Polyether ether ketone (PEEK) and polyether ketone ketone (PEKK) are among the types of non-metal 3D printing materials that closely resemble the mechanical properties of metals. They possess numerous outstanding characteristics, including high temperature resistance, chemical resistance, insulation, flame retardancy, low friction self-lubrication, biocompatibility, and high temperature sterilization.

These advantages make them popular materials in high-end applications such as automotive, defense, aerospace, and medical industries. However, the printing of high-performance polymers is particularly challenging due to their strict requirements for molding temperature. This necessitates the use of printing equipment with advanced temperature control and relevant printing parameter control capabilities, while also ensuring good stability.

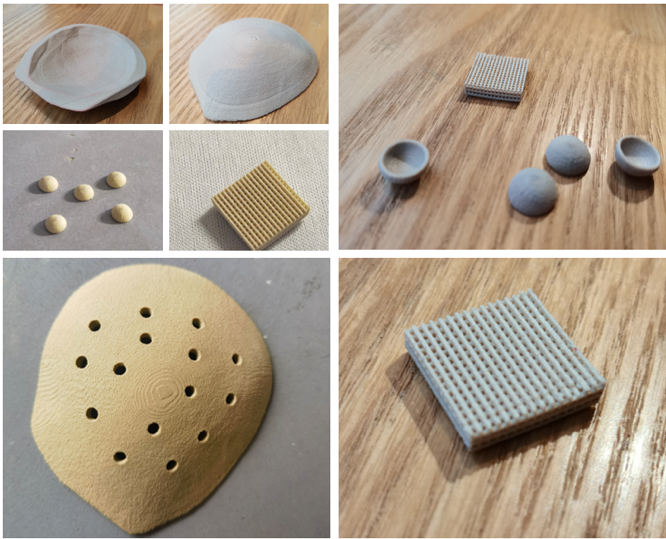

PEEK model printed by SLS(left) and printed by FDM(right)

About Southern University of Science and Technology

Southern University of Science and Technology is a national “Double First Class” university, a national pilot university for comprehensive reform of higher education, and a high-level university of science and engineering in Guangdong Province.

The Department of Mechanical and Energy Engineering, where this research is based, focuses on:

-

Intelligent manufacturing

-

Forming manufacturing and 3D printing

-

Precision machining technology

-

Soft matter design and manufacturing

-

Energy engineering

-

Robotics and automation

The department is equipped with a complete set of 3D printers and 3D scanning teaching and research equipment, including electron beam, laser, light curing, thermal fusion, and adhesive bonding technologies, along with relevant design and simulation software.

Samples printed using TPM3D’s high-temperature printer S320HT

Collaboration and Research Focus

The Department of Mechanical and Energy Engineering, in collaboration with the Shenzhen Key Laboratory for High-performance Additive Manufacturing of Advanced Materials, has successfully procured and utilized the TPM3D S320HT high-temperature laser sintering additive manufacturing system.

Additionally, the university developed its own PEEK polymer material and molding techniques. Main application areas include:

-

Medical implants

-

Biocultivation

-

High-end manufacturing

The research team has achieved stable and controllable printing processes, producing high-performance components with strong industrial potential.

Features of TPM3D S320HT System

The TPM3D S320HT laser sintering additive manufacturing system has obtained TÜV CE certification from Germany’s TÜV Rheinland and is in use by multiple customers. It is capable of maturely printing PEEK and PEKK materials, offering several advanced features:

-

Ultra-high temperature laser sintering printing – Powder bed up to 350℃, forming cylinder up to 300℃.

-

Flexible printing size – 320×320×380mm, suitable for both R&D and small-scale production.

-

Flexible powder replacement – Open breakout station (OBS) for fast cleaning, filtering, and material switching.

-

Oxygen concentration monitoring – Real-time oxygen monitoring inside the system.

-

Built-in nitrogen generator – Eliminates the need for external tanks, reducing costs.

-

Adjustable temperature by height – Increases freedom in placement and space utilization.

-

Flexible part addition/removal – Powder cylinder and chamber can be separated for urgent print jobs.

-

Optimized powder spreading device – Intelligent dual scraper system with wide material compatibility.

-

High material reusability – Adding 20% new powder to recycled PA12 achieves excellent results.