The global consumer electronics arena is a battlefield where survival hinges on one rule: speed. Product iterations happen monthly, design innovations emerge endlessly, and user preferences shift in an instant. The player who can transform a brilliant idea into a reliable product the fastest seizes the market advantage.

Consumer Electronics. Image by Freepik

In this race of speed and innovation, traditional manufacturing often shows its limitations. Additive Manufacturing, commonly known as 3D printing, is fundamentally reshaping R&D and production workflows, strengthening the weak links in traditional methods and accelerating the journey from concept to market-ready product.

Among these technologies, Selective Laser Sintering (SLS) 3D printing, with its unique advantages in complex geometries, functional integration, and rapid response, is quietly becoming a powerful engine driving innovative design and agile manufacturing in the consumer electronics sector.

The Trillion-Dollar Consumer Electronics Market: A Crucible of Innovation

The consumer electronics industry is a true global economic titan.

According to Grand View Research, the global consumer electronics market was valued at USD 1,214.11 billion in 2024 and is projected to surge to USD 1,782.60 billion by 2030, growing at a robust compound annual growth rate (CAGR) of 6.6% from 2025 to 2030.

From the smartphones in our pockets and smartwatches on our wrists to gaming consoles at the heart of entertainment and life-enhancing robot vacuums, consumer electronics are deeply integrated into every corner of modern life.

Consumer Electronics Market Size 2020-2030. Source: Grand View Research

This market is not only massive but also distinctly characterized by:

-

Rapid Iteration: Short product lifecycles and fast refresh rates.

-

Design-Driven: Aesthetics, ergonomics, and user interaction experience are core competitive edges.

-

High Functional Integration: The need to pack more components and complex features into increasingly compact spaces.

-

Strong Demand for Personalization: Growing consumer interest in unique designs and customized products.

-

Cost Sensitivity: Fierce market competition makes cost control a paramount priority.

These characteristics place extreme demands on product R&D, design, prototyping, and low-volume pilot production—making “Fast, High-Quality, and Cost-Effective” an industry imperative.

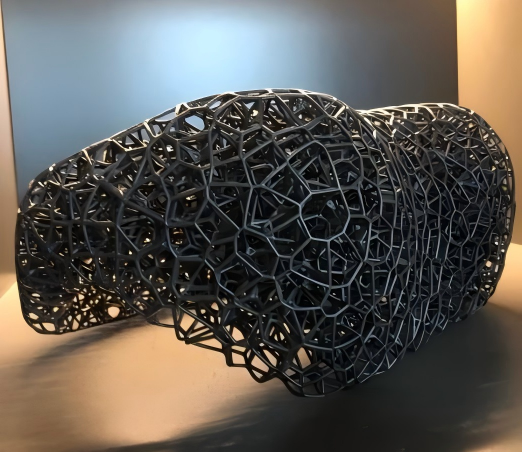

SLS 3D printed keyboard cap and laptop case

3D Printing: The Game-Changer for Consumer Electronics R&D and Manufacturing

Faced with the long cycles, high costs, and lack of flexibility of traditional manufacturing (like mold-injection molding) when dealing with complex designs, rapid iteration, and small-batch production, 3D printing offers an efficient path forward:

-

Accelerates Design Iteration: Obtain physical prototypes within hours or days, drastically compressing design validation cycles.

-

Enables Complex Geometries: Easily create hollow, lattice, internal channel structures, and other forms that are difficult or impossible with traditional methods.

-

Functional Integration & Validation: Directly print assemblies with moving parts or internal structures for functional testing.

-

Flexibility for Low-Volume Production: Economically and efficiently produce customized parts or small batches of spare/final-use parts without mold investment.

-

Reduces Cost & Risk: Thoroughly validate designs before committing to expensive molds, lowering trial-and-error costs.

Among various 3D printing technologies (like FDM, SLA), SLS stands out with its unique process characteristics, offering irreplaceable advantages in consumer electronics.

SLS Selective Laser Sintering: Unique Advantages in Complexity, Strength & Efficiency

SLS technology uses a high-power laser to selectively sinter nylon powder particles, layer by layer, building a solid 3D object. Its core advantages for consumer electronics applications are particularly prominent:

01 True Design Freedom

Unsintered powder naturally supports the part during printing, eliminating the need for dedicated support structures. This allows for the easy creation of complex overhangs, nested parts, and hollow structures (e.g., internal channels, lightweight honeycomb structures, intricate snap-fits), a feat challenging for many other 3D printing technologies that require supports.

3D printed part with complex lattice structure

02 Excellent Mechanical Properties

SLS parts are typically made from Nylon (PA12, PA11), engineering plastics widely used in traditional manufacturing. These materials offer excellent durability, with strength and toughness comparable to or even surpassing those of injection-molded parts in certain aspects.

Good heat and chemical resistance enable them to withstand functional testing loads and environmental challenges, resulting in broad application and recognition across various industries.

03 Superior Surface Quality & Consistency

Finished parts have a uniform, slightly granular surface, high accuracy, and good isotropy. They are suitable for end-use applications and can be vapor smoothed, painted, dyed, or plated to achieve the desired final product finish.

04 High-Efficiency Batch Prototyping/Production

Due to SLS’s unique powder bed fusion principle, parts can be nested densely within the build volume without considering support structures, maximizing Z-axis height utilization.

This makes it ideal for producing large quantities of small parts or multiple different parts simultaneously in a single print run, significantly improving equipment utilization and single-job output efficiency.

05 Mature, Reliable & Diverse Material Options

Nylon powder (primarily PA12) is well-developed, stable, and offers good biocompatibility (suitable for skin contact).

A variety of modified materials are available, including flame-retardant, glass-filled, and carbon-fiber reinforced options. Beyond nylons, materials like TPU and PP can also be printed.

These advantages make SLS the ideal choice for manufacturing consumer electronics components with complex internal structures, those needing to withstand functional loads, or those pursuing unique aesthetic designs, such as housings, brackets, snap-fits, buttons, and internal structural parts.

SLS Applications in Consumer Electronics

SLS technology has been successfully applied across multiple critical stages of consumer electronics development, as evidenced by these application cases from TPM3D:

3D Printed Mouse Housing Prototype

When assisting a peripheral brand with designing an ergonomic mouse, where housing shapes often involve complex, free-form surfaces, TPM3D’s SLS 3D printers rapidly produced high-precision prototypes.

This allowed designers to conduct multiple rounds of ergonomic evaluation, structural assembly verification (testing fit with internal PCB, button mechanisms), and user focus group testing in a very short time, slashing the form factor design iteration cycle and accelerating time-to-market.

3D printed mouse housing prototype using SLS technology

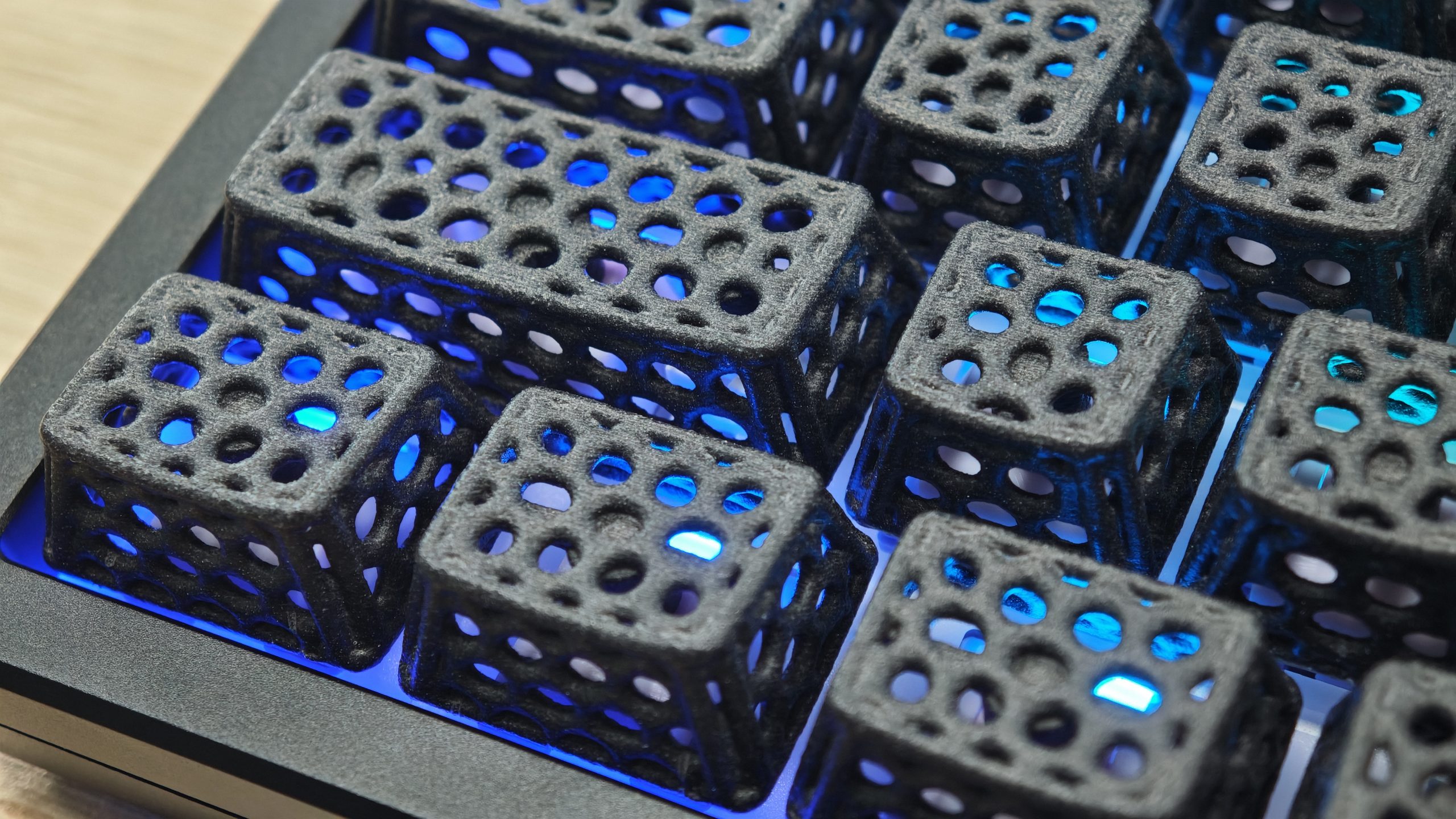

Hollow, Light-Transmissive Mechanical Keyboard Keycaps

Mechanical keyboards, known for superior longevity and tactile feel compared to membrane keyboards, are essential tools for gamers and productivity seekers, fostering a rich ecosystem of products and a vibrant customization market.

To create a unique gaming ambiance, designers conceived keycaps with hollow, light-transmissive structures to enhance the RGB lighting effects of the keyboard kit.

Traditional injection molding couldn’t realize this design.

Hollow, Light-Transmissive Mechanical Keyboard Keycaps 3D printed with SLS technology

TPM3D used SLS technology to print keycaps with intricate lattice structures, replicating the OEM R1-R4 height profile and the ergonomic curve on the keycap top that fits the fingertip, ensuring a comfort level close to that of injection-molded keycaps.

Simultaneously, the nylon material’s inherent strength and durability successfully validated the light effect and ruggedness.

Mechanical keyboard with 3D printed keycaps

Combined with chemical vapor smoothing post-processing, the keycap surface became smooth, hydrophobic, and skin-friendly, making it suitable for use as an end product.

Using 3D printing for design iteration, a complete design-print-validation cycle takes only 2-3 days, increasing iteration speed by nearly 70% compared to traditional methods, even for non-lattice keycap designs, dramatically accelerating R&D progress.

Power Tool Housing R&D Iteration

A power tool manufacturer developing a new handheld device needed a housing integrating complex internal structures (cooling vents, battery compartment snaps, impact ribs) capable of withstanding some impact.

Power Tool Housing Prototype 3D printed with SLS technology

Functional prototypes printed by TPM3D using SLS not only accurately replicated the complex geometry but also, thanks to the strength and toughness of the nylon material, allowed engineers to perform real-world drop tests and grip feel assessments.

This enabled rapid structural optimization, avoiding costly mold modifications later.

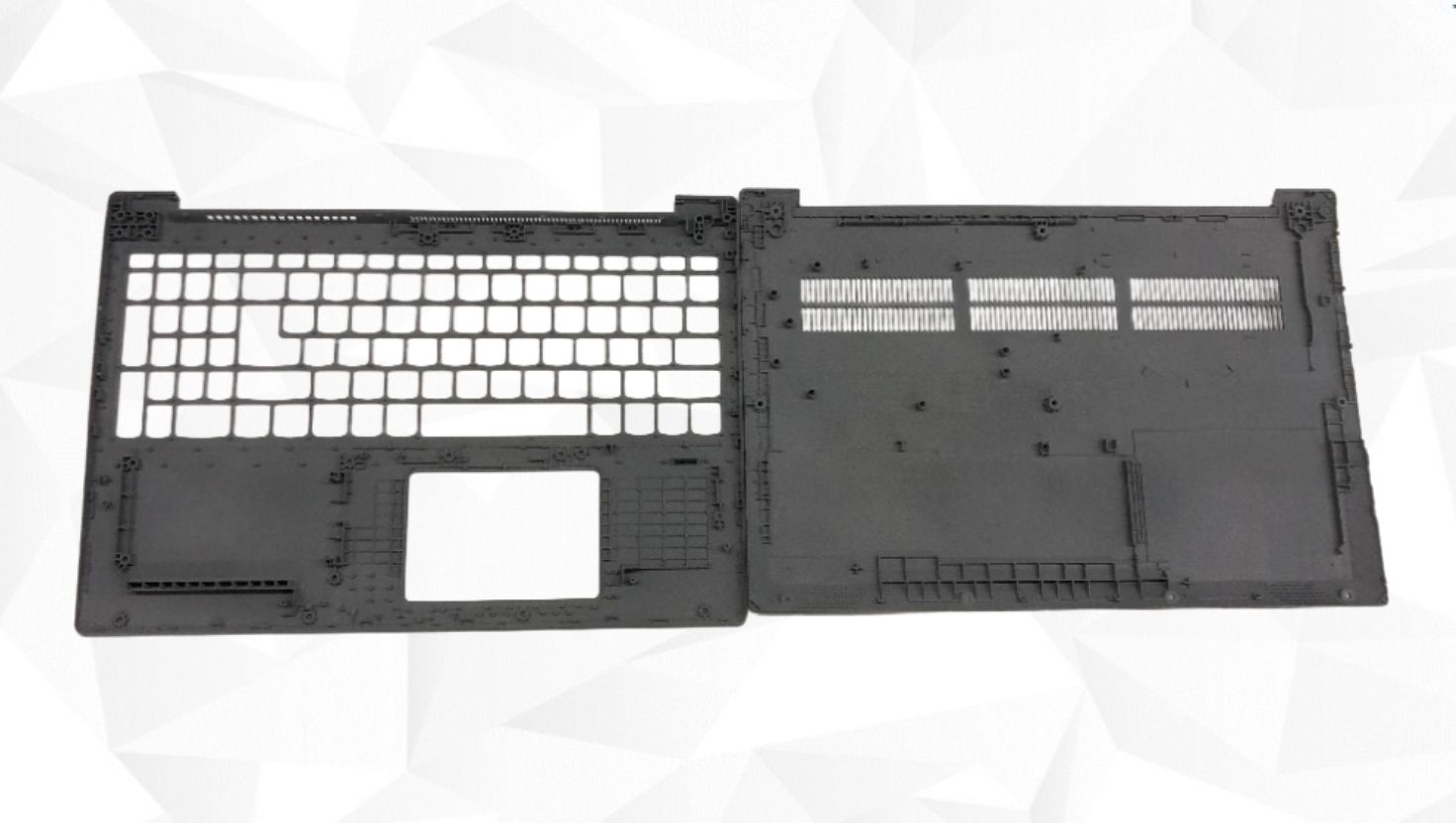

Laptop C/D Cover Structural Assembly Validation

In the compact design of a laptop’s C-cover (keyboard side) and D-cover (base), numerous precise snap-fits, screw posts, port openings, and internal rib layouts are involved.

Using TPM3D SLS to print an entire C/D cover assembly prototype in one go allowed engineers to perform real assembly tests with critical components like the motherboard, battery, and thermal module.

3D printed Laptop C/D Cover with TPM3D SLS technology

This helped identify and resolve potential issues like interference, uneven gaps, or insufficient screw post strength early on, ensuring the reliability of the mass production design and significantly reducing mold commissioning risks.

Future Outlook: SLS Empowers Unlimited Possibilities in Consumer Electronics

As material science, equipment technology, and post-processing continue to advance, SLS’s potential in consumer electronics will be unlocked at a deeper level:

-

Material Innovation: SLS-specific materials with higher strength, better heat resistance, superior flame retardancy (meeting strict safety standards), transparency, flexibility, and even conductivity will continue to emerge, meeting higher demands for safety, performance, and special functions (e.g., flexible wearable components, integrated antennas). High-performance materials like PEEK and PEKK, currently hindered by high costs, hold significant potential for future cost reduction and wider adoption.

-

Low-Volume Production: For customized products (e.g., limited-edition earphone housings, personalized game controllers), on-demand spare parts, or accessories with short lifecycles, the mold-less nature of SLS makes it ideal for small-batch production of end-use parts, especially for complex structural components.

-

Integrated Functional Structures: The design freedom of SLS enables the integration of cooling structures (conformal channels), shock-absorbing/energy-damping structures (lattice infill), and electromagnetic shielding structures within a single component, realizing integrated functional and structural design to enhance product performance and reliability.

-

Automated Post-Processing Boosts Efficiency: Automated powder recovery and surface treatment solutions will further enhance the efficiency and consistency of SLS production, bringing it closer to the standards of mass production.

-

Embracing Sustainability: The high recyclability of unsintered SLS nylon powder (TPM3D’s systems can achieve >80% reuse rates) significantly reduces material waste compared to traditional subtractive manufacturing, aligning with the growing environmental focus within the consumer electronics industry.

In the consumer electronics arena, where innovation and speed are paramount, SLS 3D printing technology is moving from a supporting role to center stage, powered by its unique advantages of “support-free design freedom, excellent mechanical properties, and efficient batch processing.”

It is not just a powerful tool for rapid prototyping but is increasingly becoming an agile manufacturing engine for realizing complex functional structures, accelerating product launches, and supporting small-batch customization.

TPM3D continues to deepen its expertise in equipment, materials, and processes, constantly lowering the application barrier and enhancing the technology’s value.

It is foreseeable that as the technology matures and applications deepen, SLS will become more deeply integrated into the design, R&D, and manufacturing chains of consumer electronics, becoming a key force driving future innovations in the form factor, performance, and personalization of smart devices.

The inherent “speed” gene of the consumer electronics industry is destined to collide with the “freedom, strength, and efficiency” of SLS technology, sparking more innovative flames that will change our lives.