Compact Fiber 200 + PPS 200: Clean, Compact Professional SLS 3D Printer

Seamlessly integrate professional-grade SLS performance, versatility, and precision into your R&D lab or office environment—without the dust and complexity.

Compact Footprint

Total System Size < 1m2

Ease of Use

Standard 220V Plug-and-Print Operation

Clean Workflow

Fully Enclosed Powder Management

CF200 Specifications

| Specifications | CF200 |

| Laser | 30W Fiber Laser |

| Focus | F-θ Field Lens |

| Build Chamber Size (X×Y×Z) | 200×200×320 mm |

| Layer Height | 0.1 mm |

| Print Speed | 0.5-0.8 L/h* |

| Powder Supply Bin Volume | 15 L |

| Powder Supply and Recoater | Right Side Top Feed, Dual Side Recoating |

| Material | PA11, PA12, PA12 GF, PA12 CF, TPU |

| Virgin Powder Ratio | 20-40% |

| Powder Particle Diameter | 20-60 μm (Recommended) |

| Working Temperature | 18-28 °C |

| Humidity Requirements | 20-50% RH |

| N₂ Protection | Optional |

| Security Standard | CE |

| Dimensions (L×W×H) | 700×625×1350 mm |

| Weight | 130 kg |

| Power | 220V AC / 50Hz |

| Pedestal Dimensions (L×W×H) | 720×645×335 mm |

| Pedestal Weight | 16 kg |

* Print speed is influenced by many factors including packing density, material type, part structure etc.

PPS200 Specifications

| Specifications | PPS200 |

| Auto-Depowdering | Yes, via Rotating Basket |

| Basket Rotation Speed | 60-80 rpm |

| Auto-Sieving | Yes |

| Sieve Vibration Force | 55 kg |

| Auto Powder Mixing | Yes |

| Rotation Speed Mixer | 120 rpm |

| Mixer Volume | 16 L |

| Auto Powder Supply | Yes |

| Powder Supply Method | Automatically Supplied via Pipelines |

| Dust Suppression | Negative Pressure Dust Collection System |

| Safety Standard | CE |

| Operation Screen | 10″Touchscreen,1080P Resolution |

| Dimensions | 700×800×1685 mm |

| Weight | 160 kg |

| Power | 220V AC / 50Hz |

| Printers Supported | Numerous ** |

* The PPS200 can dynamically support the depowdering work and powder supply for multiple printers, the max number of printers is influenced by the management of print jobs.

Key Features Explained

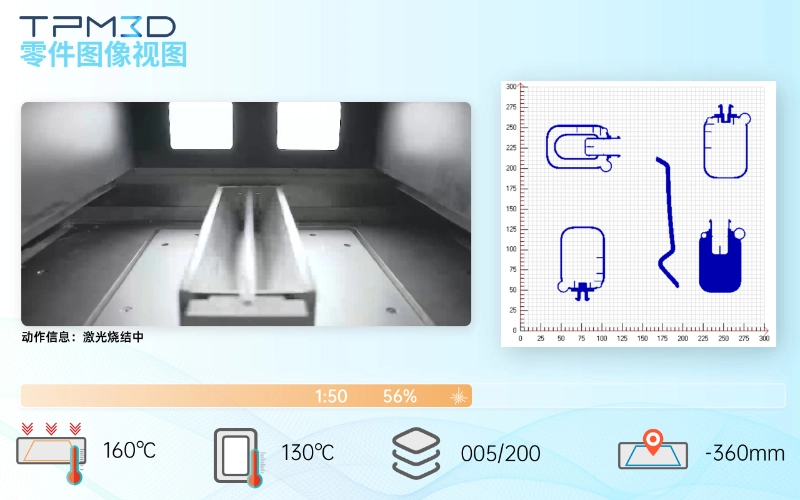

This video offers a clear, concise introduction to the core design and performance advantages of the TPM3D CF200 + PPS200 system. See how its compact footprint, intelligent operation, and closed-loop powder management work together to solve common SLS challenges—from large space demands to complicated workflows and dust-control issues.

SOLVING COMMON SLS CHALLENGES

The Problem

TPM3D Compact Series Solution

Large Footprint & Space Constraints

Compact Design (<1 sqm total system)

Complex Operation & Learning Curve

Plug-and-Play (220V) & One-Click Start

Powder Dust & Contamination

Clean, Enclosed Workflow (PPS200)

STANDARD 220V: PLUG-AND-PRINT SLS

The Compact Fiber 200 (CF200) + PPS200 system requires only a standard 220V power input, allowing users to power on anytime without needing dedicated high-voltage industrial lines.

This plug-and-play capability streamlines installation, lowers infrastructure costs, and supports better sustainability efforts through lower energy consumption and a reduction in the system’s overall carbon footprint.

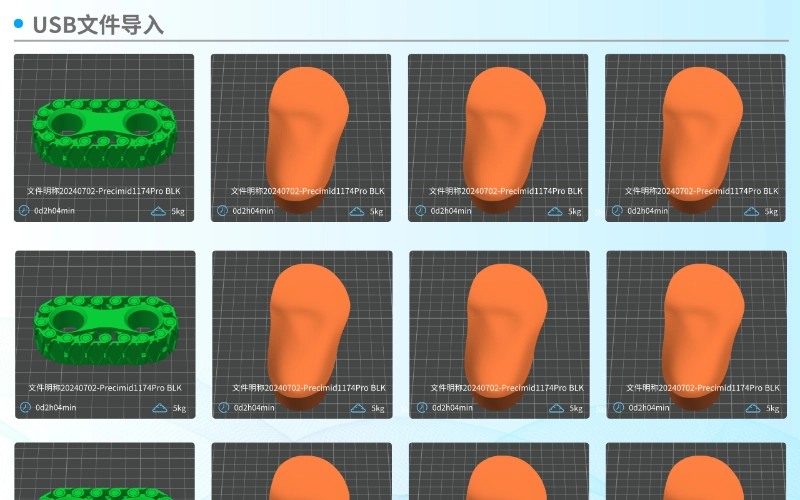

ONE-CLICK PRINTING FOR RAPID R&D

Designed for speed and simplicity, the CF200 eliminates complex setup and operational bottlenecks:

Simple Operation

Quick Import, Quick Start

User-Friendly Software

DUST-FREE, POLLUTIONLESS POWDER MANAGEMENT

The PPS200 station delivers a paradigm shift in SLS cleanliness by implementing a closed process with no direct powder contact required.

The system performs fully automated depowdering, sieving, mixing, and feeding the prepared powder back to the CF200 printer through a pipe.

The powder cake is removed in an enclosed box and cleanly transferred to the PPS200.

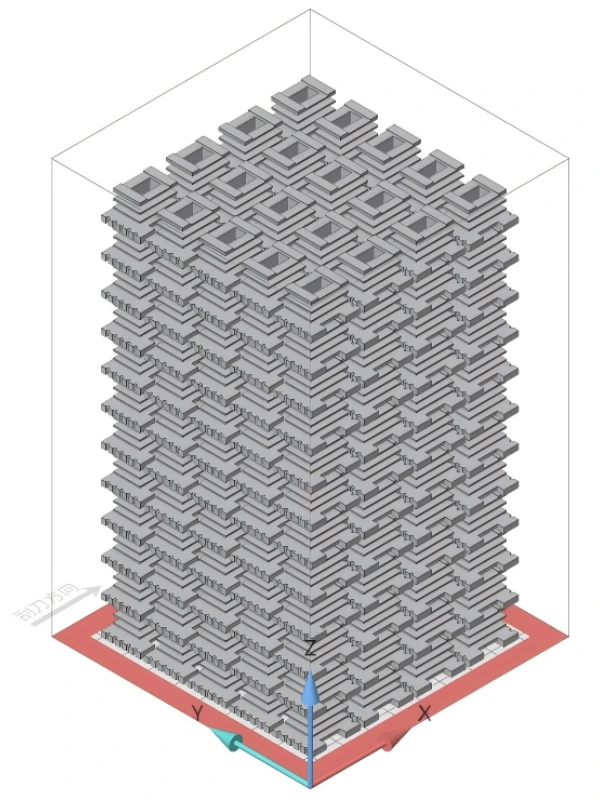

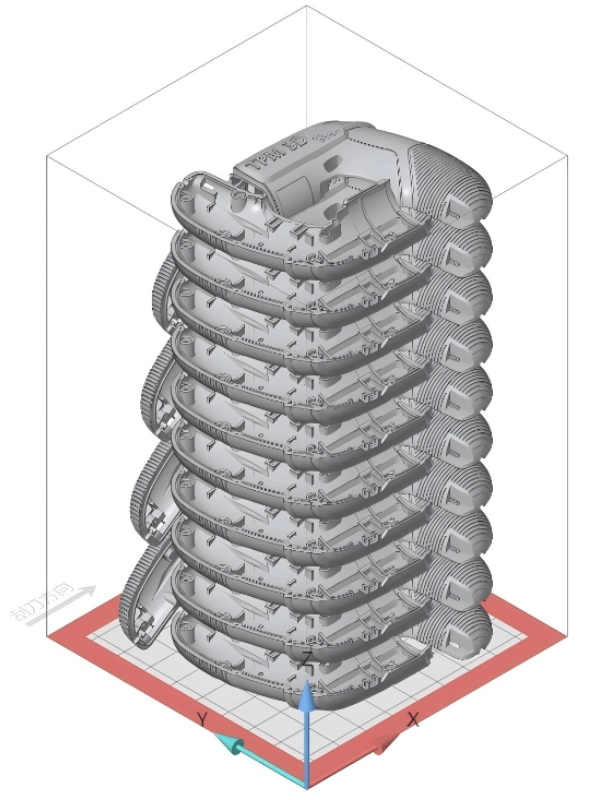

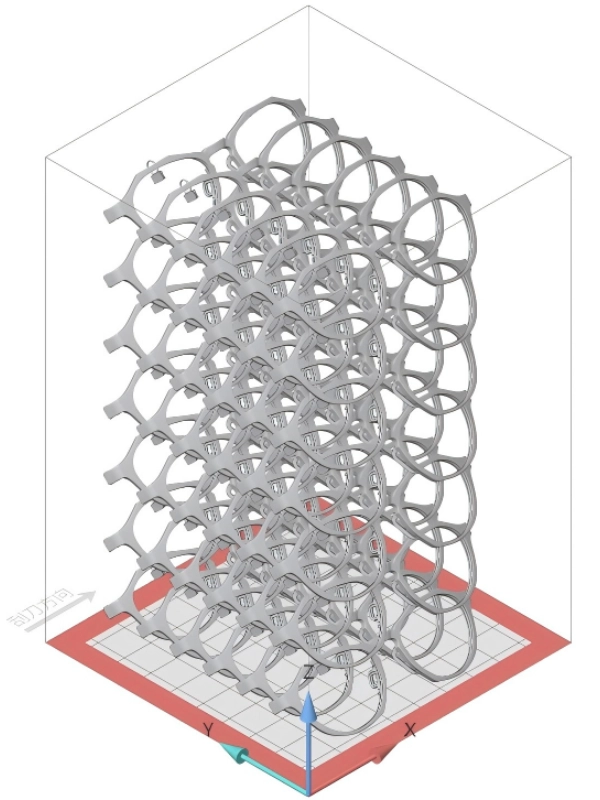

MAXIMIZE OUTPUT IN A SINGLE BUILD

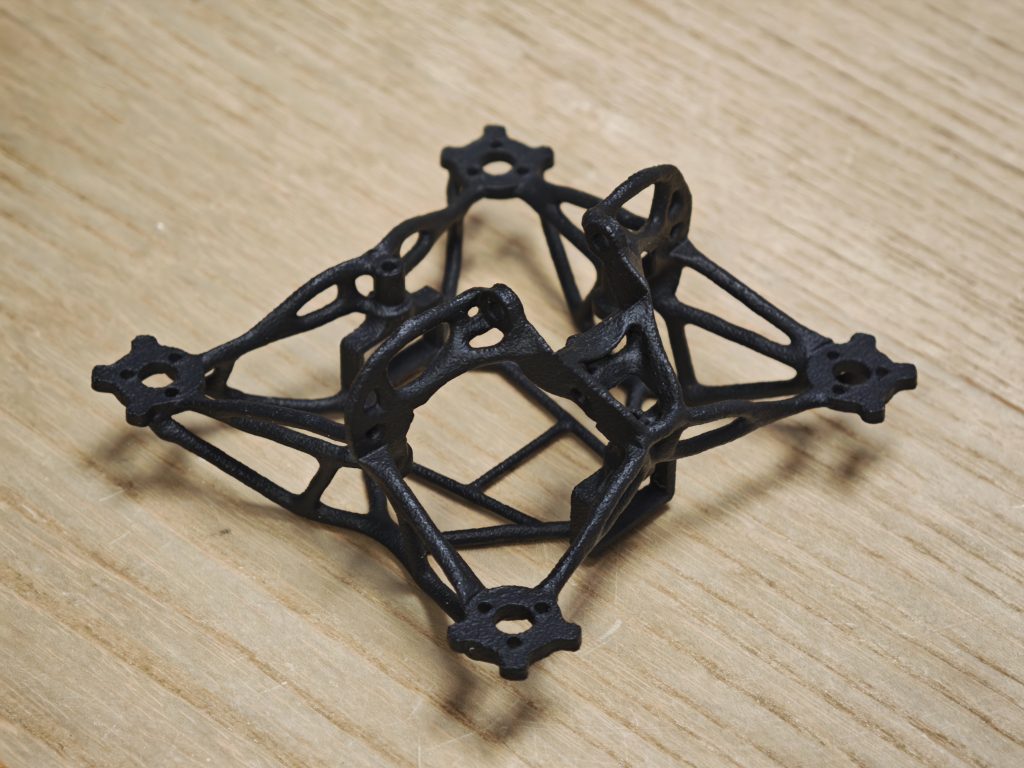

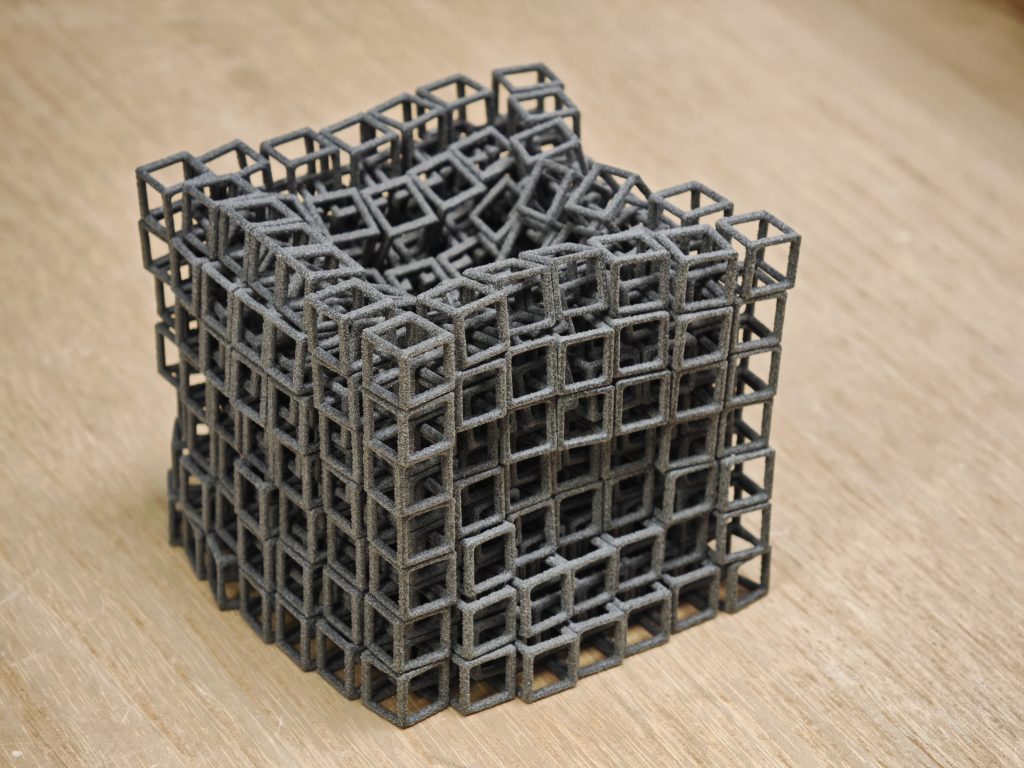

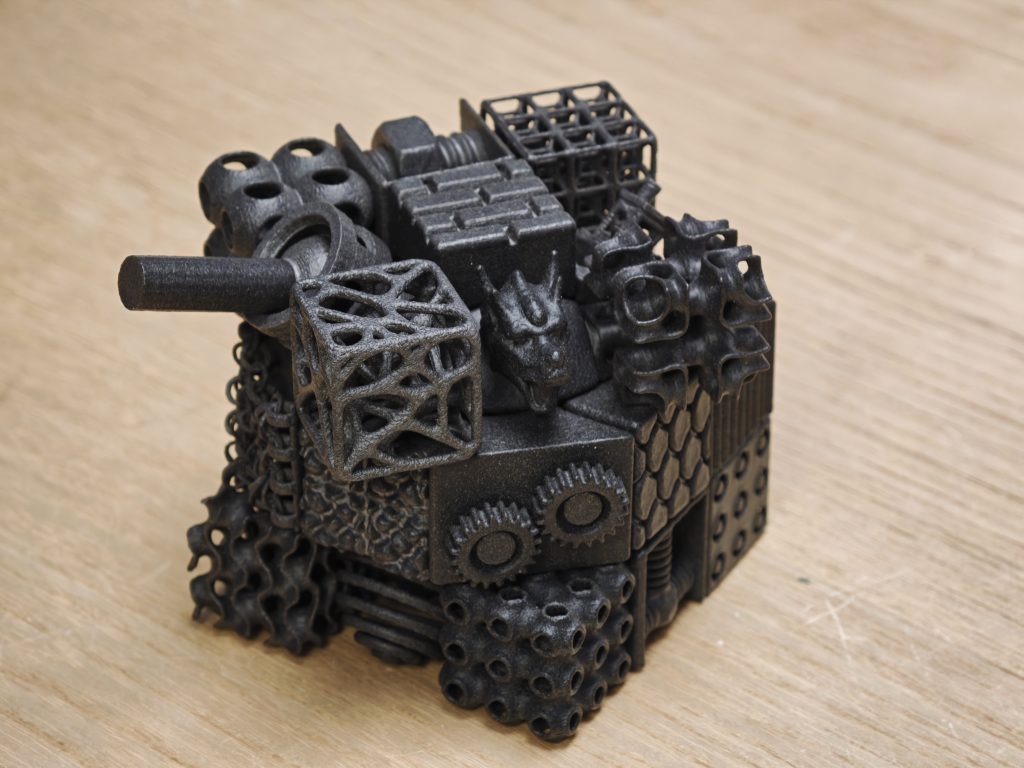

The CF200 printer delivers the capacity required for rapid iteration and efficient small-batch runs within its compact frame. The 200 x 200 x 320 mm build chamber provides high-volume density, enabling efficient production within one build, making parts ready for same-day delivery.

A single build job is capable of producing:

240 coil windings

12 sets of electric tool handle housings

42 pairs of 3D printed eyeglasses frames

MATEIRAL ECOSYSTEM

Unlock a wide range of engineering applications with high-performance SLS powders

PA11

High impact resistance, high ductility, heat resistant. Ideal for prototypes, medical devices, and more.

PA12

Stable color, accurate dimensions, balanced mechanical performance. Perfect for structural parts, functional shells, complex assemblies, and more.

TPU

High impact resistance, high ductility, heat resistant. Ideal for prototypes, medical devices, and more.

INDUSTRIAL-GRADE RESULTS

- Dimensional accuracy

- Superior part consistency

- Robust mechanical properties

- Broad material support

INDUSTRY APPLICATIONS: R&D TO SMALL-BATCH PRODUCTION

Unlock new possibilities across industries with high-quality, on-demand parts

R&D Departments

Clean, high-precision prototyping and rapid design

Small-Batch Manufacturing

Versatile, reliable, and cost-effective short-run production

Research Labs/Universities

Safety, ease of use, and broad material support

Design Workshops

Empowers design freedom