SLS 3D printing technology is widely used in industrial and high-precision manufacturing. Most SLS machines are equipped with a single laser, which can limit print size and efficiency. TPM3D’s dual laser SLS 3D printers address these limitations, offering higher productivity, larger build areas, and superior part quality.

Why Dual Laser SLS Printers Are Important

Dual laser SLS 3D printers improve performance in two key ways:

-

Larger Printing Area

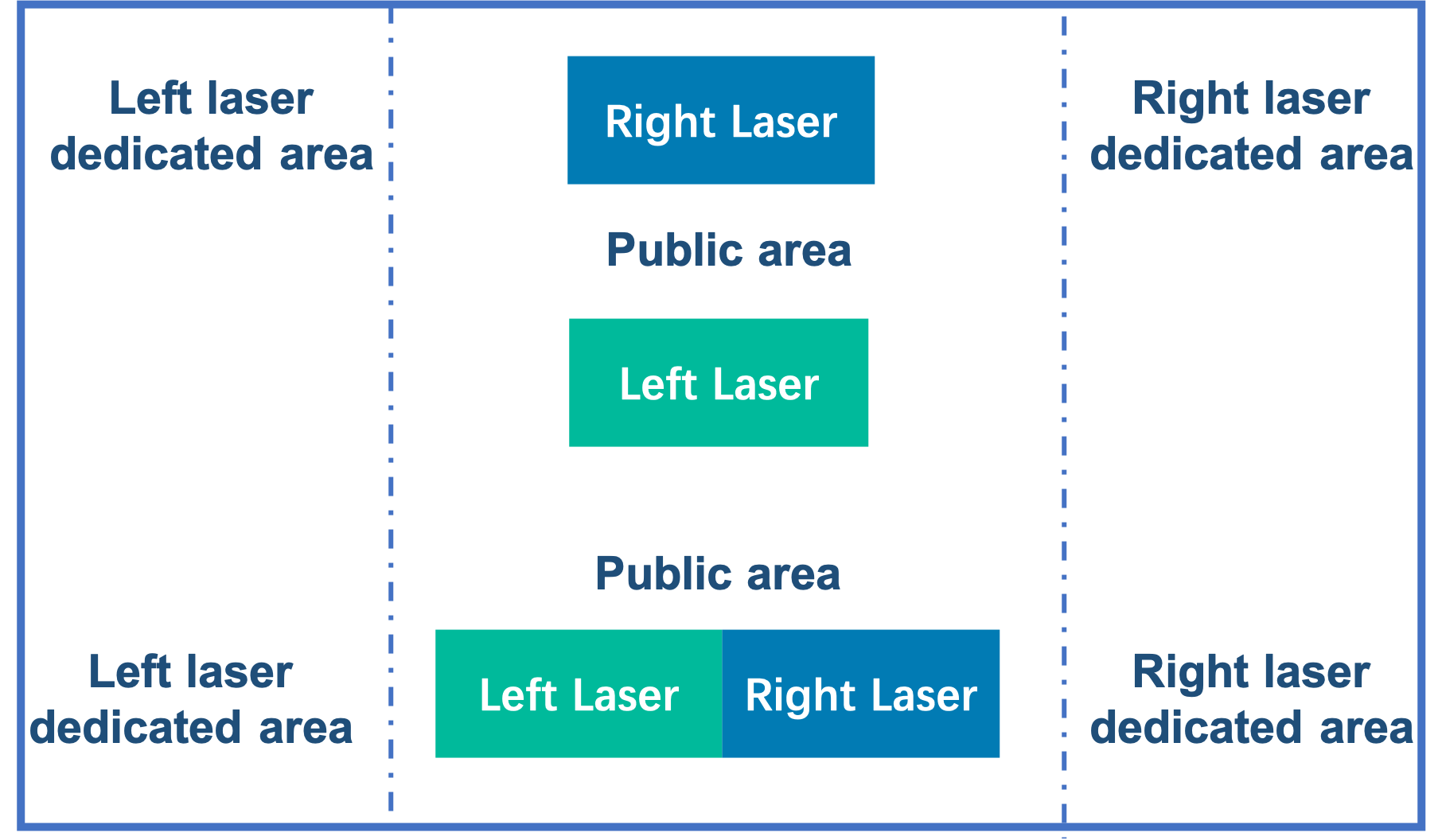

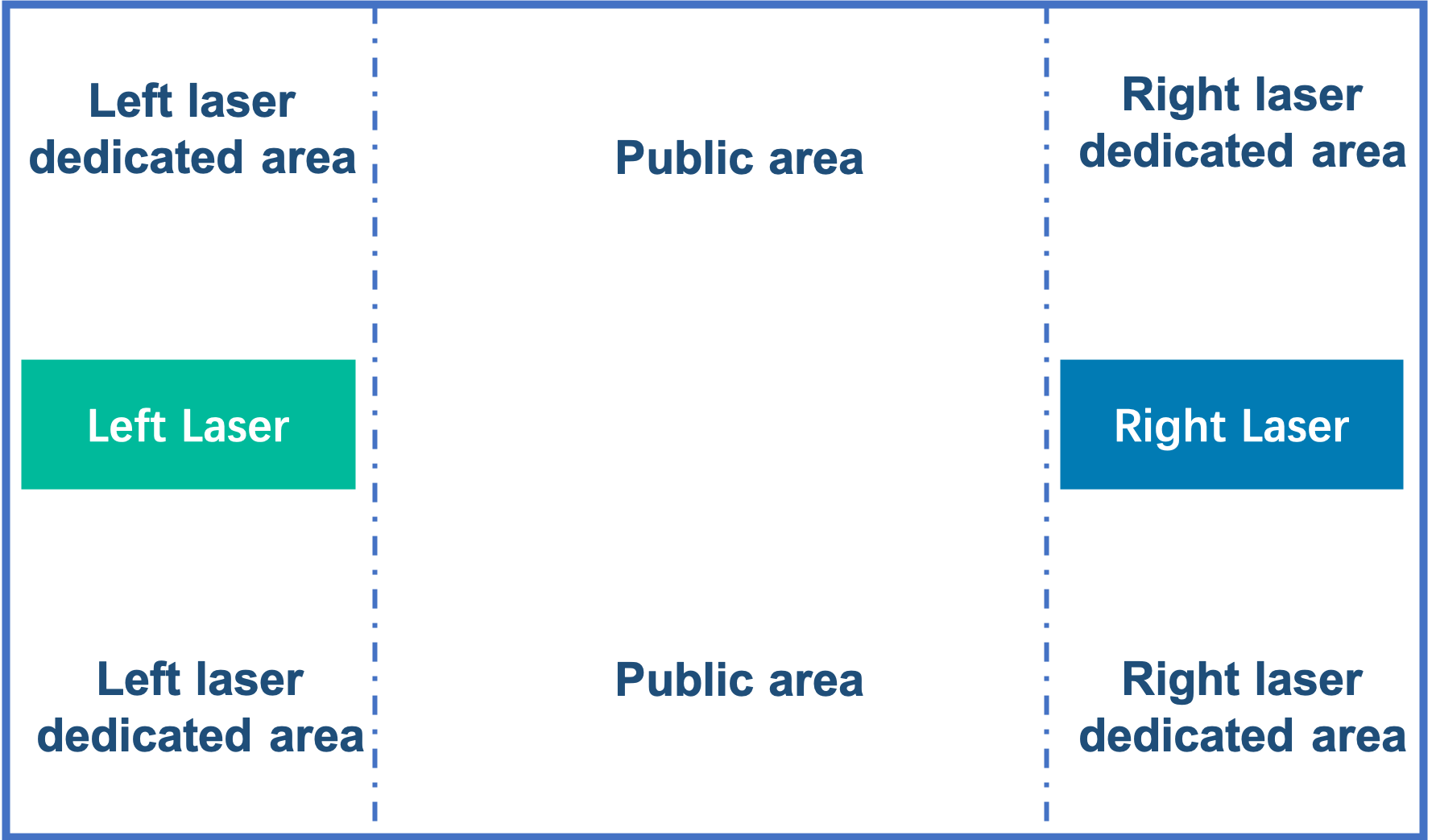

By adding multiple laser systems and scanners, the printing area can be significantly expanded. This allows for the production of larger models. However, in some dual-laser setups, the overlap areas between lasers may create visible seams, potentially affecting surface finish and part strength. -

Improved Forming Efficiency

Dual laser systems can also focus on increasing production speed without necessarily enlarging the printing area. The TPM3D P550DL, for example, features a 300mm laser overlap zone. Using intelligent cooperative scanning, the system automatically coordinates the work of both lasers based on the size and distribution of parts. This ensures:

-

Faster printing speeds

-

Optimized layer splicing to avoid repetitive seam positions

-

Enhanced surface quality and structural strength

Key Advantages of TPM3D Dual Laser SLS 3D Printers

-

Large Build Volume: Print bigger parts in a single job, reducing the need for assembly.

-

High Forming Efficiency: Dual lasers work cooperatively to maximize production speed.

-

Optimized Splicing Areas: Intelligent scanning avoids repetitive seam positions, improving part strength and appearance.

-

High-Quality Output: Enhanced surface finish and structural integrity for industrial-grade applications.

Conclusion

TPM3D dual laser SLS 3D printers combine large build volumes, high efficiency, and optimized scanning strategies. They are ideal for industries requiring large-scale, high-precision, and high-quality additive manufacturing solutions.