The combination of automobiles and 3D printing is no longer limited to concept cars. Today, 3D printing technology runs throughout the automotive industry—from vehicle research and development (R&D) to trial production, production line fixtures and jigs, customized modifications, and even mass production.

Dongfeng Motor Group, one of China’s leading automotive manufacturers, has been at the forefront of adopting selective laser sintering (SLS) 3D printing technology to improve efficiency, reduce costs, and accelerate development cycles.

Understanding Automotive Components and Materials

A modern car consists of thousands of components—typically between 10,000 and 20,000 parts—divided into major systems such as the engine, chassis, body, and electrical equipment. These components are made from a variety of materials, broadly classified as metals and non-metals.

Non-metallic parts include interior trim, exterior trim, seals, and tires, which account for a significant portion of the vehicle’s weight and functionality.

During the design and R&D stage, if the goal is primarily size and assembly verification, nearly all non-precision parts can be produced using 3D printing. This allows engineers to validate fit, alignment, and overall design without relying on traditional manufacturing methods.

However, functional verification, small-batch production, and final-use parts are more restricted due to the current limitations of 3D printing materials and processes.

Nonetheless, the rapid advancement of 3D printing technology has significantly expanded its applications in automotive development, enabling new possibilities for prototyping, production support, and end-use components.

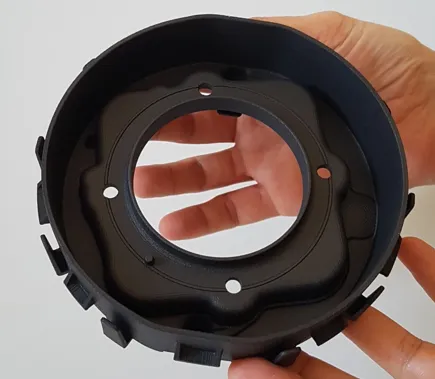

Carbon fiber-reinforced airbag housing, 3D-printed by Joyson Safety Systems using SLS technology

Dongfeng Motor Group’s Application of SLS 3D Printing

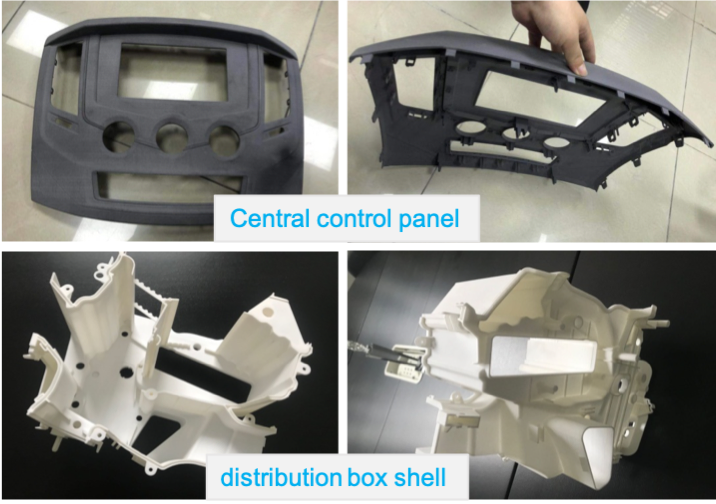

In the automotive sector, Dongfeng Motor Group has adopted SLS 3D printing technology to manufacture prototype parts during the trial production of new vehicles.

For example, the central control panel of a prototype vehicle is printed using TPM3D’s Precimid1172Pro GF30 BLK, a 30% glass fiber reinforced nylon 12 material that offers excellent strength and impact resistance. Similarly, distribution box shells are printed with Precimid1172Pro, a general nylon 12 material that combines good mechanical performance with smooth surface quality.

By using SLS 3D printing, Dongfeng Motor Group eliminates the need for traditional injection molding or CNC machining for these plastic components. This simplifies the prototype manufacturing process, reduces outsourcing costs, and mitigates the risk of intellectual property leakage from prototype models.

Wider Applications Across the Automotive Industry

Other automotive manufacturers, such as GAC Group, have also explored SLS technology for a wider range of applications. SLS-printed parts are now used for interior and exterior trims, heat exchange systems, powertrain components, chassis elements, and more. The technology supports multiple verification types, including appearance, structural integrity, assembly fit, and ergonomic testing, across dozens of component categories.

Previously, the subcontracting process for prototyping required multiple steps—demand submission, cost approval, vendor inquiries, delivery, receipt, and acceptance—taking two to three weeks. With in-house SLS 3D printing, this workflow has been streamlined to just four steps: demand submission, printing, receipt, and acceptance. Verification can now begin in as little as four days, all within the company, drastically improving efficiency.

The Future of 3D Printing in Automotive Production

The examples of Dongfeng Motor Group and GAC Group demonstrate how 3D printing is no longer just a tool for concept cars but a critical enabler of modern automotive R&D, trial production, and even customized production. As the technology continues to evolve, the range of parts and applications suitable for 3D printing will expand, further integrating additive manufacturing into the automotive industry’s full lifecycle—from design and prototyping to production and final delivery.

Conclusion: Efficiency, Cost Reduction, and Innovation

By adopting SLS 3D printing technology, Dongfeng Motor Group has accelerated its R&D cycle, reduced costs, simplified manufacturing, and increased control over intellectual property. As technological advancements continue, the role of 3D printing in the automotive industry is expected to grow proportionally, opening new opportunities for innovation and efficiency across the sector.