The three-day Formnext Asia Shenzhen concluded at the Shenzhen World Exhibition & Convention Center with TPM3D presenting the potential of selective laser sintering (SLS) technology. As a leader in industrial SLS additive manufacturing, the company highlighted its large-format printing systems, advanced material innovations, and multi-industry application solutions.

Spotlight on Core Equipment: P550DL and PPS

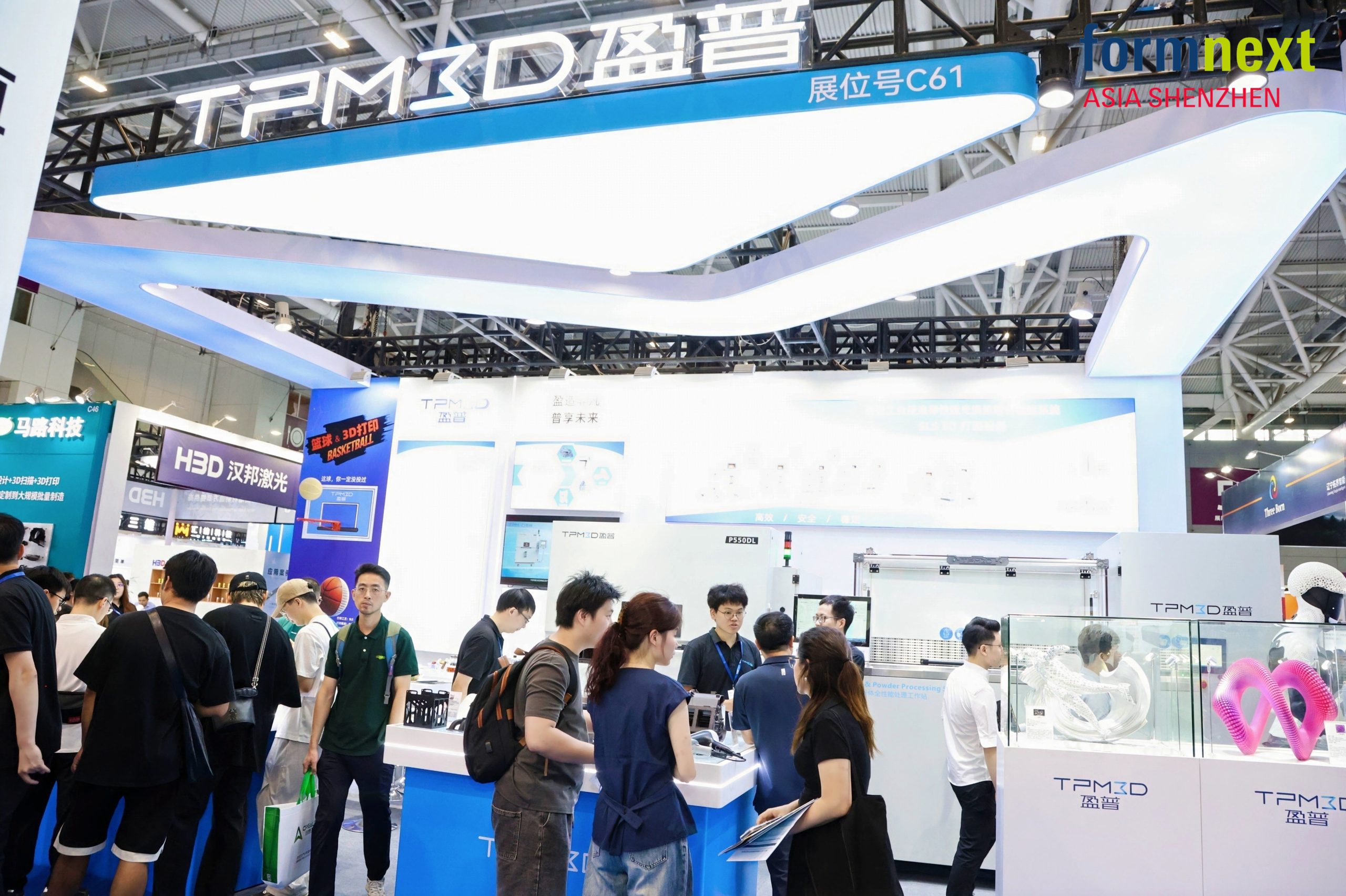

TPM3D’s booth drew strong interest from industry professionals, with the flagship P550DL dual-laser SLS printer and the PPS powder processing station taking center stage.

The P550DL, featuring a build volume of 550 × 550 × 850 mm, delivers efficient large-scale production through its stable dual-laser system. It is designed to support applications ranging from automotive parts and medical rehabilitation devices to rapid prototyping, offering both large-size integrated parts and small-to-medium batch production.

The PPS station complements the P550DL by providing efficient and clean powder recycling and handling. Its intelligent design reduces manual workload and material waste, underscoring TPM3D’s expertise in closed-loop production systems.

Applications Across Industries

TPM3D’s exhibits demonstrated how SLS technology empowers both industrial manufacturing and creative design.

Art & Design: Collaborative sculptures, Companion and Intertwined, developed with Tsinghua Academy of Fine Arts, became popular attractions. Printed entirely with recycled powder, the pieces showcased SLS’s precision, support-free printing, and sustainability benefits.

Consumer Electronics: Lightweight prototypes such as mouse shells, hollow keycaps, and notebook casings offered fast, effective solutions for design validation. The RGB-enabled keycap drew particular attention for its functional and aesthetic appeal.

Industrial Manufacturing: Complex components, including automotive air distribution boxes and internal ducts for metal 3D printers, demonstrated how SLS solves traditional manufacturing challenges while enabling functional integration.

Customization: Ergonomically designed, 10-gram lightweight eyeglass frames provided visitors with a hands-on experience, highlighting opportunities in consumer-grade personalization.

Medical Rehabilitation: Spinal and cervical braces reflected TPM3D’s established expertise in digital medical solutions, delivering precision and comfort for patient care.

Sharing Insights and Innovations

Beyond the exhibition floor, TPM3D actively participated in key forums.

At the 3D Printing Footwear Innovation Forum, the company presented a complete footwear manufacturing solution—covering design, elastic materials like TPU and TPA, certified SLS printers, and post-processing techniques—designed for small-batch, customized, and efficient production.

During its product launch session, TPM3D introduced two new high-performance materials: Precimid1190Pro toughened copolymer nylon and Precimid1174Pro CF carbon fiber-reinforced nylon 12, both aimed at broadening application opportunities in footwear and digital healthcare.

In the Electric Vehicle Additive Manufacturing Forum, TPM3D experts shared insights into how polymer-based SLS can accelerate R&D, reduce costs, and enhance the performance of final parts in electric vehicles.

Strong Engagement and Media Coverage

TPM3D’s booth drew heavy foot traffic throughout the show, with live technical demonstrations enabling both onsite and remote participation. Interactive activities, including a basketball challenge with 3D-printed prizes, added a dynamic atmosphere.

The company also received extensive media attention, with outlets conducting interviews and publishing in-depth reports.

Looking Ahead

While Formnext Asia Shenzhen has concluded, TPM3D’s dialogue with industry peers continues. The event offered not only a platform to showcase the company’s latest achievements in SLS equipment, materials, and applications, but also an opportunity to strengthen connections with partners, customers, and the media.

TPM3D will continue to drive innovation in additive manufacturing, expanding its solutions for diverse industries, and working alongside the sector to shape the future of intelligent manufacturing.