PEEK (polyetheretherketone) is an aromatic crystalline thermoplastic polymer with a melting point above 300 °C. It offers high mechanical strength, heat resistance, impact resistance, flame retardancy, chemical resistance, wear resistance, fatigue resistance, and excellent electrical properties. These characteristics make it ideal for high-end applications in industrial, military, medical, and motorsport sectors.

For 3D printing, PEEK can be processed using SLS or FDM technology. While SLS is more expensive, it offers greater conformity with high-end manufacturing requirements and fewer limitations in molding complex geometries. Below, we explore a practical case study to understand its application.

Case Study: SLS PEEK Printing in Germany

A German company experimented with commercial SLS printing of PEEK. Due to software limitations, they could only use a single PEEK material, which restricted research and experimental flexibility. Their goal was to explore material possibilities for research institutions in Russia and beyond.

The conceptual design of the SLS printer included the following performance requirements:

-

Molding size: 500 × 500 × 300 mm

-

Compatibility with multiple PEEK materials

-

Preheated powder layer: 385 °C ±2 °C

-

Nitrogen protection concentration: 99.8%

-

Accuracy: ±10 μm

-

Slow cooling capability for the silo body

-

Laser sintering methods: Gaussian transform, inverse Gaussian transform, etc.

-

Heat-resistant fuselage, galvanometer, and other components

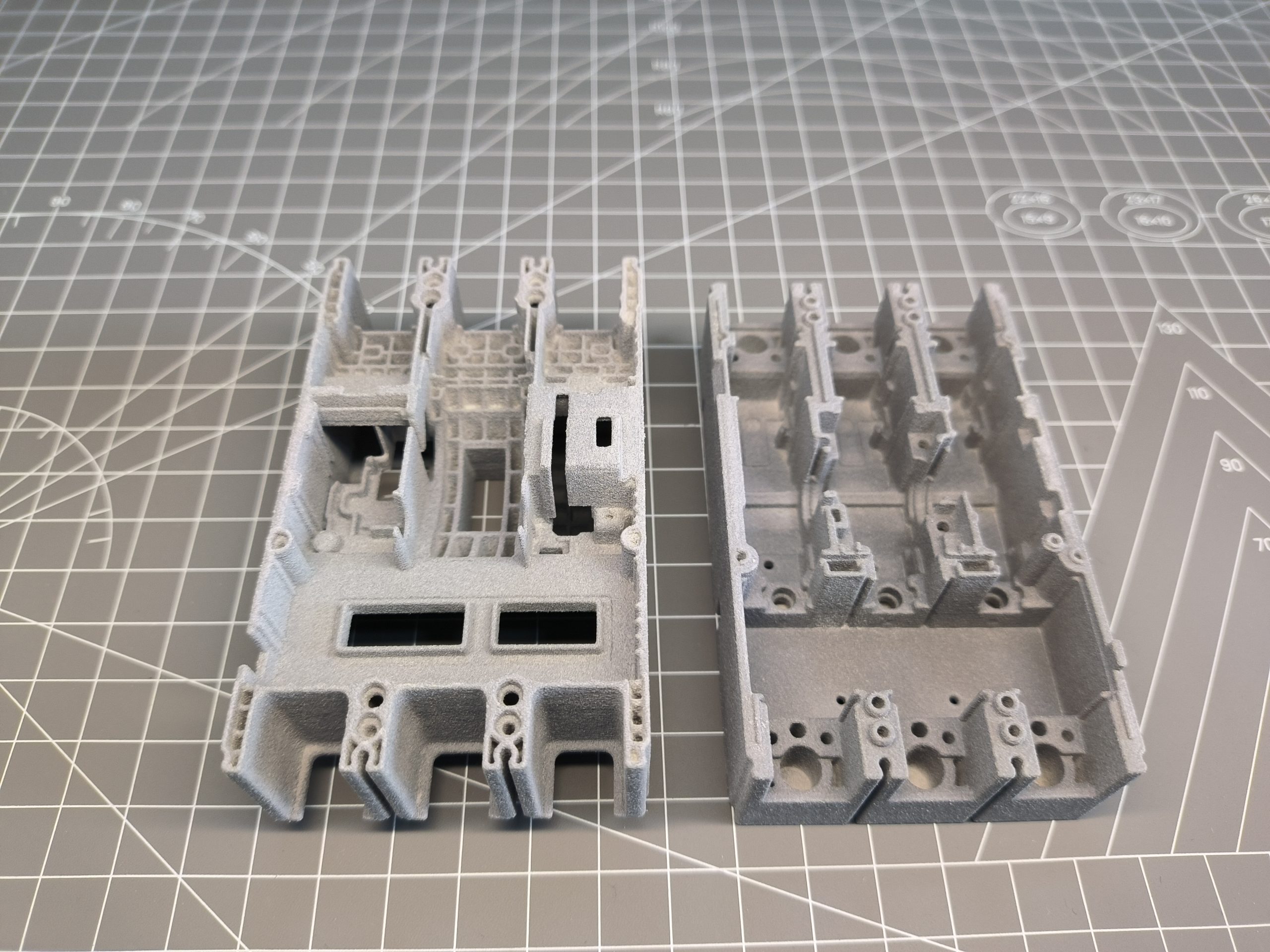

After several revisions, the final prototype met the design requirements.

Innovations in SLS Printer Design

The prototype featured servo motor-controlled threaded screw rods for platform lifting, replacing traditional belt-driven systems. This approach improves precision and reliability and is similar to the mainstream solutions of TPM3D in China, which also employs double-sided scraper powder spreading to increase efficiency.

The optical path and sintering methods were also carefully designed. An 80 W laser source allows Gaussian, top-hat, and reverse Gaussian sintering, providing flexibility for different crystalline phase sintering.

Testing and Results

Initial prints demonstrated that the new design reliably handled multi-thermal field settings, proving the feasibility of the structure and process. While other manufacturers’ equipment may not yet reach this performance, this case study provides a strong platform for future refinement and innovation.

Currently, TPM3D’s high-temperature SLS models, such as the S320HT, have overcome these technical challenges, meeting the above design requirements and producing successful PEEK prototypes and personalized parts.

PEEK 3D Printed Parts by TPM3D

The high-temperature SLS technology enables customized, high-performance PEEK components suitable for industrial, medical, and specialized applications, demonstrating the practical potential of SLS for advanced thermoplastics.