While 3D printing is known for handling complex geometries, printing highly intricate models pushes the limits of precision, detail, and consistency. Today, we present a particularly challenging project: a complex Rubik’s Cube.

A High-Difficulty Challenge

This Rubik’s Cube consists of 27 interlocking components, each featuring:

-

Complex surface textures

-

Fine structural details

-

Hollow and lattice features

-

Integrated printing requirements

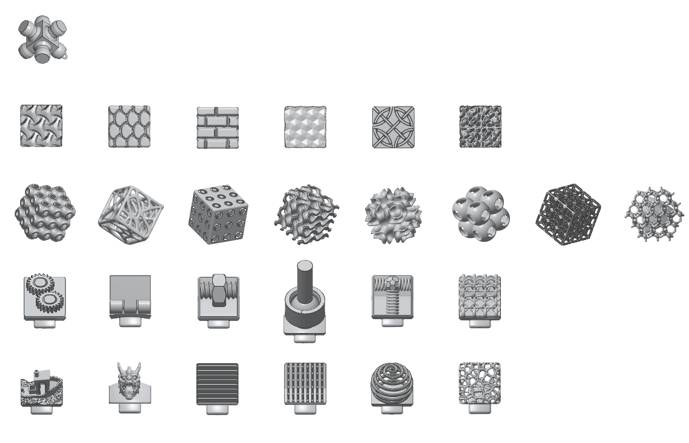

27 components of the Rubik’s Cube

Each component had unique characteristics, demanding consistent accuracy to ensure smooth rotation and flawless assembly. The model tested the printing device’s performance across multiple aspects, including surface quality, mechanical strength, and dimensional precision.

Precision Requirements for Each Component

-

Core Block: Required excellent mechanical strength and a smooth, wear-resistant surface for long-term rotation.

-

Docking Block: Needed high strength, precise concave and convex textures, and smooth assembly.

-

Corner Block: Tested the printer’s ability to handle small hollow and lattice structures, as well as thorough powder removal.

-

Edge Block: Focused on integral assembly and fine structure printing, verifying material durability and mechanical robustness.

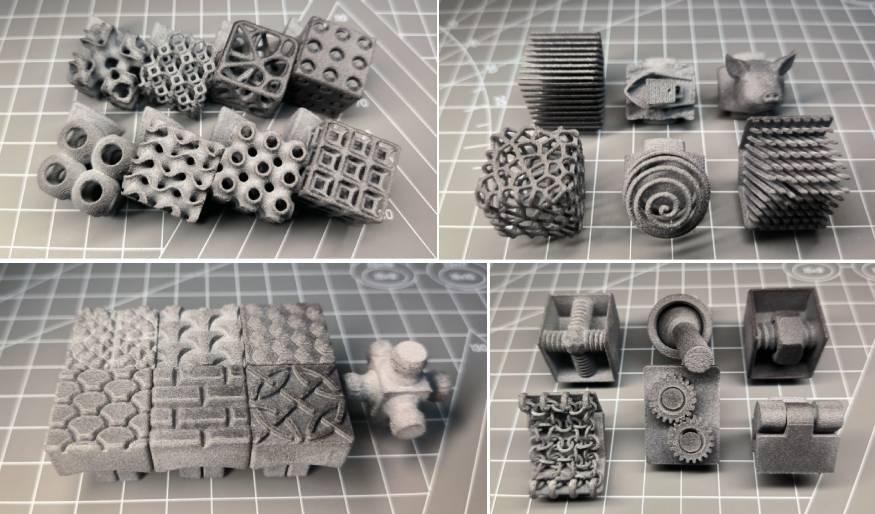

3D printed components of the Rubik’s Cube

Printing Material and Equipment

For this project, we selected TPM3D Precimid1172Pro BLK (PA12), a versatile material offering:

-

Stable color and excellent surface finish

-

Wear resistance and durability

-

High cost-efficiency, with new powder usage as low as 20%

The printing was performed on the TPM3D P360, with a layer thickness of 0.1 mm, ensuring high detail fidelity and dimensional accuracy.

The TPM3D P360 + PPS clean production system efficiently handled post-processing, including powder cleaning, dust collection, and automatic powder recycling, reducing labor while maintaining a safe and clean production environment.

Post-Processing and Final Results

After powder cleaning and sandblasting, all 27 components exhibited exceptional precision, smooth surfaces, and consistent assembly clearance. Each block could be assembled seamlessly, enabling fluid rotation.

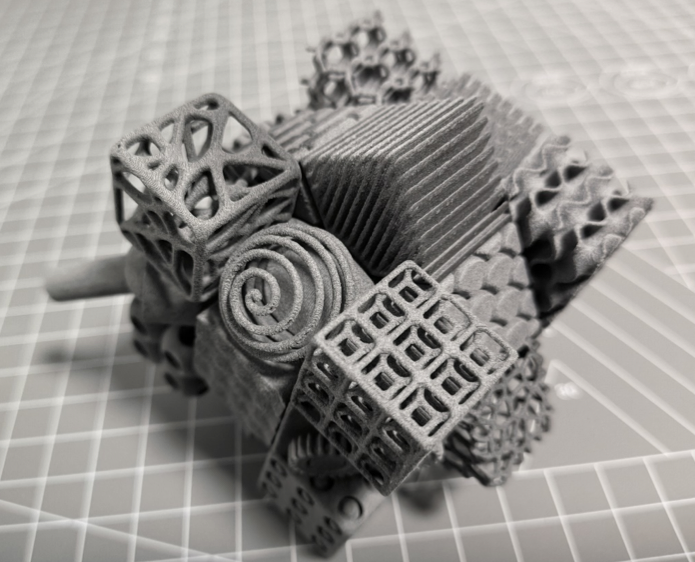

SLS 3D printed Rubik’s Cube before post-processing treatment

For an even higher-quality finish, chemical vapor smoothing was applied, resulting in:

-

A bright, polished surface

-

Improved rotation smoothness

-

Enhanced waterproofing and durability

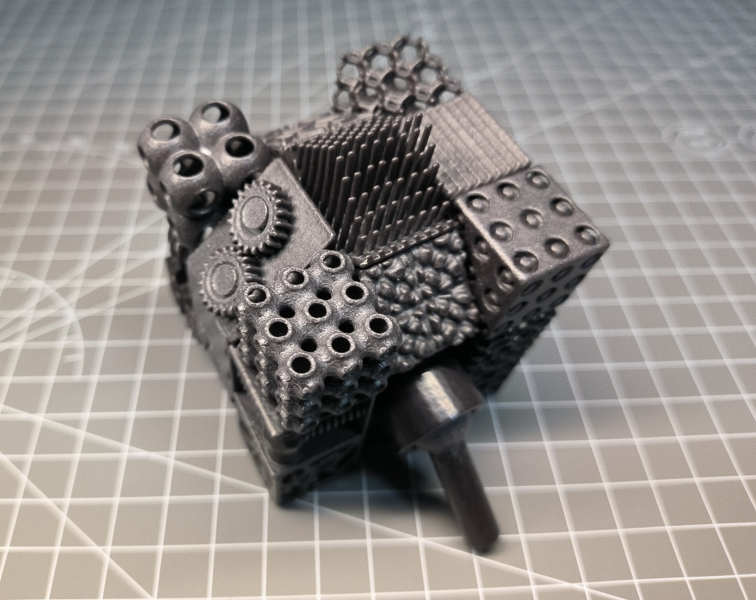

SLS 3D printed Rubik’s Cube after chemical vapor smoothing treatment

The final Rubik’s Cube demonstrates the power of SLS printing for producing highly intricate, mechanically functional models that maintain both aesthetic appeal and practical performance.