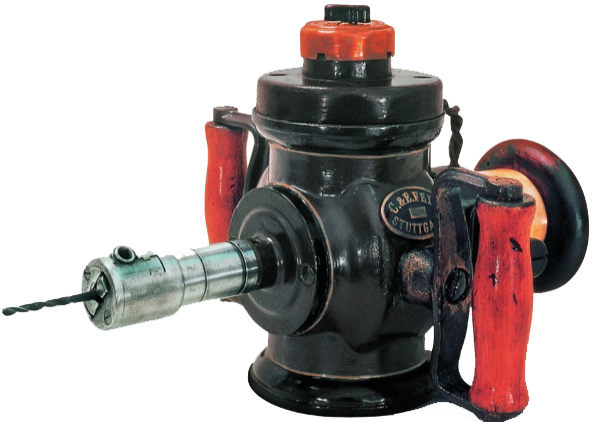

Efficiency improvement has always been one of the main drivers of technological progress. In 1895, Germany-based FEIN developed the world’s first DC hand-held electric drill, marking a turning point in modern manufacturing tools. Early drill casings were made from aluminum alloy, which provided durability but limited weight reduction. Over time, thermoplastics gradually replaced metals, making power tools lighter and easier to use.

As the industry evolved, so too did user expectations. Today’s consumers demand power tools that are not only efficient, lightweight, and ergonomic, but also stylish and safe. Meeting these requirements has pushed manufacturers to adopt faster, more flexible methods of research and development. This is where Selective Laser Sintering (SLS) 3D printing technology comes in.

Why SLS Technology Meets the Needs of Modern Toolmakers

In the early stages of product design, manufacturers face constant trade-offs between cost, precision, and development speed. Traditional CNC machining remains accurate but requires complex programming and is time-consuming for intricate geometries.

By contrast, SLS 3D printing is insensitive to design complexity. Once a digital 3D model is ready, the part can be produced directly, eliminating tooling requirements and cutting weeks off the development timeline.

Compared with injection molding, SLS offers another set of advantages. Injection molding requires expensive dies, often making it uneconomical in the early stages of R&D.

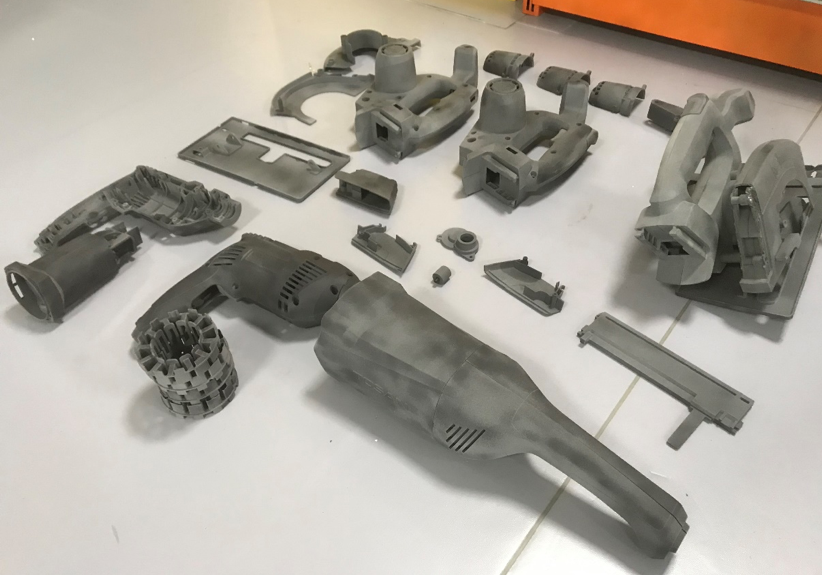

With SLS, manufacturers can obtain high-precision prototypes that closely mimic injection-molded parts in strength and durability, but without investing in tooling. These printed components can be immediately assembled with other parts for real-world testing, accelerating iteration.

When comparing SLS with other additive manufacturing methods such as FDM and SLA, the benefits become even clearer. While FDM and SLA are accessible and suitable for concept models, they fall short in efficiency, cost, and durability for functional prototypes.

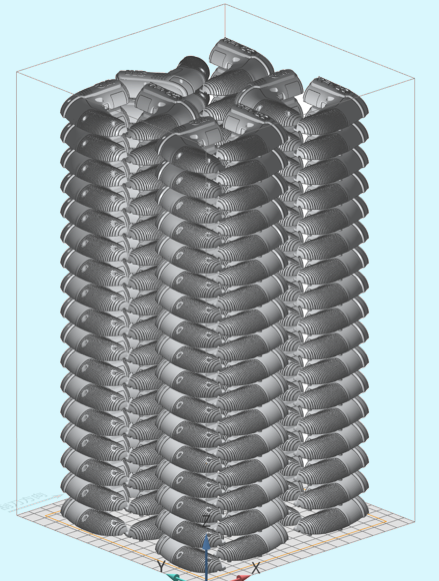

SLS, by contrast, supports stacked builds, enabling rapid production of many parts in a single job. It also works with advanced composite polymer materials—such as nylon reinforced with glass beads or aluminum powder—making it well-suited for batch production of power tool prototypes.

TPM3D’s Role in Power Tool Innovation

As a professional manufacturer of industrial SLS equipment, TPM3D has established a strong presence in the power tools sector. Global suppliers such as TTI and CROWN, both well-known brands in home decoration and construction tools, have adopted TPM3D’s systems in their R&D workflows.

TPM3D is not only a hardware supplier but also an active materials developer, continuously expanding the possibilities for electric tool applications. Two standout materials currently in use are:

-

Precimid1172Pro GF30 BLK

A gray-black, glass-fiber reinforced nylon. It offers high heat resistance, bending strength, and impact strength, making it ideal for the demanding conditions of power tools—such as vibration, friction, and heat buildup. With excellent accuracy and durability, parts produced from this material are capable of long-term use. -

Precimid1171Pro AF40

A nylon-aluminum composite consisting of white PA12 powder blended with 40% gray aluminum powder. This material not only provides heat and impact resistance but also combines high hardness and machinability. Its surface carries a metallic texture, giving prototypes an appearance similar to final commercial products, which is especially valuable in design validation and marketing.

Transforming R&D Cycles

In practice, SLS 3D printing empowers power tool designers with a new level of agility. By enabling the rapid production of functional prototypes at lower cost, SLS makes it possible to run multiple iterations in quick succession. Components can undergo functional verification, fit checks, and durability testing within hours of design completion.

With TPM3D’s technology, the modification–manufacturing–retesting loop can often be completed in just 48 hours. This significantly shortens the product development cycle, allowing companies to detect design flaws earlier, reduce production risks, and bring innovative tools to market faster.

Beyond speed, cost savings are also substantial. Eliminating mold costs and minimizing machining steps reduces overall expenses, even as companies benefit from higher R&D throughput.

Ultimately, SLS technology allows manufacturers to achieve both cost reduction and efficiency improvement, aligning with modern industry goals of lean development and rapid market response.

Looking Ahead

From the invention of the first DC hand drill to today’s sophisticated, multifunctional power tools, the industry has always evolved in pursuit of efficiency and user satisfaction.

Now, with SLS 3D printing, toolmakers have an advanced technology that not only meets today’s demands but also lays the groundwork for the future of rapid, flexible, and sustainable product development.

With industrial leaders like TPM3D providing both equipment and materials expertise, SLS is poised to become a cornerstone technology in the continued evolution of the electric tools industry.