Selective Laser Sintering (SLS) 3D printing is a revolutionary additive manufacturing technology that has transformed prototyping and production across multiple industries. From aerospace to medical implants, SLS enables complex, lightweight, and highly durable parts that traditional manufacturing methods cannot achieve. In this article, we explore the evolution of SLS 3D printing, its industrial applications, advantages, limitations, and the future potential of this cutting-edge technology.

What is SLS 3D Printing?

SLS 3D printing, or Selective Laser Sintering, uses high-powered lasers to fuse powdered materials into solid 3D objects layer by layer. Unlike other 3D printing methods, SLS does not require support structures, allowing designers to create intricate geometries and highly detailed parts. This technology is increasingly being adopted for both prototyping and end-use manufacturing across industries.

The Evolution of SLS 3D Printing

SLS 3D printing was first developed in the 1980s by Dr. Carl Deckard and Dr. Joe Beaman at the University of Texas at Austin. Originally used for rapid prototyping and tool production, SLS has expanded to aerospace, automotive, medical, fashion, and architecture.

Key advancements over the years include:

-

Multi-laser systems: Faster print speeds and higher productivity.

-

Improved software algorithms: Enhanced precision and resolution.

-

Advanced materials: Enabling production of durable, high-performance parts.

Modern SLS printers can produce highly complex parts with exceptional accuracy and repeatability, making them suitable for both prototypes and final production components.

Applications of SLS 3D Printing Across Industries

Aerospace

SLS 3D printing is widely used to create lightweight, durable components with complex geometries, such as air ducts, brackets, and structural elements, which are difficult or impossible to produce with traditional methods.

Automotive

In the automotive industry, SLS is used for rapid prototyping, tooling, and even small-batch production. This reduces lead times, lowers costs, and allows engineers to iterate designs quickly.

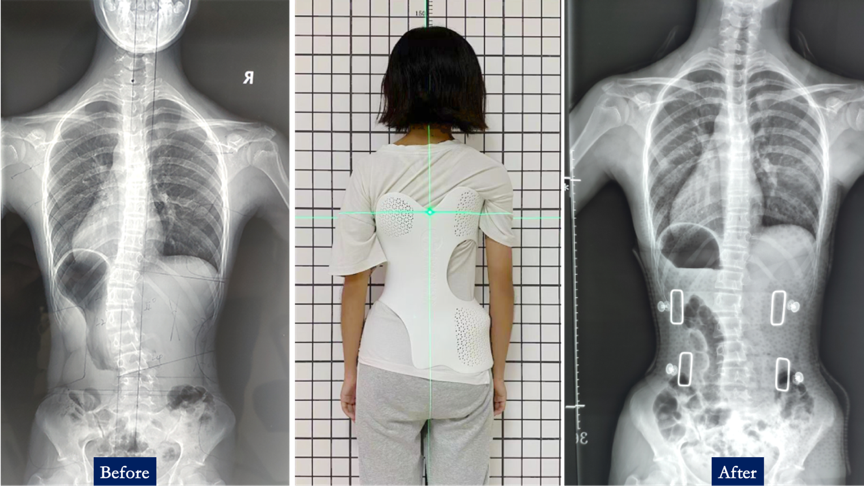

Medical & Healthcare

SLS has revolutionized medical manufacturing by enabling custom prosthetics, implants, and orthotics. Tailor-made designs improve patient comfort, fit, and functionality while accelerating production compared to conventional methods.

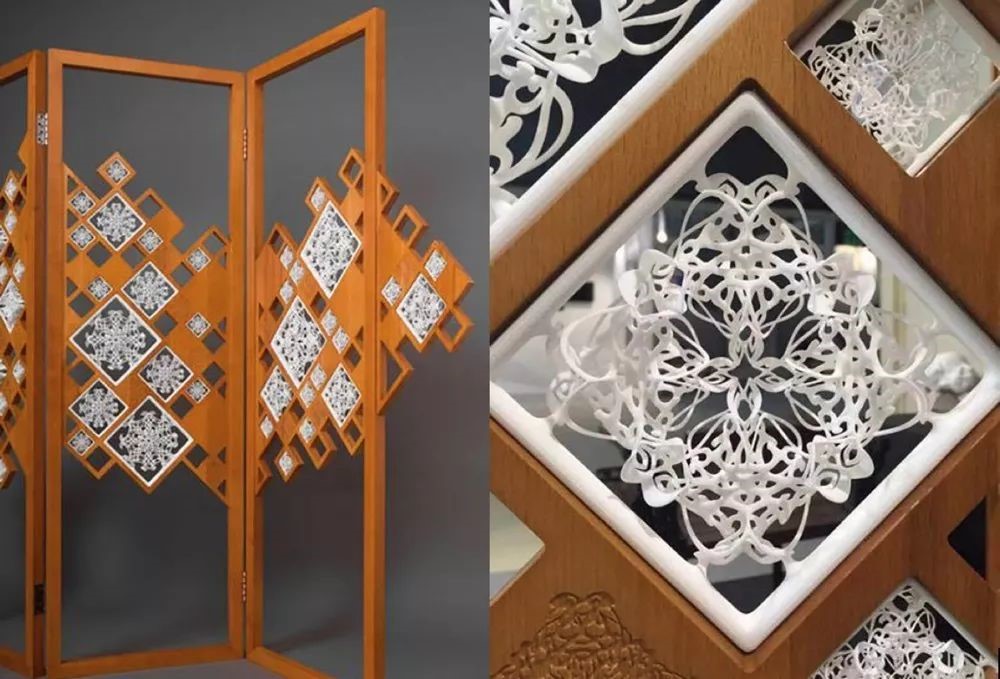

Fashion & Design

Fashion designers leverage SLS to create intricate, unique clothing, accessories, and jewelry pieces. SLS allows experimentation with complex structures that would be impossible to manufacture traditionally.

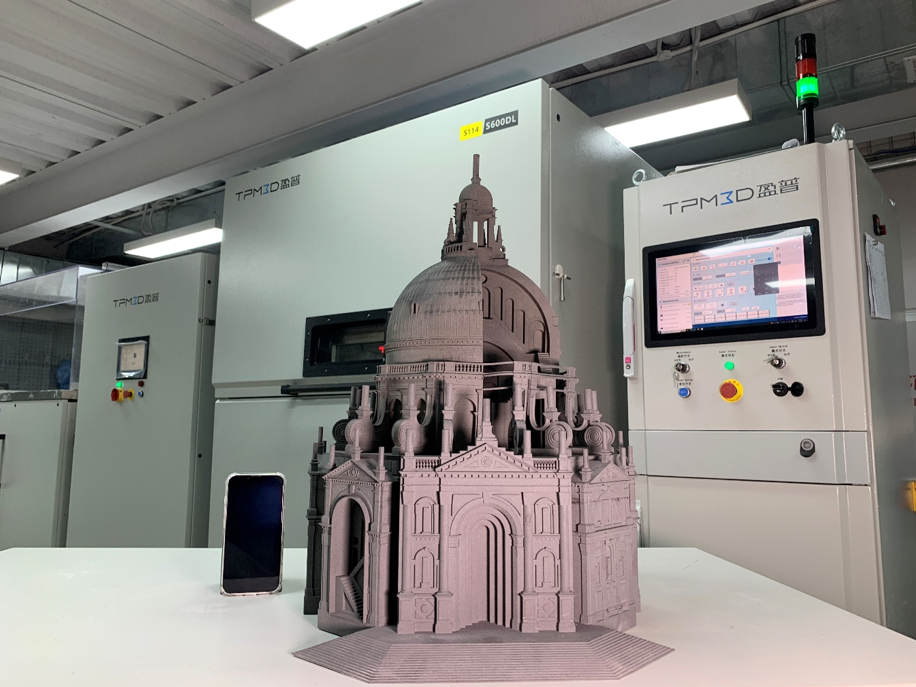

Architecture

Architects use SLS to produce highly detailed scale models and prototypes. The precision and flexibility of SLS printing help architects visualize and refine designs efficiently.

Advantages of SLS 3D Printing

-

Cost-Effective Manufacturing: Eliminates the need for molds and tooling, reducing production costs.

-

On-Demand Production: Parts can be printed as needed, minimizing inventory and storage costs.

-

High Customization: Enables production of complex, personalized designs, especially in medical devices.

-

Time Efficiency: Reduces lead times, supporting industries where speed is critical.

-

Material Efficiency: Minimizes waste by using only the necessary amount of powder.

Challenges and Limitations

While SLS offers numerous benefits, it also faces challenges:

-

Material limitations: Not all polymers and composites are suitable for SLS.

-

Design constraints: Certain geometries may still require post-processing or support structures.

-

Post-Processing Requirements: Parts often need finishing, smoothing, or infiltration to achieve desired properties.

The Future of SLS 3D Printing

SLS 3D printing is set to expand further as technology evolves. Future improvements will focus on:

-

Faster printing speeds

-

Increased accuracy and resolution

-

Expanded material options

-

Wider adoption for industrial-scale production

As SLS continues to advance, it is poised to replace conventional manufacturing methods in many sectors, offering highly customizable, precise, and sustainable production solutions.