Selective Laser Sintering (SLS) 3D printing technology has long been recognized for its ability to produce functional parts for industries including automotive, aerospace, medical devices, consumer electronics, and education. Traditionally, SLS has been used for rapid prototyping and small- to medium-scale customized product manufacturing. Its advantages include high precision, mechanical strength, and compatibility with a wide range of polymer materials.

Recently, however, SLS technology has found a novel application in the world of high-end BB air guns and modification kits, opening up new possibilities for DIY enthusiasts and small-batch manufacturers.

BB Air Guns and the Demand for Quality Customization

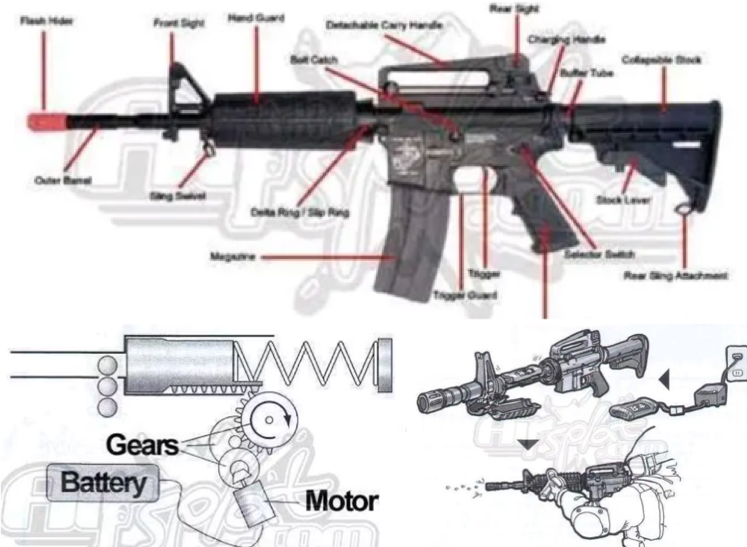

BB air guns, which fire non-lethal plastic pellets (BB bullets) using compressed air or gas, come in electric and inflatable variants. While the BB gun player community is relatively niche, users often demand high-quality, technically robust products and are willing to invest in premium components and modifications.

Until now, many enthusiasts have relied on desktop 3D printing technologies such as FDM or DLP to produce customized parts. While flexible for personal use, these methods have limitations:

-

Slow printing speed

-

Weak mechanical strength, especially along the Z-axis

-

Pronounced layer lines require sanding and finishing

-

Limited suitability for high-end, small-batch production

TPM3D Brings SLS to BB Air Gun Customization

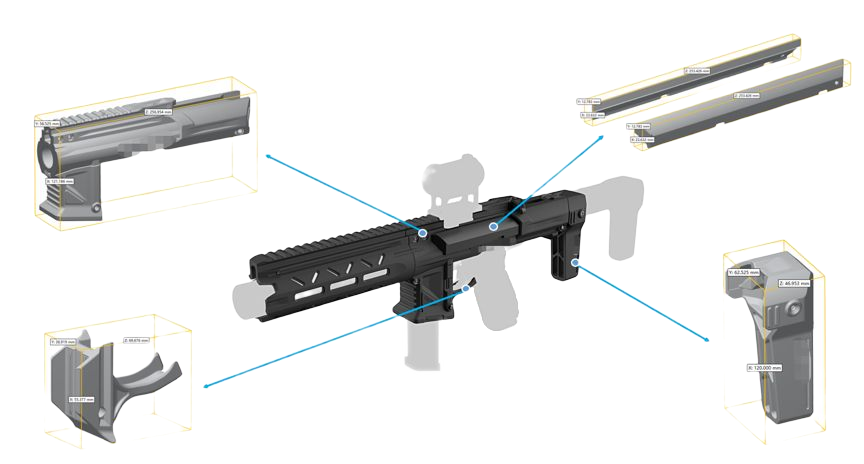

An overseas brand specializing in high-end customized BB guns sought to overcome these limitations using SLS 3D printing. TPM3D was tasked with producing a carbine expansion kit for the AAP01 pneumatic BB pistol. This modular kit allows the pistol to be converted into a carbine and adapted for additional attachments such as sights.

Key components printed included the trigger guard, gun stock, and gun stock slide, using Precidim1172Pro BLK, a grey-black nylon 12 material known for its mechanical strength, temperature resistance, and up to 80% powder reuse rate. This allowed for accurate, cost-effective production of high-quality customized parts.

Industrial-Grade SLS for Small-Batch Efficiency

The printing was completed on the TPM3D P360 industrial SLS printer, featuring a build chamber of 360 × 360 × 600 mm and compatibility with nylon and composite materials, including PA11, PA12, PA6X, as well as PP and TPU.

The P360 delivered:

-

High-quality prints with minimal layer lines

-

Dimensional accuracy within ±0.2 mm (installation holes within ±0.1 mm)

-

Production of over 100 parts (20 complete kits) in a single batch

The result was a set of modular BB gun components that not only met precise mechanical specifications but also offered superior surface quality and consistent performance, demonstrating the value of SLS for small-batch, high-end product manufacturing.

Expanding the Boundaries of SLS

This application illustrates how SLS 3D printing can extend beyond traditional industrial uses into niche consumer markets requiring durability, precision, and efficiency. For BB air gun enthusiasts and small-scale manufacturers, SLS provides a reliable solution for customization, cost-efficiency, and rapid production, unlocking new creative possibilities in product design and performance.