Formula Student China is a key platform for developing future automotive engineering talent. The competition features three categories: Formula Student Combustion China (FSC), Formula Student Electric China (FSEC), and Formula Student Autonomous China (FSAC).

As a leading manufacturer of SLS 3D printing equipment in China, TPM3D has supported the event for three consecutive years, aiming to give young engineers more opportunities to explore and apply additive manufacturing. In 2021, TPM3D sponsored the driverless racing teams from Beijing Institute of Technology and Tongji University.

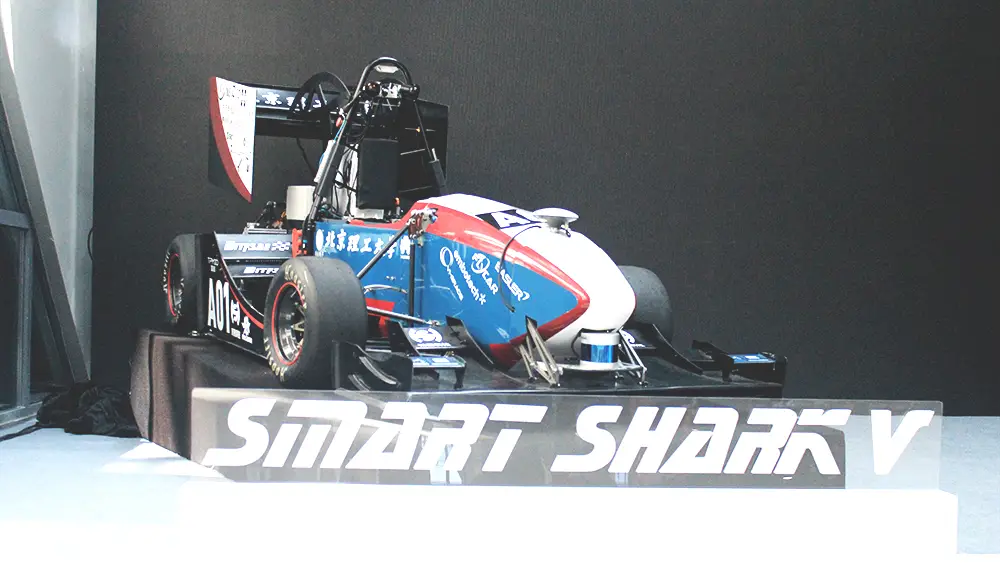

Beijing Institute of Technology Driverless Racing Team

Founded in 2007, the Beijing Institute of Technology Driverless Racing Team (BITFSD) developed the world’s first driverless formula car built by university students in 2016. The team went on to win championships in 2017, 2018, and 2020, becoming the only “triple champion” in the history of China’s university-level Formula Student competitions.

In 2021, TPM3D supported BITFSD with SLS 3D printed parts in five areas:

-

Low-voltage box shell

-

High-voltage box shell

-

Energy meter shell

-

Flame-retardant battery module frame

-

Industrial computer shell

These components were integrated into the electronic control, energy, braking, and body systems of the car, helping reduce weight, improve safety, and enhance overall performance.

Applications of TPM3D Materials

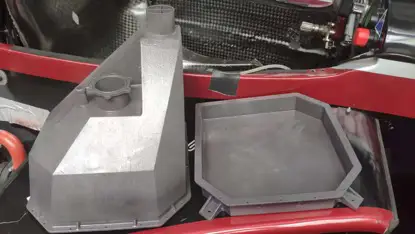

Battery Module Frame

The battery module is the heart of the energy system. Previously, BITFSD used bonded glass fiber boards to make the frame. In 2021, the team switched to TPM3D’s Precimid1171 FR (PA12), a flame-retardant material certified to UL94 V-0. The new design reduced weight by nearly 37% while improving protection, durability, and surface quality.

Energy Meter Shell

Each car includes an energy meter to ensure the power output remains below 80 kW for safety. For this part, BITFSD chose Precimid1172Pro GF30 (PA12). Reinforced with 30% glass fiber, the material offers strong mechanical properties, excellent wear and impact resistance, and a heat deflection temperature of 184 °C (@0.45 MPa), making it well-suited for demanding conditions.

Industrial Computer and Camera Shells

TPM3D’s Precimid1172Pro (PA12) was also used for the industrial computer and camera housings. Lightweight yet tough, the material provides reliable protection while reducing overall weight, contributing to both safety and performance on the track.

Looking Ahead

By integrating advanced SLS 3D printed components, BITFSD has improved both the safety and efficiency of its driverless racing car. TPM3D is proud to support the team’s innovation and looks forward to seeing their continued achievements in the seasons ahead.