As digital tools transform the creative process, the intersection of cultural design and advanced manufacturing is opening new possibilities for artists and innovators. One recent example is “Shattered · Symbiosis”, a sculpture created by a doctoral student from Tsinghua University’s Academy of Arts & Design, brought to life through TPM3D’s large-format SLS 3D printing technology.

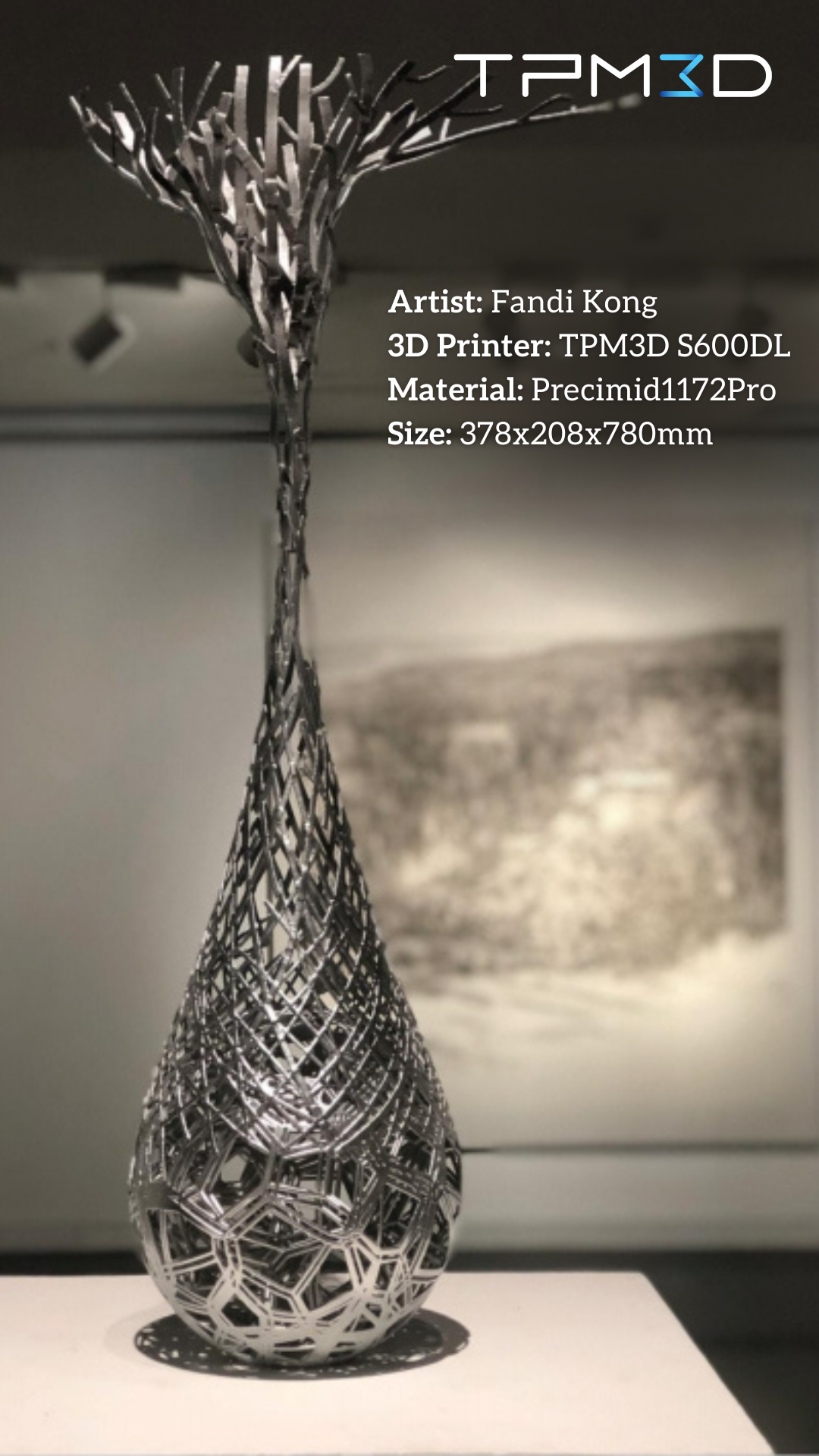

The artwork, inspired by the symbiotic relationship between water and wood, features intricate, organic branches converging into the form of a single falling droplet. Its delicate geometry and large scale posed great challenges for traditional fabrication methods—making additive manufacturing the only viable path from concept to reality.

To realize the sculpture, the artist used TPM3D’s S600DL system, which offers a generous build volume of 600 × 600 × 800 mm. This allowed the full 780 mm-tall piece to be printed in one run—preserving its structural integrity and eliminating the need for assembly.

Using TPM3D’s proprietary Precimid1172Pro white PA12, the print captured subtle surface textures while delivering the mechanical strength needed to support the sculpture’s finest elements. Some parts measured just 16 mm in diameter, with the thinnest features under 1 mm—dimensions that would typically compromise structural performance in other 3D printing processes.

Unlike FDM and SLA, which often require extensive support structures and careful post-processing, TPM3D’s SLS technology enables support-free printing. The sculpture’s complex mesh base and internal geometry were printed cleanly without added supports, reducing the risk of damage and minimizing post-production labor.

SLS’s isotropic strength and durability also ensure that pieces like this are better suited for long-term public display—making it a strong choice for artists, museums, and cultural institutions.

With over two decades of experience in selective laser sintering, TPM3D continues to support the cultural and creative industries with high-performance equipment and materials. As demand grows for customized, large-format, and highly detailed works, TPM3D remains committed to helping creators push the boundaries of digital fabrication.