Along with the rapid market growth of polymer powder 3D printing, especially in 2021, when the global market size of this technology surpassed that of photopolymer 3D printing for the first time, it has become the most widely used 3D printing technology for the manufacturing of end products.

Selective laser sintering (SLS) was the earliest polymer powder 3D printing technology and is now the most mature, with a wide range of applications. The market is placing increasingly higher demands on forming volume and printing efficiency, two key indicators of industrial SLS equipment.

Large-Format Industrial SLS Printing Equipment Developed to Meet Market Demand

To accommodate current and future market demand for industrial equipment, TPM3D has launched two large-format dual-laser SLS 3D printers: the P550DL and S600DL. Both models have already been delivered and deployed at customer sites in China and other countries.

TPM3D’s dual-laser series differs from most similar equipment on the market, which is often developed simply by extending the build format.

Instead, TPM3D focuses on improving quality and efficiency in manufacturing. With a wider overlapping area for dual-laser scanning and intelligent scanning collaboration, the two lasers work together to maximize scanning efficiency in a coordinated manner.

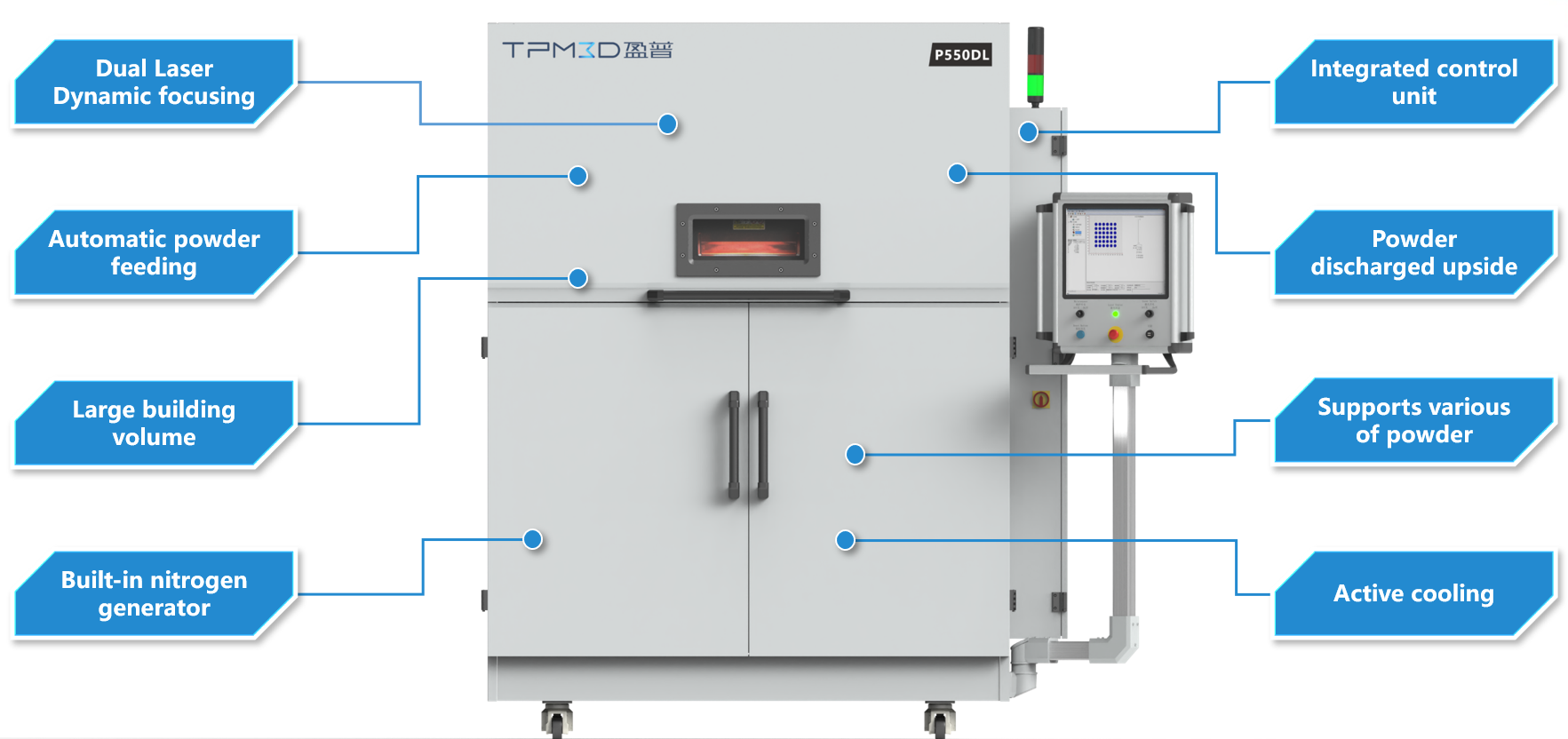

TPM3D P550DL

P550DL, part of TPM3D’s Performance series, can produce various types of large-sized components in a one-off manner or mass-produce small and medium-sized parts. Its build chamber measures 550 × 550 × 850 mm. This model uses two 140W ceramic cavity CO₂ lasers, which provide stable performance and a long service life. The two high-performance dynamic focusing scanning systems operate at a scanning speed of 22 m/s, enabling extremely high production efficiency.

The built-in nitrogen generator eliminates the need for an external unit. P550DL also features TPM3D’s patented active cooling technology, allowing faster cooling after printing and higher cooling efficiency. It extends the service life of powder, with used powder being recyclable indefinitely.

Characterized by a large forming volume, high production efficiency, and cost-effectiveness, P550DL meets the needs of users in automotive, prototyping, healthcare, and other fields. It may be the most cost-effective large-format dual-laser SLS additive manufacturing equipment currently on the market.

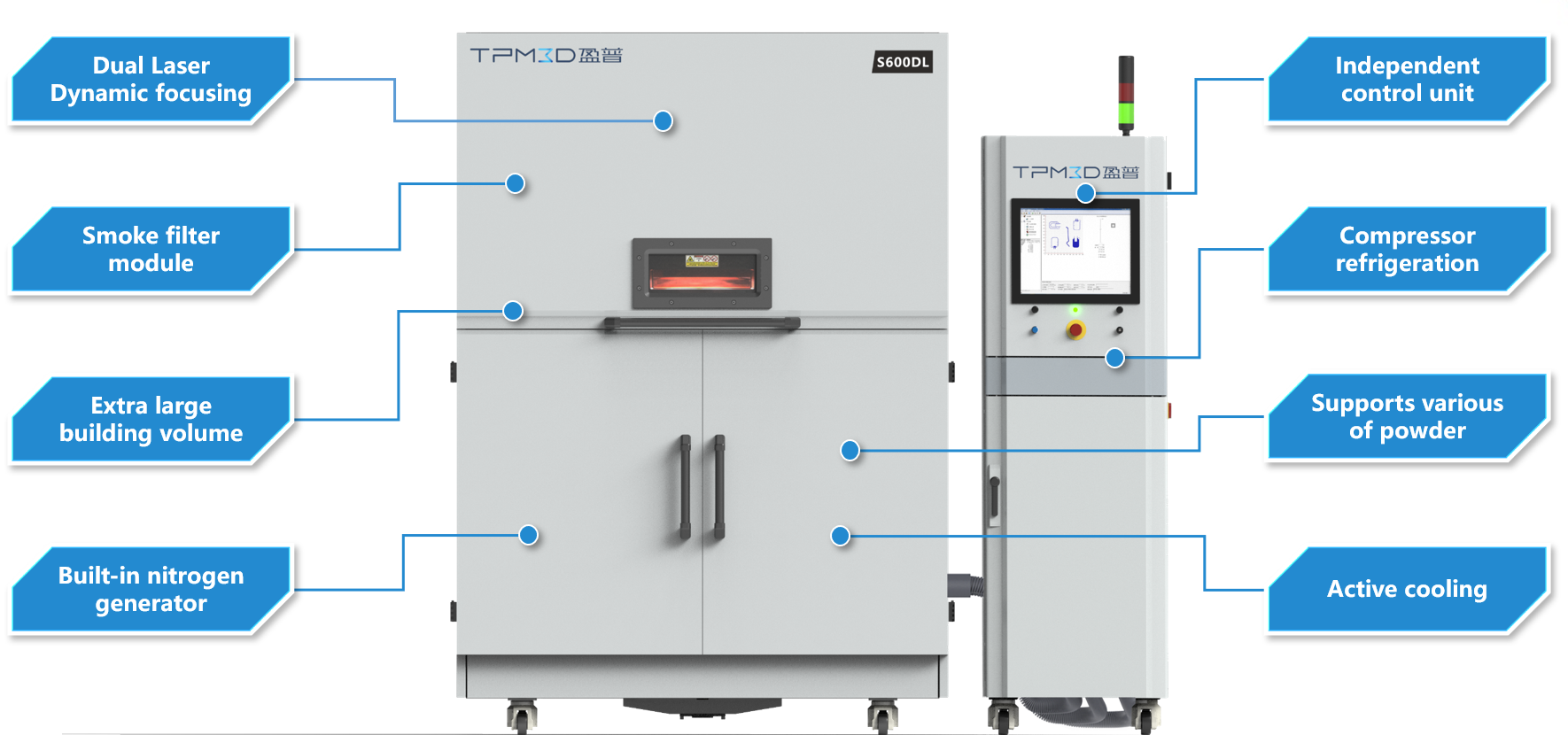

TPM3D S600DL

S600DL, part of TPM3D’s Superior series, is a large-format dual-laser system designed according to the most stringent European Union safety standards. Its build chamber measures 600 × 600 × 800 mm, with a total volume of 288 liters, making it the largest SLS system of its kind currently available. It operates in a balanced manner across all XYZ directions.

Compared to the P550DL, the S600DL offers a larger forming volume and higher efficiency. It features a separate electrical and mechanical design, modular construction, and has obtained TUV CE certification. With a safety level of PL-e, the system includes oxygen concentration detection and smoke filtration modules to ensure stable, safe, and reliable operation.

S600DL enables users in automotive, aerospace, military, healthcare, and other industries to create high-value parts with top-tier performance and efficient production. Since its launch nearly a year ago, S600DL has been highly recognized by overseas industrial users. Its appearance has facilitated the adoption of SLS printing in large-scale manufacturing.

Features of TPM3D Large-Format Dual-Laser Printing Equipment

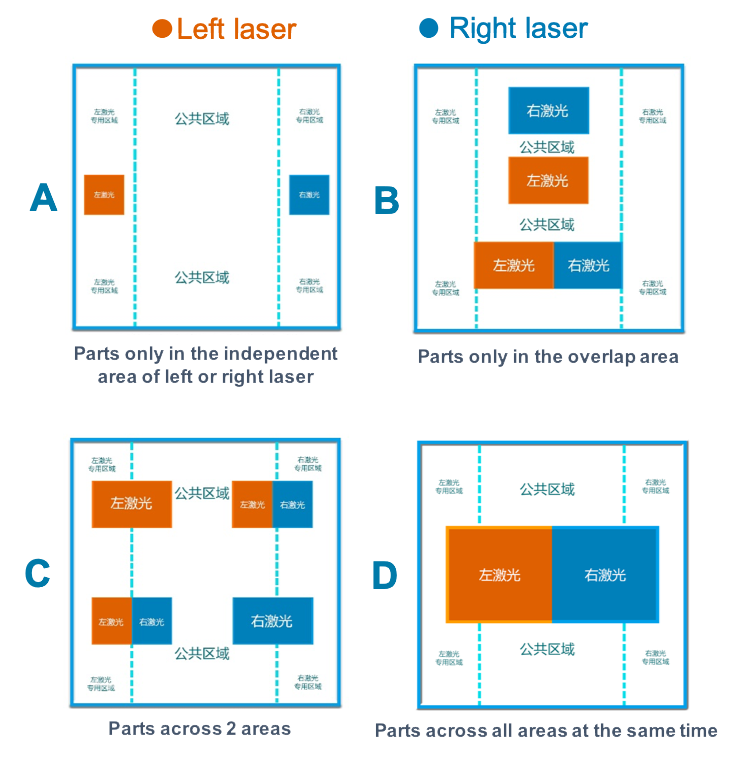

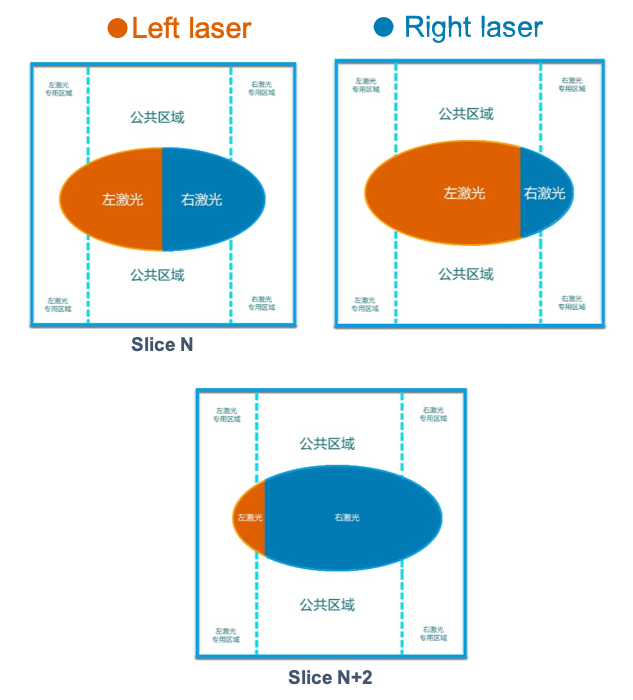

Ensuring the quality and forming efficiency of large-format parts presents several challenges. One major issue for multi-laser equipment is scanning quality control in overlapping areas. If the overlapping area is narrow, the overlap occurs at a fixed position, creating potential fragile points and compromised strength.

TPM3D addresses this with a wider overlapping area and a flexible scanning strategy. The software automatically staggers overlapping positions for each layer, avoiding concentration of fragile points and ensuring strength and quality.

Maximizing scanning efficiency is another focus. TPM3D developed an intelligent, collaborative multi-laser scanning strategy, adaptive to different part shapes, scanning areas, and parameters. This allocates scanning tasks between lasers, improving overall printing efficiency by more than 45% compared to single-laser equipment.

Finally, the Parts & Powder Processing Station (PPS) is an efficient, clean production solution independently developed by TPM3D. With larger build volumes, cleaning and powder recycling workloads increase significantly. Manual processes would be inefficient and costly without intelligent, automated powder management.

TPM3D PPS integrates parts cleaning, powder collection, filtration, virgin powder addition, proportioning, mixing, and automatic powder supply, minimizing environmental impact and reducing time and labor costs for users.