Personalized solutions are reshaping modern healthcare, offering patients better outcomes and improved quality of life. As one of the key enablers of this trend, 3D printing is empowering the medical industry with tools for flexible, customized production. TPM3D, a global leader in SLS 3D printing, is at the forefront—helping medical companies worldwide shift from traditional workflows to digital, patient-specific manufacturing.

One such success story comes from Edser, a leading Spanish orthotics and insole manufacturer. Through its collaboration with TPM3D, Edser has integrated SLS 3D printing into its product lines, enhancing both product quality and manufacturing efficiency.

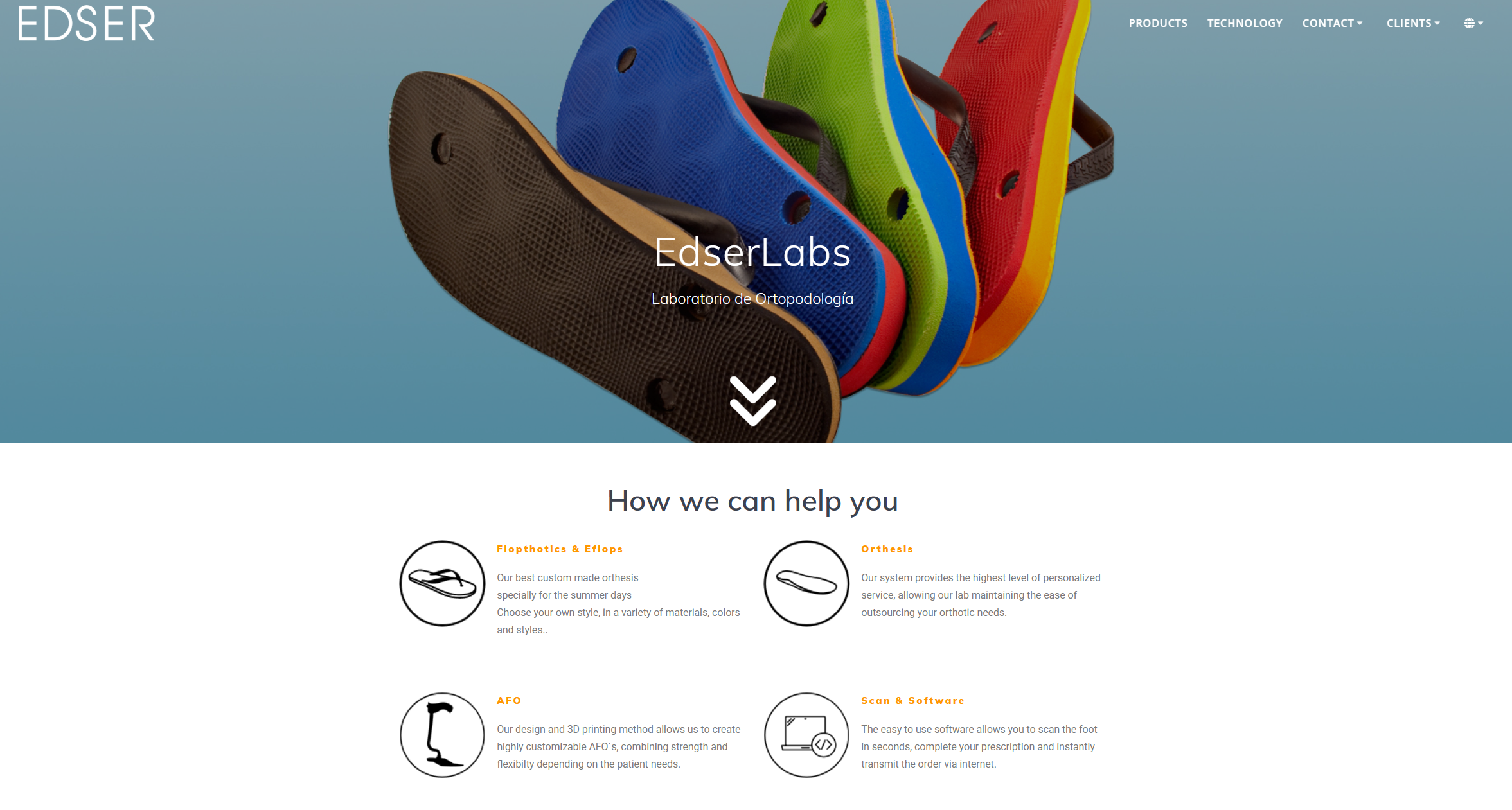

Edser: A Custom Orthotics Pioneer with a Global Footprint

With nearly three decades of experience in clinical and lab-based orthotic design, Edser specializes in producing high-quality, custom-made orthotic insoles and braces. Headquartered in Spain, the company operates more than 10 regional offices across major cities such as Barcelona, London, Dubai, New York, Miami, and Oslo.

Screenshot of Edser’s website

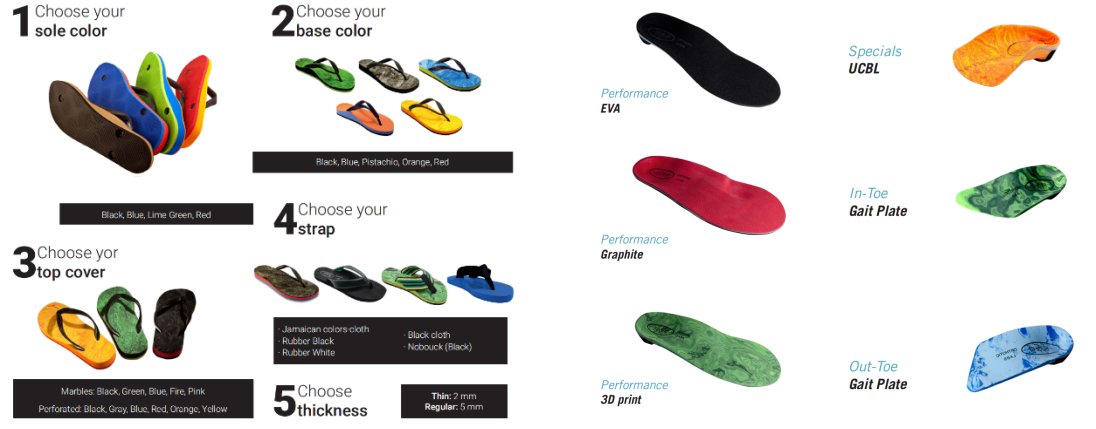

Edser’s product range includes:

- Custom orthotic insoles

- Stylish yet functional sandals

- Orthotic braces (e.g., scoliosis and ankle-foot orthoses)

- Sports protection gear (e.g., shin guards, facial masks)

Its commitment to innovation and global service has earned Edser a strong reputation in the field of medical orthotics.

Sandals and insoles designed by Edser

From Foot Scan to Finished Product in 4 Days: How SLS Streamlined Edser’s Workflow

To meet growing demand for custom-fit solutions, Edser turned to TPM3D’s SLS 3D printing technology to upgrade its manufacturing process. Key products made with SLS include:

- Orthotic insoles

- Custom sandals

- Scoliosis braces

- Ankle-foot orthoses (AFOs)

- Protective face masks

Edser’s insole offerings are especially diverse, featuring collections tailored for fashion-conscious women, athletes, general users, and patients with specific conditions like diabetes or flat feet.

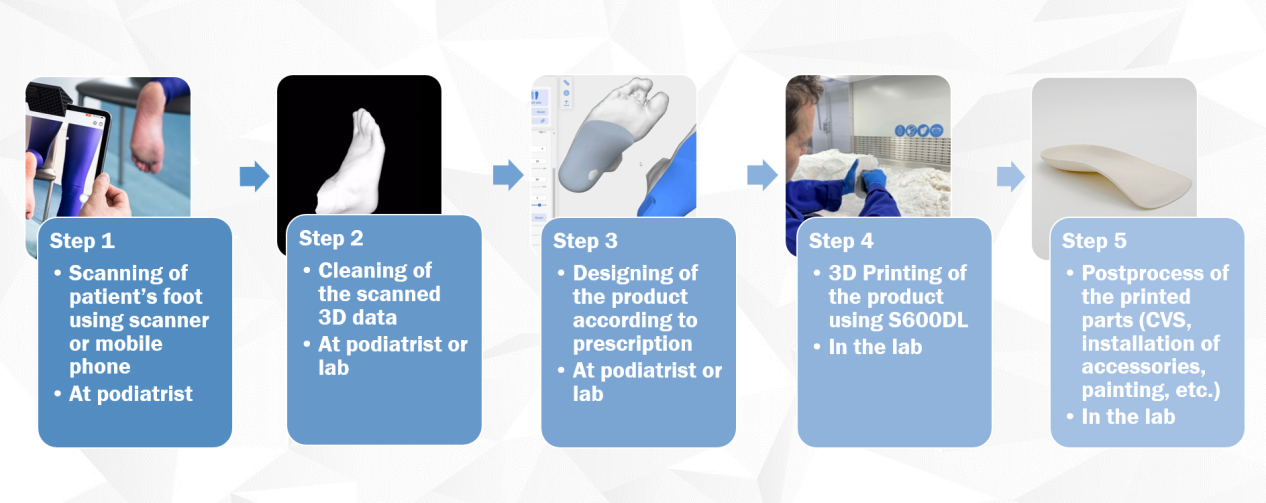

To further simplify the customization process, Edser developed its own scanning and design app. Using LiDAR-equipped devices like iPhones and iPads, patients can easily scan their feet—no professional scanner required. The entire workflow consists of:

- Foot scan (by the customer)

- 3D data processing

- Design modifications based on medical input

- SLS 3D printing

- Post-processing

The result? Custom-fit insoles delivered in as little as four days, with minimal barriers to entry for clinics or users.

Edser’s Workflow

Why SLS Is a Perfect Fit for Edser’s Needs

Given Edser’s highly customized, short-turnaround production model, SLS is the ideal solution. By working with TPM3D, Edser benefits from advanced technology, top-tier materials, and expert support.

To meet its growing output demands, Edser selected the TPM3D S600DL, a flagship dual-laser SLS printer with a large build volume (600 × 600 × 800 mm). The machine is built to the highest EU safety standards and TÜV CE certified. Key features include:

- Dual 140W lasers and high-precision dynamic focusing

- Up to 2×22m/s scan speeds for faster throughput

- Proprietary dual-laser coordination algorithm for optimal print quality

In addition, TPM3D’s Powder Post-Processing Station (PPS) streamlines the entire post-print workflow—handling depowdering, dust suppression, powder recovery and mixing, and real-time feeding. This is especially valuable for Edser’s batch production needs, saving labor and maintaining a clean, efficient workspace.

S600DL and PPS Station installed at Edser Lab in Barcelona

Powered by TPM3D PP Pro: Strong, Flexible, and Cost-Efficient

For material, Edser uses TPM3D PP Pro, known for its:

- Excellent strength and chemical resistance

- Low water absorption and lightweight properties

- Ability to be reshaped with heat after printing—ideal for making comfort adjustments

PP Pro also enables highly sustainable production, requiring just 20% virgin powder in each batch. With smart nesting and print planning, material utilization can approach 100%, minimizing waste and reducing cost.

Orthotics printed with S600DL by Edser

S600DL in Action at Edser’s Barcelona Lab

With TPM3D’s technology in place, Edser has achieved:

1. Increased Capacity & Efficiency

The S600DL’s large build volume allows for more parts per run—both large items and small batches—while dual-laser scanning cuts layer time nearly in half. This has translated to an approximate 45% improvement in overall efficiency.

2. Faster Product Development

New insole or brace designs can be quickly printed and tested, enabling faster iterations and a shorter path to market.

3. Enhanced Product Design & Performance

SLS printing supports complex geometries like hollow structures, lattices, and textures—without support material. For insoles, lattice structures allow Edser to fine-tune hardness across zones while keeping the product breathable and lightweight.

4. Lower Production Costs

The S600DL offers best-in-class ROI, especially when paired with TPM3D’s high-yield PP Pro material and efficient powder management system.

5. Higher Customer Satisfaction

The end products—especially insoles—fit precisely to each patient’s foot shape, offering superior comfort and therapeutic performance. Despite running near full production capacity last year, Edser reported virtually zero customer complaints, with consistently positive feedback from clinics and end users alike.

A Win-Win Collaboration for Smarter Medical Manufacturing

Through its strategic partnership with TPM3D, Edser has upgraded to high-volume, high-precision custom manufacturing. By leveraging SLS 3D printing, they’re delivering better products faster—and more cost-effectively—while enhancing user satisfaction.

As SLS technology continues to evolve, Edser and TPM3D look forward to driving further innovation in digital orthotic manufacturing, bringing better care to more patients around the world.