The Eyewear Revolution: Embracing 3D-Printed Glasses Frames

The eyewear industry, long defined by mass production and standardized sizes, is undergoing a profound transformation. For centuries, frames were crafted through subtractive methods like milling or injection molding—processes that, while effective, often limited design complexity and led to significant material waste.

Today, a new paradigm has emerged, one that places personalization, sustainability, and unprecedented design freedom at the forefront. This is the era of additive manufacturing, and 3D-printed glasses frames are revolutionizing how we see the world and how the world sees us.

This technology is not just a novelty; it’s a fundamental shift that empowers consumers, designers, and opticians alike. It promises a future where eyewear is no longer a one-size-fits-all accessory but a perfectly tailored extension of one’s personal style and physical form. From hyper-customized fits that eliminate discomfort to intricate designs impossible to create with traditional methods, 3D printing is reshaping the entire eyewear ecosystem.

What Are 3D-Printed Glasses Frames?

At its core, a 3D-printed glasses frame is created through additive manufacturing. Unlike traditional methods that cut away from a solid block of material (subtractive), 3D printing builds the frame layer by layer from a digital design file. A 3D model of the glasses is sliced into hundreds or thousands of thin horizontal layers, and a printer deposits, fuses, or cures material to construct the object from the ground up. This process allows for the creation of lightweight, durable, and highly complex structures directly from a computer-aided design (CAD) file.

Why 3D Printing is Redefining Eyewear

The impact of 3D printing on the eyewear industry is multi-faceted. It shatters the constraints of traditional manufacturing, where high costs for molds and tooling dictate design choices and production volumes. Additive manufacturing enables rapid prototyping, on-demand production, and small-batch runs without the prohibitive upfront investment. This agility allows brands to innovate faster and cater to niche markets. For the consumer, it unlocks a level of personalization previously reserved for bespoke luxury goods, making custom-fit, uniquely designed eyewear more accessible than ever before.

Unlocking Unprecedented Personalization and Fit

The most significant advantage of 3D-printed eyewear is its ability to deliver a truly personalized product. The limitations of standard small, medium, and large sizes are replaced by a data-driven approach that tailors frames to the unique topography of an individual’s face.

The Perfect Fit: Tailor-Made Eyewear for Every Face

Using 3D scanning technology, an optician or even a smartphone app can capture precise measurements of a person’s facial features—including pupillary distance, nose bridge width, temple length, and head width. This data is used to create a digital model that informs the production of a frame designed to fit perfectly. The result is eyewear that doesn’t slip, pinch, or cause discomfort, offering superior comfort and optimal lens positioning for better visual acuity.

Beyond Standard Sizes: Adjustable Geometry and Unique Shapes

3D printing moves beyond simple fit adjustments. It allows for the creation of frames with parametric or generative designs, where algorithms help generate unique, aesthetically pleasing shapes optimized for strength and weight. This means consumers are no longer limited to off-the-shelf styles. They can co-create frames with intricate lattice structures, custom textures, or asymmetrical designs that are a true expression of their personality, all while ensuring the frame is structurally sound and perfectly balanced.

The Additive Advantage: How 3D Printing Transforms Eyewear Manufacturing

The shift from traditional to additive manufacturing represents a fundamental change in the entire production workflow, offering efficiencies and capabilities that were previously unattainable.

From Digital Design to Physical Frame: The Workflow

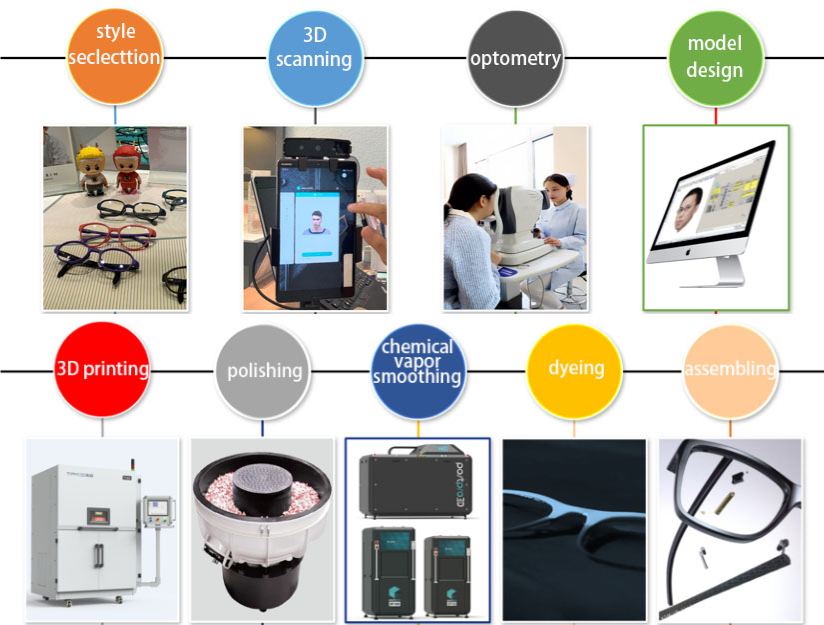

The journey of a 3D-printed frame begins as a digital file. Designers use CAD software to create the initial concept. This design can then be customized using a customer’s 3D facial scan data. Once finalized, the digital model is sent to a 3D printer. The printer builds the frame layer by layer, a process that can take several hours. After printing, the frame undergoes post-processing steps to achieve the desired finish before the lenses are fitted and final assembly is completed.

Key 3D Printing Technologies for Eyewear

While several 3D printing technologies exist, Selective Laser Sintering (SLS) has become the industry standard for producing high-quality, end-use eyewear frames. SLS uses a high-powered laser to fuse together small particles of polymer powder, typically a nylon variant.

The key advantage of SLS is that the surrounding unfused powder supports the object during printing, eliminating the need for support structures that must be removed later. This allows for the creation of highly complex, “unmoldable” geometries and even print-in-place hinges, streamlining the assembly process.

Solutions from innovators like TPM3D offer advanced SLS systems specifically optimized for producing durable, detailed, and consistent eyewear components at scale.

Materials That Matter: Performance, and Aesthetics

The most common material for 3D-printed frames is Polyamide 12 (PA12), a type of nylon known for its exceptional properties. It is incredibly strong yet flexible, lightweight, and resistant to chemicals and UV radiation. This combination makes it ideal for everyday wear, as the frames can withstand drops and bending without breaking.

PA12 is also biocompatible, making it suitable for prolonged skin contact. These materials can be dyed in a vast spectrum of colors, allowing for rich, vibrant aesthetic choices.

Post-Processing for a Premium Finish

Raw 3D prints often have a slightly grainy surface texture. To achieve a premium, retail-ready look and feel, frames undergo various post-processing steps. These can include tumbling with ceramic chips to smooth the surface, vapor smoothing to create a glossy finish, or dyeing to impart color. Protective coatings can also be applied to enhance UV resistance and make the frames easier to clean, ensuring the final product rivals the quality of traditionally manufactured eyewear.

Quality Checks and Assembly Features

Throughout the manufacturing process, strict quality control is essential. Digital checks ensure the design file is error-free, while physical inspections after printing and post-processing verify dimensional accuracy and structural integrity. Advanced design techniques allow for the integration of features like snap-fit channels for lenses and robust hinge mechanisms, simplifying the final assembly and ensuring the long-term durability of the glasses.

Sustainability Through Additive Manufacturing

Beyond personalization and design freedom, 3D printing offers a significantly more sustainable approach to eyewear production, addressing key environmental concerns within the fashion and manufacturing industries.

Reducing Waste: The Efficiency of 3D Manufacturing Systems

Traditional eyewear manufacturing, particularly with acetate, is a subtractive process that can be incredibly wasteful. It has been noted that these techniques can waste up to 70% of the material used to produce a single pair of frames. In contrast, 3D printing is an additive process that uses only the material needed to create the part. The unused powder in an SLS printer can often be recycled and reused in subsequent print jobs, drastically reducing material waste.

Eco-Friendly Materials: Bio-plastics, and Recycled Materials

The material science behind 3D printing is rapidly evolving, with a growing focus on sustainability. Manufacturers are developing bio-based polyamides derived from renewable resources like castor oil, reducing the reliance on fossil fuels. Furthermore, research is underway to improve the recyclability of printing powders and even create filaments from recycled plastics, paving the way for a more circular economy in the eyewear sector.

Manufacturing Sustainability: A Greener Supply Chain

On-demand production eliminates the need for large inventories, reducing the waste associated with unsold stock. Furthermore, localized manufacturing becomes more viable, allowing frames to be printed closer to the point of sale. This shortens the supply chain, reduces transportation emissions, and contributes to a smaller overall environmental footprint. A life cycle analysis found that the carbon footprint of customized, 3D printed eyewear is around 58% lower compared to conventionally manufactured alternatives.

The Functional Edge: Beyond Style, and Comfort

While style and a perfect fit are primary drivers, the functional benefits of 3D-printed frames provide a distinct performance advantage for the wearer.

Lightweight and Durable Frames for Everyday Wear

The materials used in 3D printing, like PA12, offer a superior strength-to-weight ratio. This results in frames that are noticeably lighter than many traditional acetate or metal options, enhancing comfort for all-day wear. Despite being lightweight, they are remarkably resilient and flexible, capable of absorbing impacts that would shatter or permanently deform other materials.

Hypoallergenic Materials for Sensitive Skin

Many people experience skin irritation or allergic reactions to the metals (like nickel) or plasticizers found in conventional glasses frames. The high-grade polymers used in SLS 3D printing are typically hypoallergenic and biocompatible, providing a safe and comfortable solution for individuals with sensitive skin.

The Future is Now: Paving the Way for Smart Eyewear

The design freedom of 3D printing is a critical enabler for the next generation of smart eyewear. The technology allows for the seamless integration of complex electronics, sensors, and batteries directly into the frame’s structure. Custom channels for wiring or bespoke cavities for components can be designed into the frame from the start, accelerating the development of augmented reality glasses and other wearable tech in a more discreet and ergonomic form factor.

The Optician’s Integral Role in the 3D-Printed Eyewear Ecosystem

As eyewear production becomes more personalized and digital, the role of the skilled optician becomes more crucial than ever. They are the essential human link between advanced technology and the end-user, ensuring both optimal vision and a perfect product.

Integrating 3D Scanning into Optical Practices

Forward-thinking optical shops are incorporating 3D facial scanners into their practices. This technology allows them to capture a customer’s precise biometric data in minutes. This data-driven approach elevates the fitting process from an approximation to an exact science, providing the foundation for creating truly custom-made frames.

Expert Consultation for Custom Frames, and Lens Types

While technology provides the data, the optician provides the expertise. They consult with clients to understand their lifestyle, aesthetic preferences, and visual needs. They guide them through the process of choosing a frame style, material, and color, and most importantly, they recommend the ideal lens type and coatings to ensure superior optical performance.

Ensuring the Perfect Fit and Optical Performance

After the 3D-printed frame is produced, the optician performs the final fitting and adjustment. They ensure the frame sits correctly on the face, that the optical center of the lenses is perfectly aligned with the pupils, and that the customer is completely satisfied with the comfort and vision. This final, hands-on step is vital for realizing the full potential of custom eyewear.

Addressing Common Questions, and Concerns

As with any innovative technology, consumers and industry professionals have valid questions about the practicality, cost, and durability of 3D-printed frames.

Durability and Longevity of 3D-Printed Frames

A common misconception is that “plastic” 3D-printed frames are flimsy. However, frames made with industrial-grade SLS printers from materials like PA12 are engineered for toughness and flexibility. They are resistant to impact and environmental factors, often proving more durable than brittle acetate frames. With proper care, they are built to last for many years.

Cost-Benefit Analysis: 3D Printing vs. Injection Molding

For mass-produced, identical frames, injection molding is still cost-effective. However, its high initial investment for tooling, which can range from $5,000–$50,000 per mold, makes it unsuitable for custom or small-batch production. 3D printing eliminates these mold costs entirely, making it economically viable to produce a single, unique pair of glasses. This makes it the superior choice for personalization and design innovation.

Accessibility and Availability of Custom Frames

The availability of 3D-printed eyewear is rapidly expanding. A growing number of independent eyewear brands and direct-to-consumer companies specialize in this technology. Additionally, more local opticians are beginning to partner with 3D printing labs to offer custom frame services to their clients. The market is experiencing explosive growth, with one forecast predicting the 3D printed eyewear market will reach around USD 14.23 billion by 2033, reflecting its increasing mainstream adoption.

Conclusion: Embrace the Future of Eyewear with 3D Printing

3D printing is more than just a new way to make glasses; it’s a new way to think about eyewear. It shifts the industry from a model of mass production to one of mass personalization, offering tangible benefits at every level. For consumers, it delivers unparalleled comfort, a perfect fit, and the freedom to express their unique style. For manufacturers and designers, it provides a tool for boundless innovation, supply chain efficiency, and sustainable practices.

The convergence of digital design, advanced materials, and additive manufacturing has created a product that is at once highly functional, deeply personal, and environmentally conscious. As the technology becomes even more accessible and material science continues to advance, 3D printing is set to become an indispensable part of the optical world. The future of eyewear is not just in sight; it’s being printed, customized, and perfected, one layer at a time.