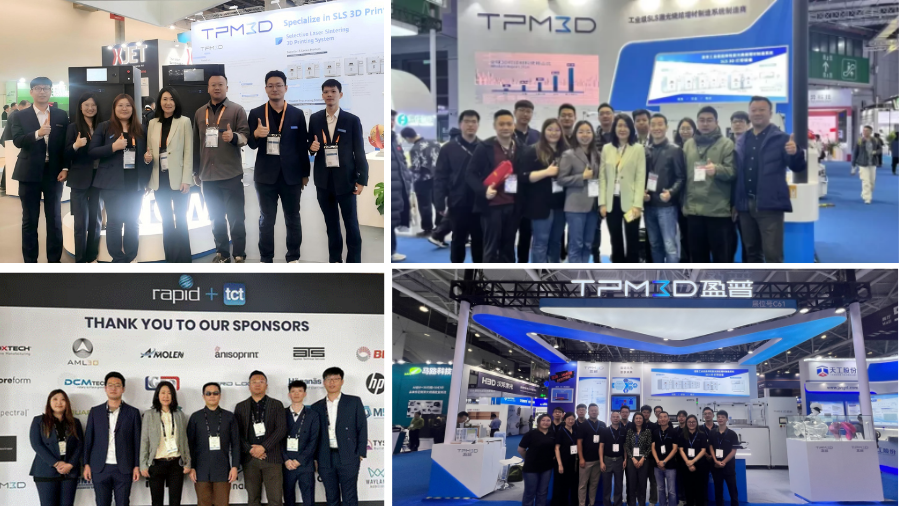

Brand Visibility at Major Global Exhibitions

Throughout 2025, TPM3D expanded its international brand presence by exhibiting at leading additive manufacturing events, including RAPID + TCT (United States), Formnext (Germany), TCT Asia (Shanghai), Formnext Asia (Shenzhen), the China International Supply Chain Expo, and the China Hi-Tech Fair.

Overseas distributors also represented TPM3D at regional events such as AM KOREA and Australia’s AMW exhibition.

The company received recognition as a national-level “Specialized and Sophisticated Little Giant” enterprise in China and was included in the “2025 High-Quality Additive Manufacturing Product List,” reflecting industry acknowledgment of its product performance and technical capabilities.

Operational Expansion and Manufacturing Capacity

In 2025, TPM3D opened its Hefei Chaohu manufacturing facility, strengthening production capacity and improving response times for customers in East China and neighboring regions. The facility has since hosted multiple government and industry delegations, highlighting growing confidence in domestic SLS equipment manufacturing.

Internally, TPM3D conducted cross-departmental training programs covering manufacturing, operations, and after-sales service, aiming to enhance collaboration and technical proficiency across teams.

Outlook for 2026

Looking ahead, TPM3D plans to continue investing in industrial SLS technology development and global market expansion. The company aims to introduce more competitive polymer additive manufacturing solutions while supporting customers transitioning from prototyping to scalable production.

As the global additive manufacturing industry matures, demand for reliable, automated, and large-format polymer 3D printing systems is expected to grow. TPM3D is positioning itself to meet that demand through continued R&D investment and international collaboration.

“Our long-term direction remains clear,” the company said. “Advance SLS technology, improve production efficiency, and deliver dependable solutions for industrial users worldwide.”