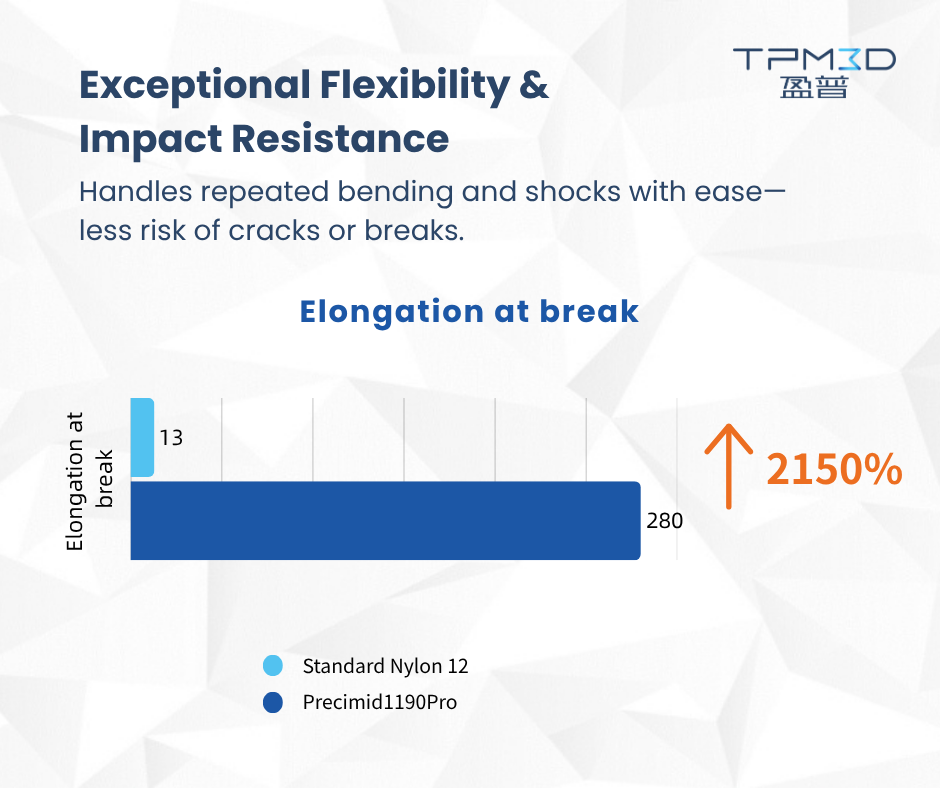

TPM3D, a specialist in Selective Laser Sintering (SLS) 3D printing solutions, has introduced Precimid1190Pro, a new high-toughness copolymer nylon powder featuring 280% elongation at break. Designed for demanding applications requiring enhanced flexibility and durability, the material is well-suited for use in medical rehabilitation devices, personalized consumer goods, and functional components.

Significantly Enhanced Toughness

Available in black and white, Precimid1190Pro offers a substantial improvement in ductility compared to standard PA12 materials such as TPM3D’s Precimid1172Pro, which typically delivers 8% to 17% elongation at break. The 280% stretchability represents an increase of over 2150%, allowing the material to endure considerable deformation before breaking. This performance makes it particularly resistant to impacts and repeated bending, reducing the risk of brittle failure in end-use parts.

High Precision and Reusability

In addition to its mechanical properties, Precimid1190Pro meets the precision demands of the SLS process. It accurately renders complex geometries while maintaining excellent surface quality. The material also supports a low refresh rate of 15%, offering advantages in powder reusability. This translates to reduced production costs, improved efficiency, and lower material waste.

Key Applications: Rehabilitation and Wearable Comfort

Thanks to its balance of flexibility and durability, Precimid1190Pro offers strong potential for applications in custom medical rehabilitation and wearable designs.

1. Customized Rehab Braces

Ideal for wrist, palm, and ankle orthoses, the material ensures consistent support while resisting deformation during long-term use. When post-processed using chemical vapor smoothing, the printed braces gain a smooth, breathable surface that improves comfort and hygiene. The material can also be dyed to match personalized design preferences, while brace shapes can be tailored to fit individual anatomy

2. Eyewear Frames

Precimid1190Pro also provides practical advantages for 3D-printed eyewear frames, offering greater resistance to accidental bending or drops. The material’s flexibility supports thinner, lighter, and more ergonomic frame designs without compromising durability.

Supporting the Next Generation of Flexible Applications

With its high elongation at break and stable print performance, Precimid1190Pro addresses the growing demand for versatile, user-friendly materials in the SLS 3D printing space. Its introduction offers manufacturers new possibilities for creating durable, customized products across a range of industries—particularly where flexibility, comfort, and reliability are key.