Electrification and automation have developed at an unprecedented pace. Among the most widely used protective devices are molded-case circuit breakers (MCCBs), known for their reliable overload and short-circuit protection. MCCBs are compact, structurally complex, and essential across industries, which makes prototyping and testing critical for product development.

Traditionally, appliance manufacturers relied on silicone coating processes or CNC machining to produce prototypes for verification. However, these methods came with long processing cycles and high costs. For companies producing dozens or even hundreds of new products annually, this approach became a significant bottleneck.

One world-renowned customer of TPM3D, a leader in smart energy solutions, faced exactly this challenge.

Customer Profile

The customer is a global smart energy solution provider with annual sales exceeding RMB 80 billion and operations in more than 140 countries and regions. Its portfolio includes power distribution, terminal appliances, motor control and protective devices, and industrial automation systems.

To accelerate innovation, the company adopted the TPM3D P360 laser sintering system combined with a Parts & Powder Processing Station (PPS) for R&D and trial production of its low-voltage electrical appliances.

Product Development with SLS 3D Printing

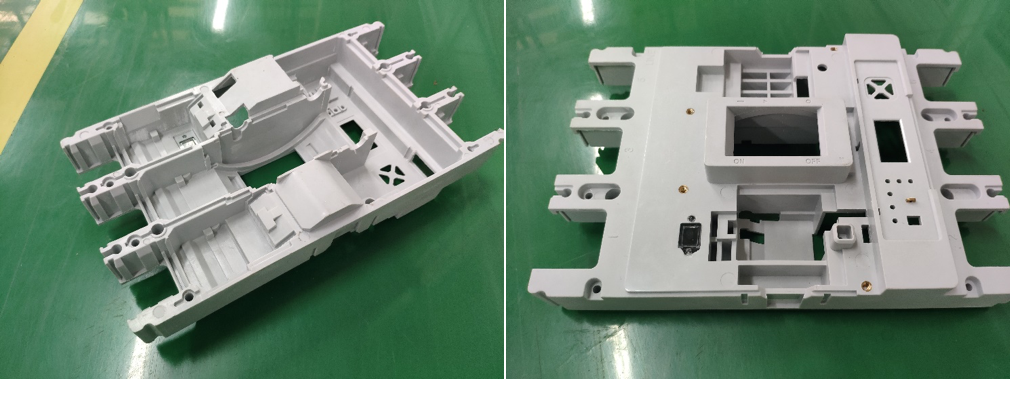

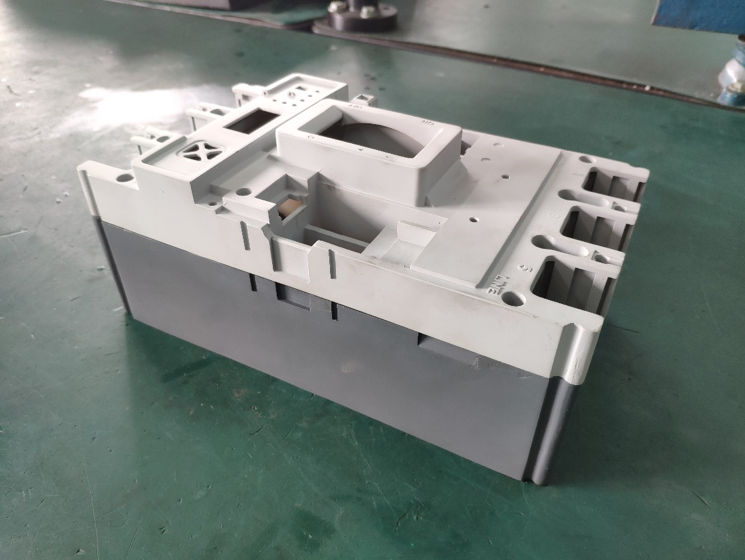

The company develops and manufactures more than 10,000 new electrical products annually, requiring rapid prototyping and frequent verification. With TPM3D’s P360 system, they now produce functional prototypes such as MCCB cases and other structural components directly with selective laser sintering (SLS).

After printing, each sample undergoes assembly verification and a series of functional tests, including:

-

Strength test

-

Long delay test

-

Insulation test

The accuracy requirement for assembly verification is as tight as ±0.2 mm, and SLS parts consistently meet this benchmark.

For materials, the customer uses Precimid1172Pro GF30 — a 30% glass bead reinforced nylon 12 developed by TPM3D. It provides excellent strength, impact resistance, and insulation properties. Test results confirmed that:

-

Thermal deformation temperature: up to 184.4℃

-

Printed MCCB cases could withstand 80℃ for 4 hours in a thermostat without deformation, fully meeting long-delay test requirements.

In practice, MCCB cases produced via SLS perform on par with injection-molded parts, validating their suitability for both prototyping and functional testing.

Environmentally Friendly Production

Alongside the P360 system, the customer implemented TPM3D’s Parts & Powder Processing Station (PPS), launched in 2018 as the first of its kind in Asia. PPS integrates:

-

Parts cleaning

-

Powder recycling and mixing

-

Powder feeding and collection

This automation eliminates many manual operations that are otherwise time-consuming, unsafe, and prone to dust pollution. PPS is also certified under National Dust Explosion-Proof Zone 22 standards and holds international CE certification, ensuring both safety and environmental protection.

The result is a clean, tidy, and efficient workshop environment that significantly improves operator safety.

Cost Reduction and Efficiency Improvement

The shift to SLS 3D printing has had a dramatic impact:

-

Before SLS:

-

Prototyping via CNC or outsourced silicone coating required 5–6 days.

-

Each MCCB case cost around RMB 4,000/set.

-

-

With TPM3D P360:

-

Parts are ready for testing in just 48 hours — a time saving of over 60%.

-

Cost reduced to under RMB 700/set — an 80%+ reduction.

-

On average, the customer now achieves 2–3 full chamber prints per week, resulting in significant savings — approximately RMB 700,000 annually, while boosting R&D throughput.

Customer Feedback

“TPM3D’s P360 system is convenient and fast; PPS reduces manual intervention while achieving high processing efficiency of parts and powder. The solution saves time and cost and ensures the tidiness and safety of the environment.”

Conclusion

By adopting TPM3D’s P360 laser sintering system and PPS, this global energy leader has transformed its R&D process for low-voltage electrical appliances. The integrated solution has not only accelerated product development and reduced costs but also ensured a cleaner, safer, and more sustainable production environment.

For an industry where speed, precision, and safety are paramount, SLS 3D printing is proving to be a game-changer.