TPM3D, a global provider of industrial-grade selective laser sintering (SLS) 3D printing solutions, reinforced its position in the industry through its participation in Rapid+TCT 2025, North America’s largest event for additive manufacturing and industrial 3D printing.

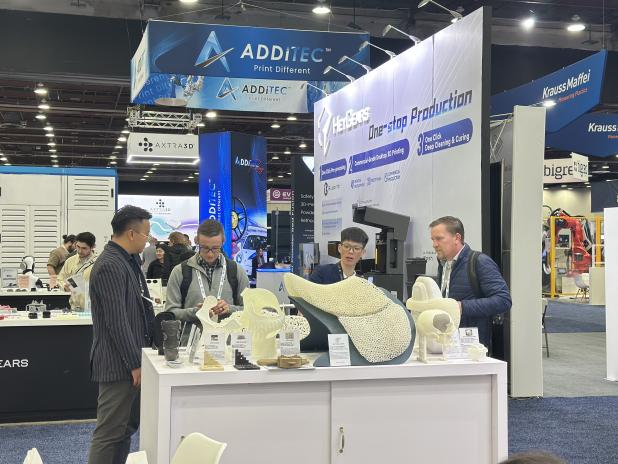

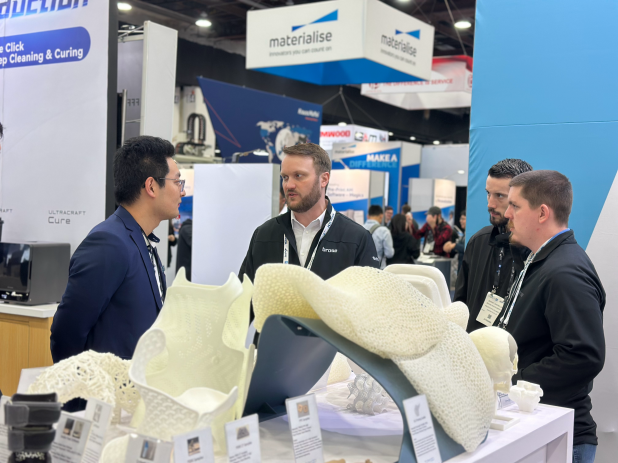

Held from April 8 to 10 in Detroit, the expo brought together professionals from various sectors. As a sponsor of the event, TPM3D had a centrally located booth that showcased material advancements, technical expertise, and collaborative opportunities.

Advancing Materials and Applications

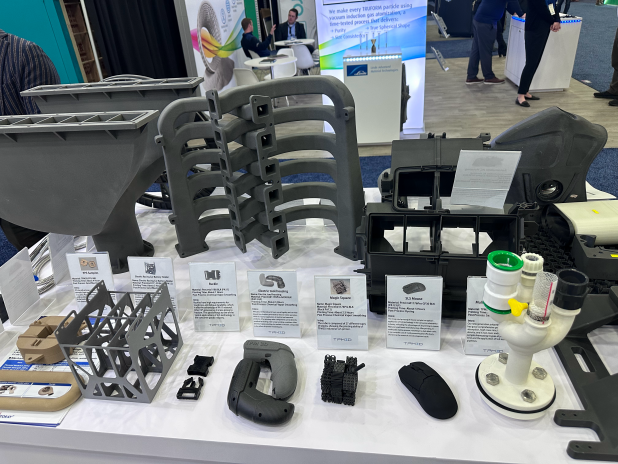

TPM3D presented a range of new materials, including high-toughness co-polyamide materials; the Precimid1174Pro CF15 series, a carbon fiber-reinforced material; polypropylene (PP) with balanced mechanical performance; and high-performance PEEK and PEKK materials designed for applications requiring thermal and chemical resistance.

These materials reflect TPM3D’s continued efforts in advancing material innovations and expanding the capabilities of SLS technology for industrial applications.

Also on display was Touch, a 3D-printed art piece from Tsinghua University Academy of Arts & Design. The artwork illustrated the precision of industrial 3D printing, drawing attention to its intricate details.

Technical Insights and Industry Exchange

As part of the official Tech Hub program, a TPM3D application engineer delivered a speech titled “Empowering Large Size Parts Production with SLS Technology”. The session focused on how TPM3D’s equipment enables efficient production of larger components in the automotive, medical, artistic, and educational contexts. The presentation contributed to the broader exchange of technical insights among exhibitors and attendees.

Throughout the three-day event, TPM3D held in-depth discussions with industry clients and partners on practical applications across various sectors. Many expressed strong interest in the company’s large-format SLS printers and potential for further collaboration.

Looking Ahead

As RAPID + TCT 2025 concludes, TPM3D reaffirms its commitment to advancing 3D printing technologies and fostering industry partnerships. The company remains focused on sharing its latest technological achievements and industry insights with clients, partners, and enthusiasts, in line with its vision to drive progress across manufacturing sectors.

TPM3D invites collaborators to continue the conversation at Formnext 2025, where it will further demonstrate the role of SLS 3D printing in shaping the future of industrial production.