Shenzhen, China – September 11, 2025 – The inaugural China 3D Printing Footwear Innovation Forum officially opened at the Shenzhen Convention and Exhibition Center. TPM3D, a leading manufacturer specializing in Selective Laser Sintering (SLS) 3D printing technology, was invited to attend and delivered a keynote speech titled “Empowering Digital Footwear Manufacturing with TPM3D’s Laser Sintering Additive Technology.”

At the forum, TPM3D joined experts across the industry to explore how 3D printing can break design boundaries and accelerate the footwear industry digital transformation.

With over 20 years of deep expertise in SLS 3D printing, TPM3D is actively advancing its applications in footwear manufacturing. The company has launched a comprehensive end-to-end digital footwear solution, powered by SLS technology. This solution spans the entire process—from design and materials to printing equipment and post-processing—offering the footwear industry an efficient, sustainable, and innovative choice.

Four Core Advantages of TPM3D’s Digital Footwear Solutions

1. Design Freedom: Unlocking Complex Structures Beyond Traditional Molds

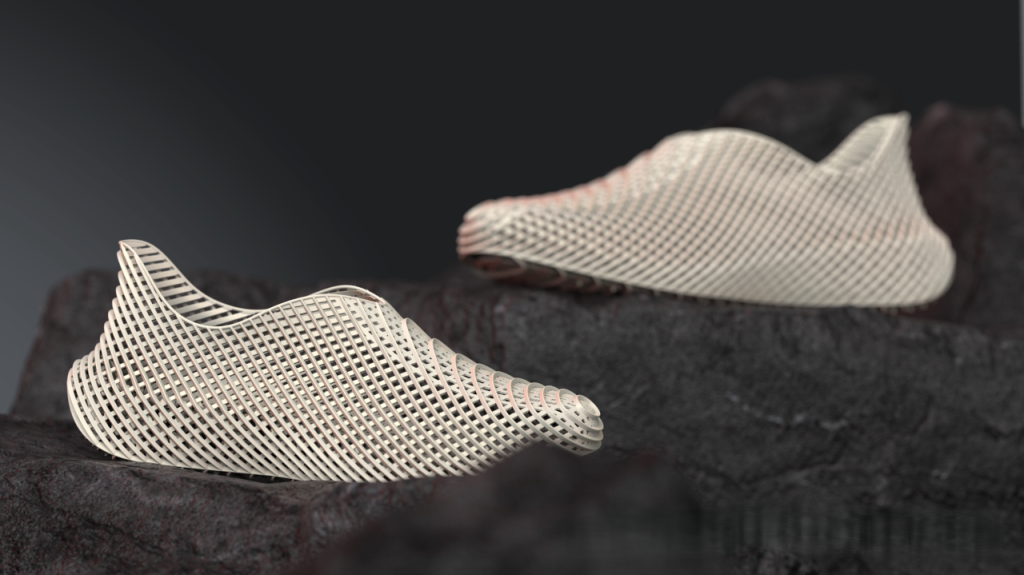

TPM3D’s digital design workflow allows designers to achieve lightweight, breathable, and structurally strong footwear without the limitations of traditional molds. Unlike FDM or stereolithography, SLS printing requires no support structures or directional restrictions, enabling the creation of intricate lattice and hollowed designs while maintaining comfort and wearability.

2. High-Efficiency Production: Large-Format Dual-Laser Printing

The TPM3D P550DL dual-laser SLS printer achieves exceptional productivity, with layer thicknesses of 0.15 mm and scan speeds of up to 22 m/s. In just 38 hours, a single build can produce up to 90 shoes across multiple designs. Intelligent software ensures seamless data-to-print integration with dimensional accuracy within ±0.5 mm—significantly reducing post-processing time and cost.

3. Superior Performance: Balancing Support and Cushioning

Shoes produced with TPM3D’s SLS process are lighter than those made with stereolithography and more durable than FDM prints. The company’s proprietary Precimid material series (including TPU and TPA elastomers) offers outstanding resilience and compression resistance. Combined with unique post-processing techniques, the result is footwear that delivers both structural support and soft cushioning for maximum comfort.

4. Sustainability: Recyclable Materials for a Low-Carbon Future

TPM3D’s SLS technology uses thermoplastic polymer powders with a new material ratio as low as 20% and nearly 100% recyclability of used powder, ensuring high material efficiency. The process requires no organic solvents, and even worn-out shoes can be recycled. This meets China’s GB/T 30102-2024 standards for eco-friendly, recyclable materials, fully aligning with sustainable development goals.

Driving a Smarter, Greener Future for Footwear

TPM3D’s SLS-based digital footwear solutions deliver professional, eco-friendly, and highly efficient alternatives for industry partners. Working alongside other 3D printing technologies such as FDM and stereolithography, TPM3D is committed to expanding consumer choices, infusing the footwear industry with technological vitality, and powering a new era of human-centric, sustainable innovation.