A drone frame weighing just 6 grams has been successfully produced using TPM3D’s Selective Laser Sintering (SLS) 3D printing technology and advanced materials. The result highlights how additive manufacturing is helping drone makers achieve lighter, stronger designs—quickly and efficiently.

As drones are increasingly used across sectors–from mapping and agriculture to rescue, racing, and inspection–manufacturers face mounting pressure to reduce weight while maintaining performance. 3D printing, and particularly SLS, is proving to be a valuable tool in meeting these demands.

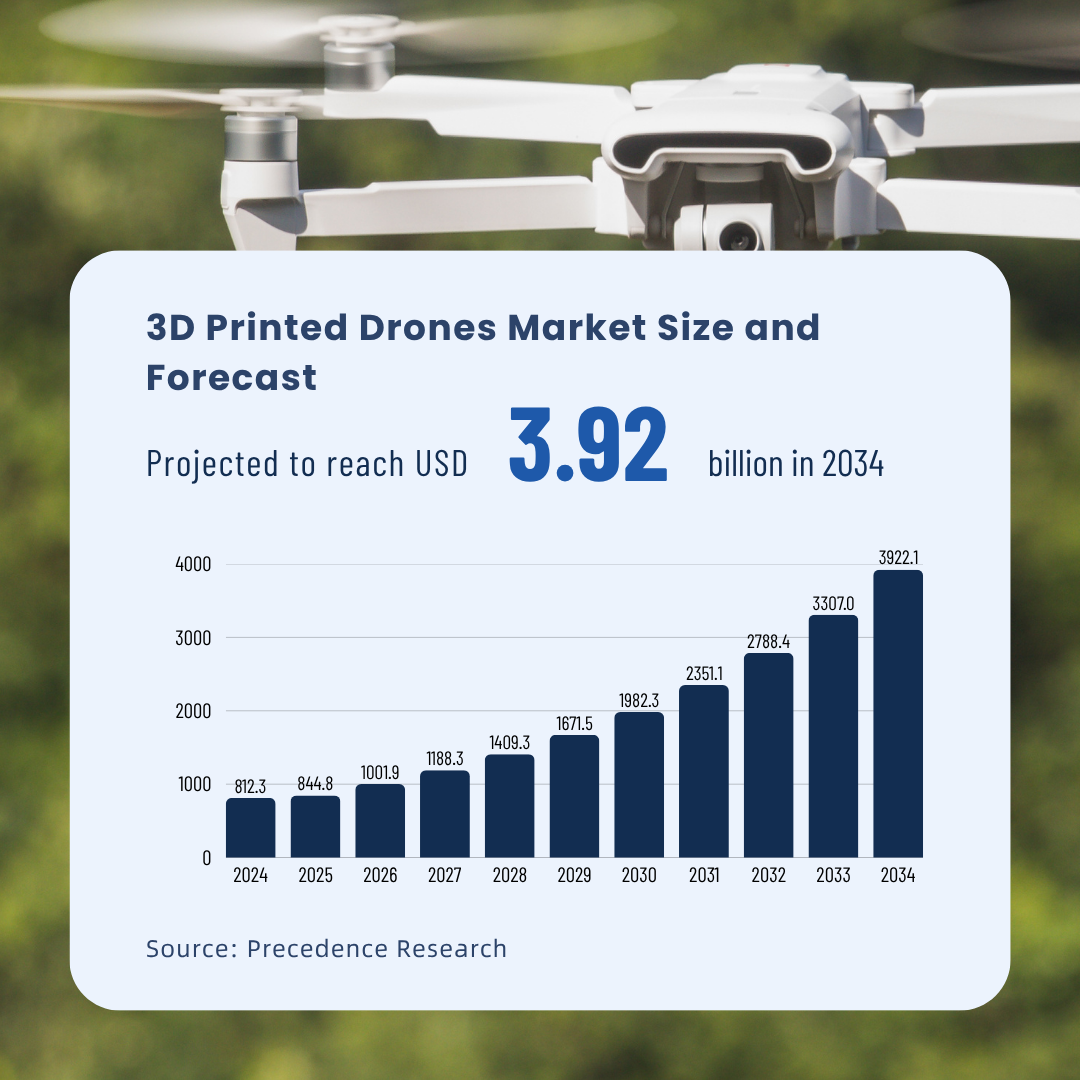

According to Precedence Research, the global market for 3D-printed drones is expected to grow from USD 812 million in 2024 to USD 3.92 billion by 2034, at a compound annual growth rate of 17.1%.

Why SLS Stands Out

A range of 3D printing technologies are used in UAV manufacturing today, including Powder Bed Fusion (PBF), Fused Deposition Modeling (FDM), and Continuous Fiber Reinforcement (CFR). SLS, a leading PBF method, has emerged as a preferred solution due to its advantages in Z-axis strength, build volume, surface finish, design flexibility, and cost efficiency. It allows for the production of complex structural parts without the need for support structures, minimizing post-processing and material waste.

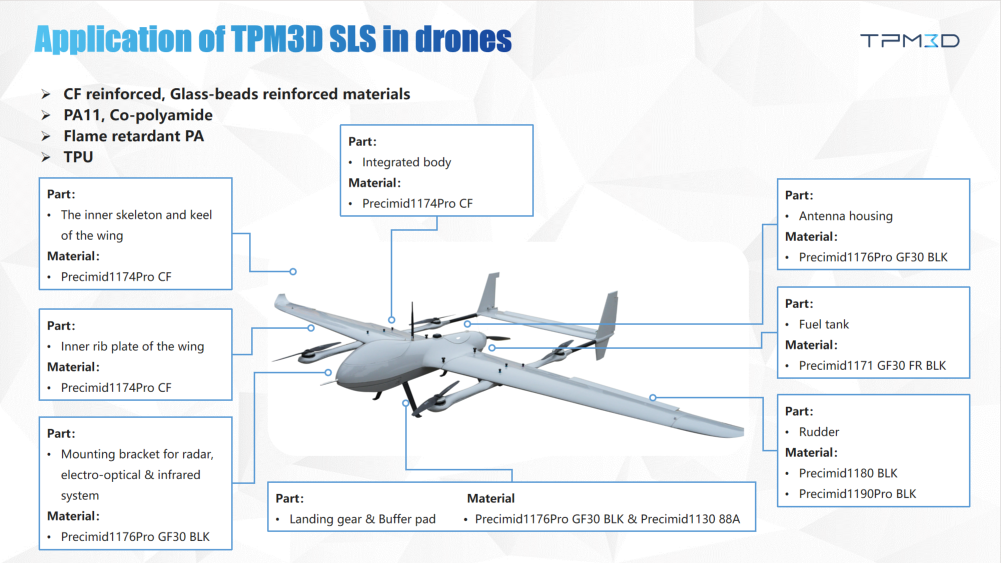

With over 20 years of expertise in SLS technology, TPM3D has built a full suite of 3D printing systems and high-performance materials. These include carbon fiber-reinforced and glass fiber-reinforced nylons for strength and rigidity, Nylon 11 and co-polyamides for impact resistance, and flame-retardant polymers for added safety.

These materials are suited for a variety of UAV components. In multirotor drones, they can be used for arms, battery holders, and propeller guards. In fixed-wing drones, they are applied in integrated fuselages, fuel tanks, and internal wing structures. TPM3D’s polymer powder materials and technology provide manufacturers with the flexibility to meet diverse performance demands.

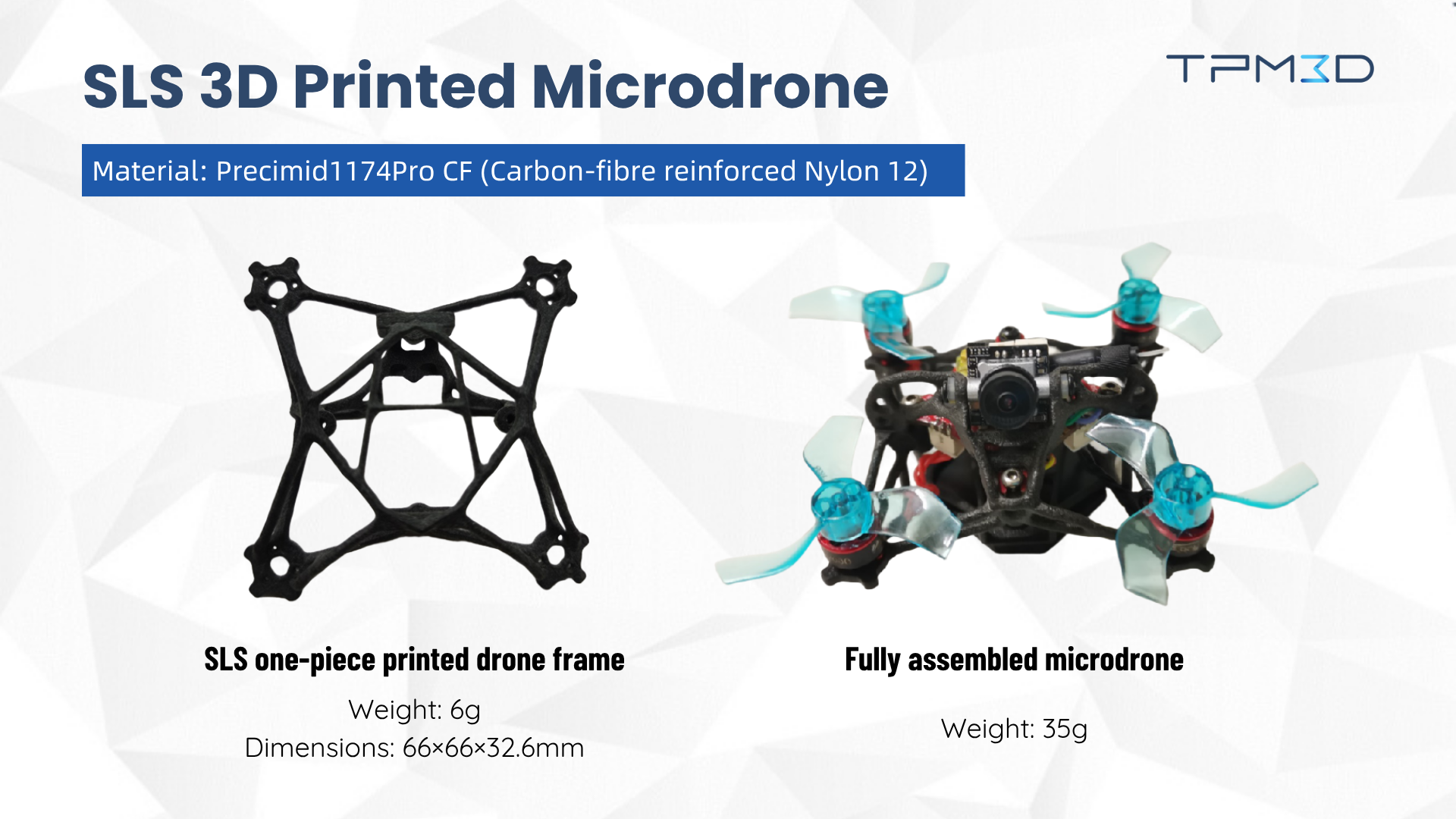

A 6-Gram Frame for Micro UAVs

In a recent showcase, TPM3D’s SLS technology enabled the production of a topology-optimized micro drone frame measuring 66 x 66 x 32.6 mm. Using Precimid1174Pro CF (a carbon fiber-reinforced Nylon 12), the frame was printed in one piece without support structures. Despite weighing only 6 grams, the frame maintains excellent structural rigidity. The fully assembled drone weighs just 35 grams—quiet, agile, and ideal for use in indoor flight, confined spaces, or light-payload missions.

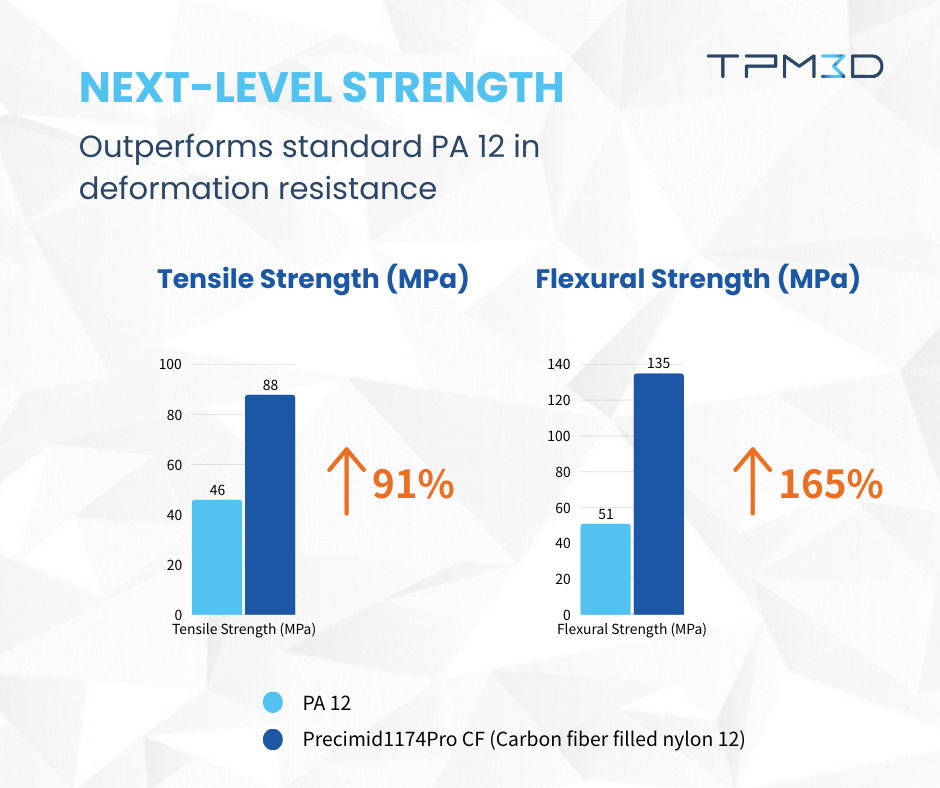

Compared to unfilled Nylon 12, the carbon fiber-reinforced version provides a 91% increase in tensile strength (88 MPa) and a 165% increase in flexural strength (135 MPa), along with greatly improved stiffness. This ensures excellent resistance to deformation and cracking during operation.

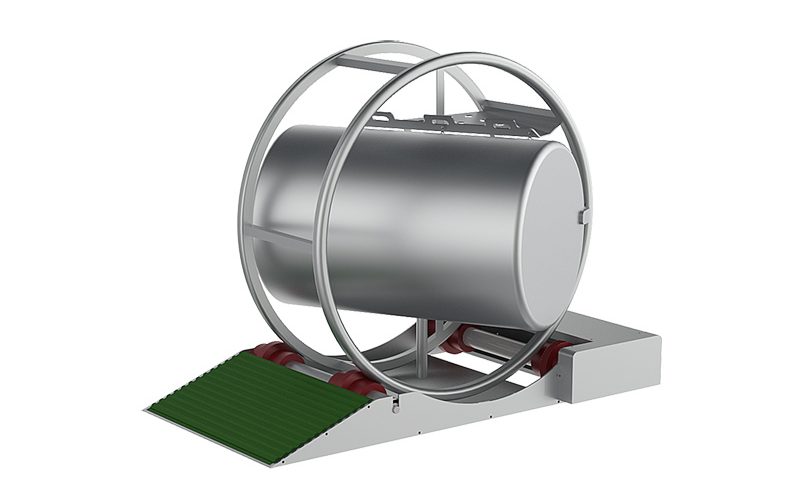

Tackling Structural Complexity in Quadcopter Production

In another project involving a quadcopter platform, TPM3D’s SLS solution was used to produce structural parts with highly complex geometries. The components featured thin walls, interlocking tabs, hole patterns, and snap-fit features—all of which are difficult to manufacture using traditional methods.

Due to the drone’s long-range and endurance requirements, both strength and weight were critical. TPM3D selected Precimid1176Pro GF30 BLK, a glass fiber-reinforced Nylon 12 material, to meet these needs. Printed via SLS, the components achieved a balance of stiffness and detail accuracy, ensuring both flight stability and mechanical resilience.

The printed parts underwent a full suite of real-world tests:

- Static load test: The components successfully supported heavy payloads without visible deformation or structural failure.

- High-low temperature cycle test: The parts maintained dimensional stability and mechanical performance under simulated extreme temperature conditions.

- Electromagnetic shielding test: The drone maintained stable communication in high-interference environments, showing no signal loss or control issues.

- Dynamic flight test: At flight speeds of 8 m/s with aggressive maneuvering, the printed components held up under continuous stress and vibration, confirming their readiness for demanding UAV missions.

Supporting the Next Generation of UAVs

As drones become more advanced, the ability to quickly produce strong, lightweight, and complex parts will be essential. TPM3D’s long-standing investment in SLS printing systems and materials R&D makes it a trusted partner for drone manufacturers seeking faster development cycles, better performance, and lower production risk.