Formula Student China (FSC) is a premier platform for training and selecting outstanding automotive talents. It features three events: Formula Student Combustion China (FSC), Formula Student Electric China (FSEC), and Formula Student Autonomous China (FSAC).

As China’s leading manufacturer of SLS 3D printing equipment, TPM3D has sponsored the competition for three consecutive years, providing young engineers with opportunities to explore and apply advanced 3D printing technology.

In 2021, TPM3D specifically sponsored driverless teams from Beijing Institute of Technology (BIT) and Tongji University Racing Team. Below is an overview of how SLS 3D printing was applied in these high-performance racing cars.

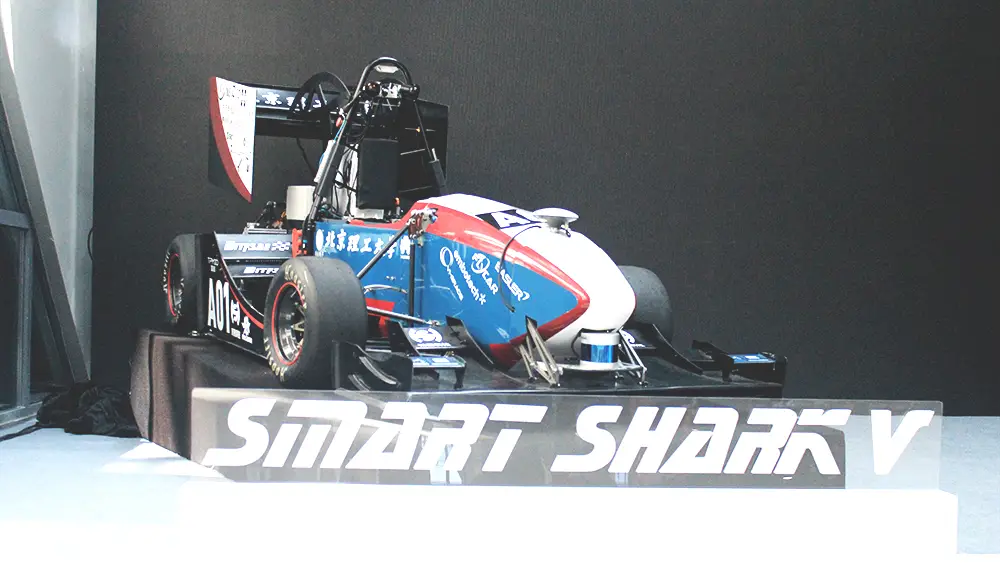

Beijing Institute of Technology Driverless Racing Team

Founded in 2007, the BIT Driverless Racing Team (BITFSD) independently designed and manufactured the world’s first driverless college student formula racing car in 2016. The team went on to win championships in 2017, 2018, and 2020, making it the only “triple champion” in Chinese university formula racing.

In 2021, TPM3D provided BITFSD with SLS 3D printed components across five categories, including:

-

Low-voltage box shell

-

High-voltage box shell

-

Energy meter shell

-

Flame-retardant battery module frame

-

Industrial computer shell

These components were integrated into the electronic control system, energy system, braking system, and body of the racing car. The lightweight 3D printed parts significantly improved the car’s performance, efficiency, and safety.

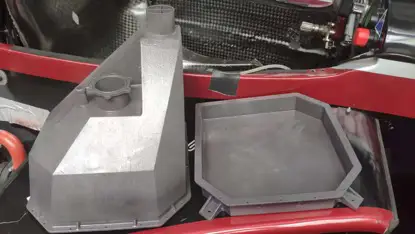

Lightweight Battery Modules: Improved Safety and Performance

The battery module is the energy core of the racing car. Previously, BITFSD manufactured the module frame using glass fiber board bonding. In 2021, the team switched to TPM3D’s Precimid1171 FR (PA12) material—a flame-retardant polymer certified to UL94 V-0 standards.

This material not only provides excellent surface finish and resistance characteristics but also reduces the weight of the battery module by nearly 37%, contributing to faster acceleration and better energy efficiency.

Energy Meter Shells: Strength and Thermal Stability

Each racing car includes an energy meter to ensure that the power remains below 80 kW for safety. BITFSD printed the energy meter shell using TPM3D’s Precimid1172Pro GF30 (PA12) material. The addition of 30% glass fiber enhances mechanical strength, wear resistance, and impact resistance.

The shell also exhibits a thermal deformation temperature of 184°C at 0.45 MPa, ensuring reliable operation under high thermal loads—critical for maintaining safe energy management in the racing car.

Industrial Computer and Camera Shells: Lightweight Protection

TPM3D also supplied Precimid1172Pro (PA12) material for the industrial computer and camera shells. These components combine light weight, good toughness, and comprehensive mechanical performance, protecting sensitive electronics while minimizing additional mass. The reduced weight contributes to both improved vehicle handling and increased safety, allowing the driverless car to perform at its best.

Conclusion: Racing Toward Success

The collaboration between TPM3D and BITFSD demonstrates the transformative potential of SLS 3D printing in driverless racing. By reducing weight, improving mechanical performance, and providing flame-retardant and thermally stable components, 3D printing technology helps student teams push the limits of performance and safety.