As additive manufacturing continues to transform modern industries, the demand for high-performance, flame-retardant 3D printing materials has grown significantly. TPM3D developed Precidim1171 FR BLK, a flame-retardant nylon 12 material engineered for applications in electronics, automotive, and aerospace sectors. Combining excellent mechanical properties, heat and wear resistance, and UL94 V-0 flame retardancy (verified through SGS vertical combustion testing), this material opens new possibilities for safer and more efficient production.

Flame-Retardant 3D Printing in Electronics

In the electronics sector, low-voltage appliances require components with high flame resistance to ensure product safety. Precimid1171 FR BLK has been tested on 3D-printed circuit breakers, undergoing arc extinguishing trials at 16,000A for 5 seconds with flame exposure and temperatures exceeding 1000°C. The material successfully suppressed combustion while maintaining structural integrity.

Beyond safety, using SLS 3D printing with this material reduces production costs and lead times. Compared to conventional CNC machining or mold-based processes, 3D printing reduces part costs by approximately 82.5%, with components produced within 48 hours, cutting production time by 60%. This allows manufacturers to improve efficiency, reduce costs, and enhance product quality.

Applications in Electric Vehicles

Flame retardancy is critical in electric vehicles (EVs), particularly for components like battery modules, electrical wiring, and interior/exterior parts. As battery fires have emerged as a safety concern, Precimid1171 FR BLK offers an ideal solution.

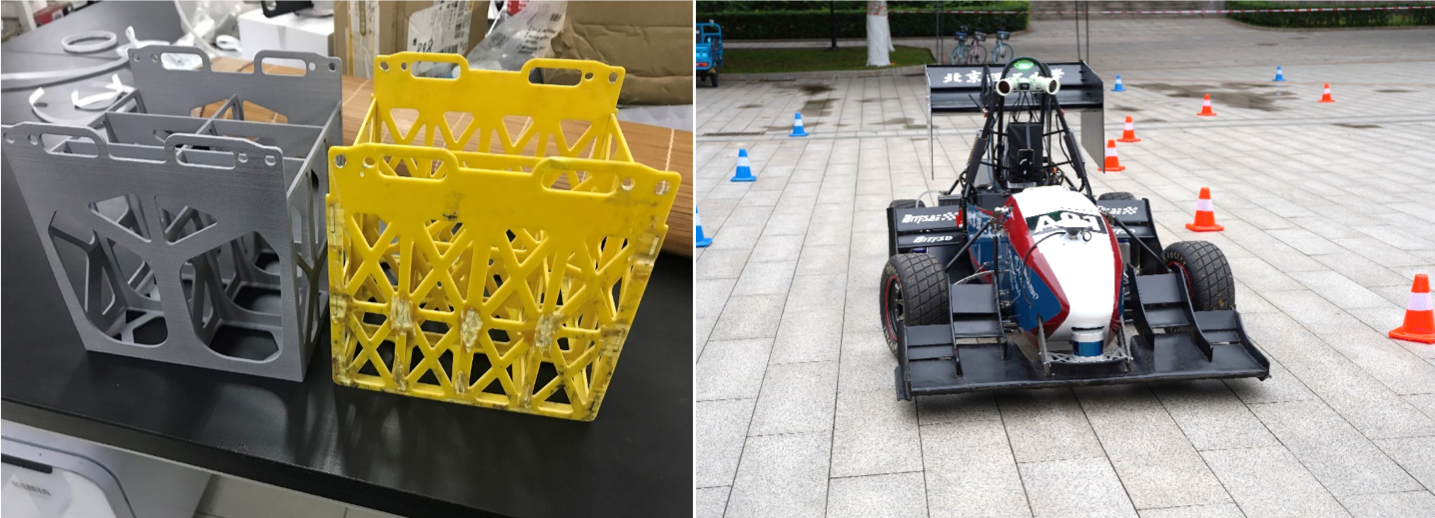

TPM3D has applied this material in racing teams at Beijing Institute of Technology and Tongji University, producing flame-retardant battery module frames. These frames act as barriers, slowing the spread of combustion during battery thermal runaway, while also reducing weight and improving performance. Although flame-retardant 3D printing is still emerging in the EV sector, its potential for safety enhancement and lightweight design is considerable.

Expanding Possibilities Across Industries

Precidim1171 FR BLK’s combination of flame retardancy, mechanical strength, and thermal and wear resistance makes it suitable for diverse industries, from electronics and automotive to aerospace. As 3D printing technologies continue to evolve, flame-retardant materials like Precimid1171 FR BLK are expected to expand their applications, offering safer, faster, and more efficient solutions for modern manufacturing challenges.