On December 24, at the 2025 Additive Manufacturing Industry Development Forum and Annual Conference, the China Additive Manufacturing Industry Alliance and the National Additive Manufacturing Product Quality Inspection and Testing Center (Jiangsu) officially released the 2025 High-Quality Additive Manufacturing Products List. Leveraging its deep technical expertise and sustained system-level innovation in industrial-grade additive manufacturing, TPM3D achieved simultaneous recognition across three core categories—materials, components, and equipment. This distinction places the company among a select group of enterprises honored across multiple domains, underscoring its leading capability to deliver comprehensive, end-to-end solutions.

From Materials to Equipment: Demonstrating Full-Stack Technological Capabilities

In this selection, TPM3D’s ability to stand out across three major categories is underpinned by a complete technology loop it has built—spanning proprietary materials, core equipment, and intelligent production systems.

-

Additive Manufacturing–Specific Materials

-

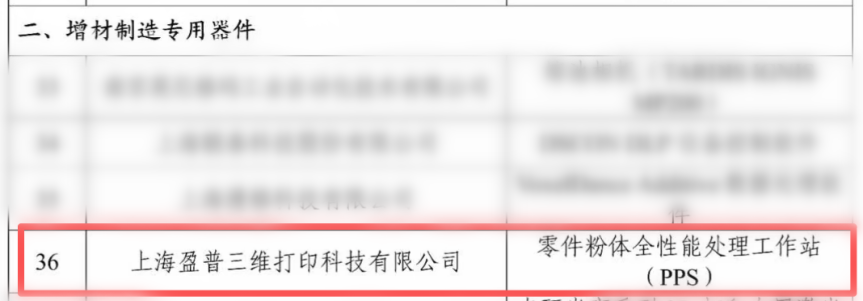

Additive Manufacturing–Specific Components

-

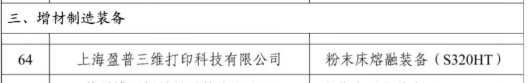

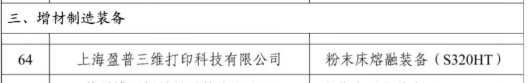

Additive Manufacturing Equipment

Looking ahead, TPM3D will continue to focus on core technological innovation, deepen the coordinated development of materials, components, and equipment, and further enhance its overall additive manufacturing solutions, working alongside industry partners to drive high-quality growth in the additive manufacturing sector.