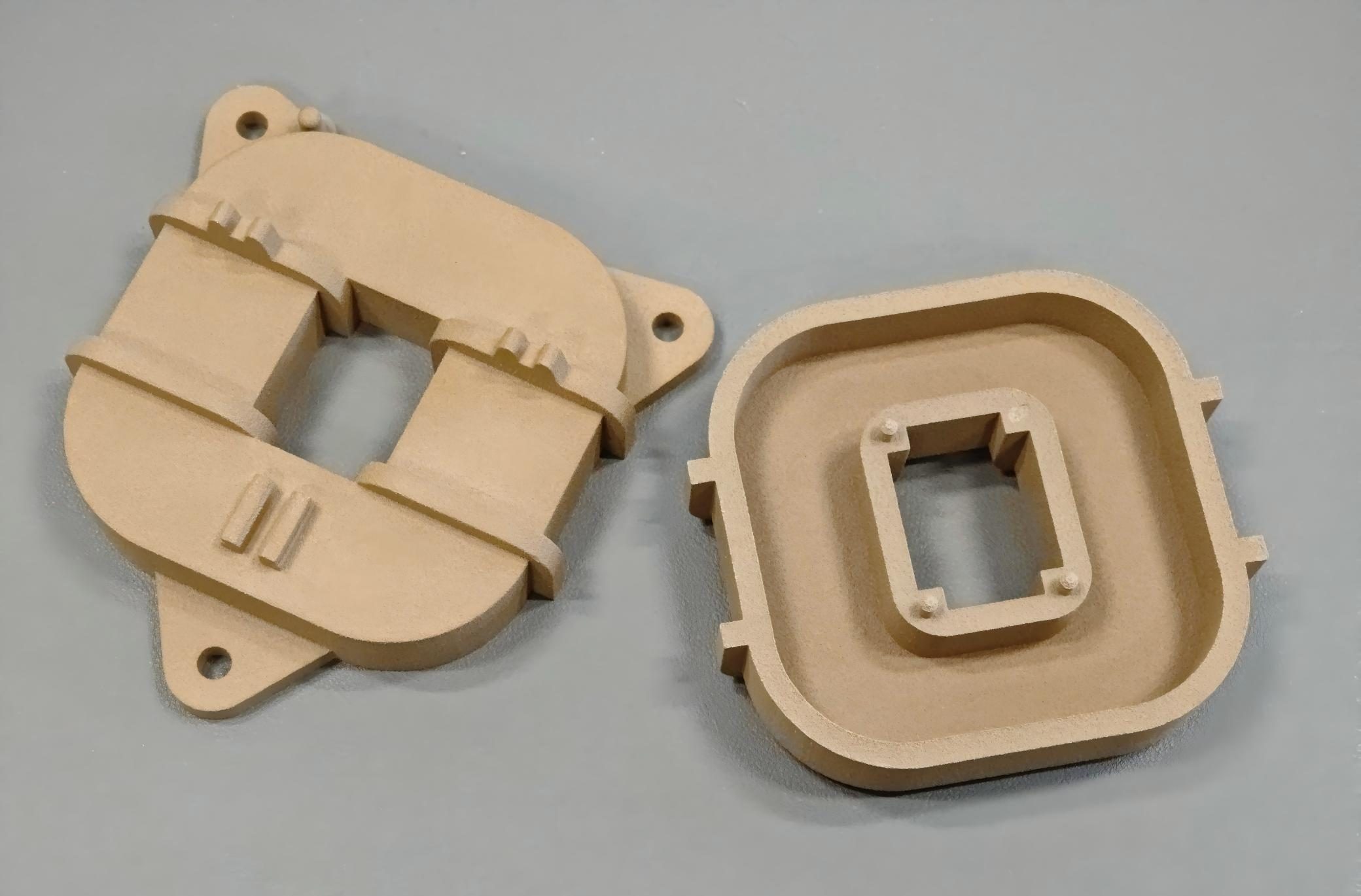

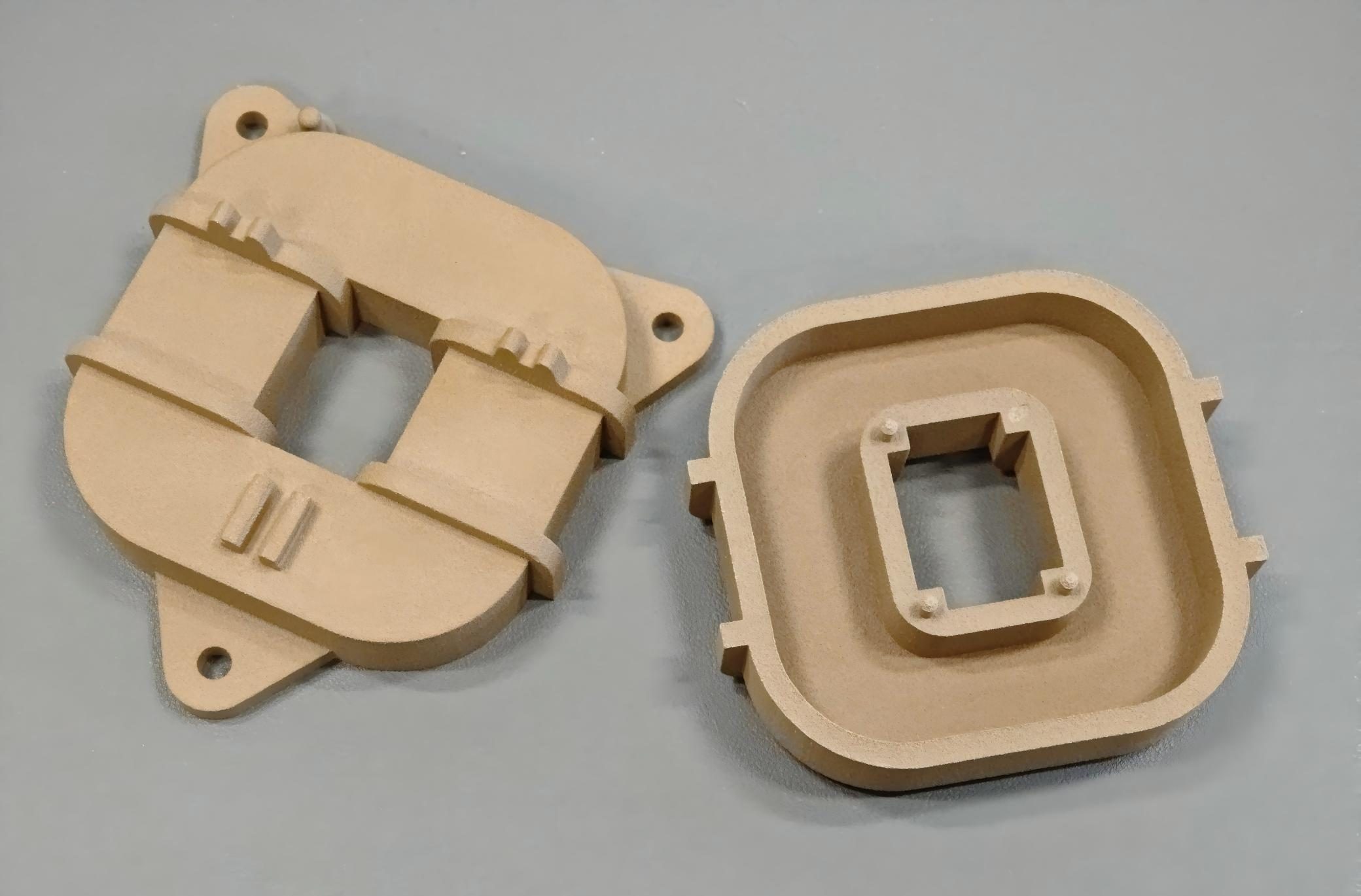

TPM3D PPS IND is a high-performance polyphenylene sulphide (PPS) material developed for SLS 3D printing. This PPS plastic material offers high stiffness, flame retardancy, and stable chemical properties, making it suitable for demanding industrial and engineering applications. With thermal stability and biocompatibility, it’s an ideal solution for sectors such as electrical manufacturing, mechanical parts, etc.

| Mechanical properties | Test method | Metric |

| Part Color | Visual | Yellowish Black |

| Elongation at break | ISO 527 | 2.7% |

| Tensile Strength (MPa) | ISO 527 | 55 Mpa |

| Tensile Modulus (MPa) | ISO 527 | 3,900 Mpa |

| Flexural Strength (MPa) | ISO 178 | 70 Mpa |

| Flexural Modulus (MPa) | ISO 178 | 3,100 MPa |

| Single Notch Impact Resistance (KJ/m2) | ISO 180 | 1.4 KJ/m2 |

| Double Notch Impact (KJ/m2) | ISO 180 | 1.688 KJ/m2 |

| Thermal Deformation Temperature (°C) | >200°C |

TPM3D PPS IND delivers stiffness, chemical resistance, and heat tolerance for demanding manufacturing needs.

TPM3D PPS IND serves industries requiring reliable PPS plastic material and high-performance polyphenylene sulphide parts:

TPM3D PPS IND is engineered for TPM3D’s S320HT, providing consistent performance for both prototypes and end-use parts. It ensures stable dimensions and uniform surface finish across production runs.