TPM3D PP Pro | White Polypropylene

PP Pro is a polypropylene-based SLS material designed for PP 3D printing, offering low density, light weight, and minimal water absorption. Ideal for 3D printing polypropylene parts, it delivers a balance of mechanical performance and chemical resistance, making it well-suited for functional components in medical, automotive, consumer electronics, and fluid-handling applications.

- Low Density & Lightweight: At 0.80 g/cm³, ideal for reducing part weight without compromising functionality.

- Low Water Absorption: Maintains mechanical stability in humid or wet environments.

- Good Mechanical Balance: Sufficient strength, flexibility, and impact resistance for a wide range of applications.

- Chemical Resistance: Resistant to a variety of industrial fluids and solvents.

TPM3D PP Pro Specifications

| Mechanical properties | Test method | Metric |

| Part Color | Visual | Natural White |

| Density | ISO1183-1:2019:A | 0.80 g/cm³ |

| Elongation at break | ISO 527-1:2012 | 18.0% |

| Flexural strength | ISO 178:2019 | 30.2 MPa |

| Flexural modulus | ISO 178:2019 | 1,100 MPa |

| Heart Deflection temperature 0.45MPa | ISO 75-1:2013 | 98 ℃ |

| Heart Deflection temperature 1.82MPa | ISO 75-1:2020 | 64 ℃ |

| Tensile strength | ISO 527-1:2019 | 21.1 MPa |

| Tensile modulus | ISO 527-1:2019 & ISO 527-1:2012 |

1,180 MPa |

| IZOD impact strength with notch | ISO 180:2019 | 4.5 kJ/m² |

| IZOD impact strength without notch | ISO 180:2019 | 21 kJ/m² |

Looking for a lightweight, water-resistant material?

PP Pro combines low density and moisture resistance for versatile industrial use.

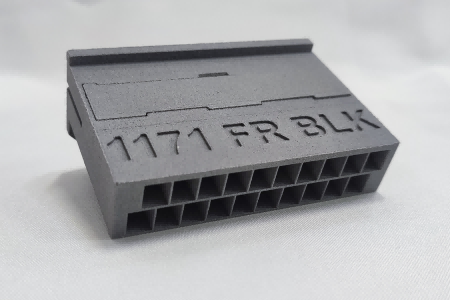

TPM3D PP Pro Applications

PP Pro supports 3D printing of PP parts that need durability, low moisture uptake, and reduced weight. It is used in:

- Medical Devices

- Orthotics (spinal brace, ankle-foot orthosis, and more)

- Automotive

- Consumer Electronics

- Fluid Containers

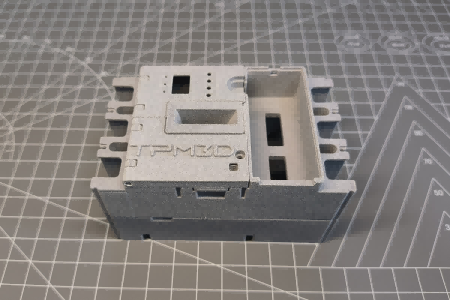

Seamless Compatibility with TPM3D's 3D Printers

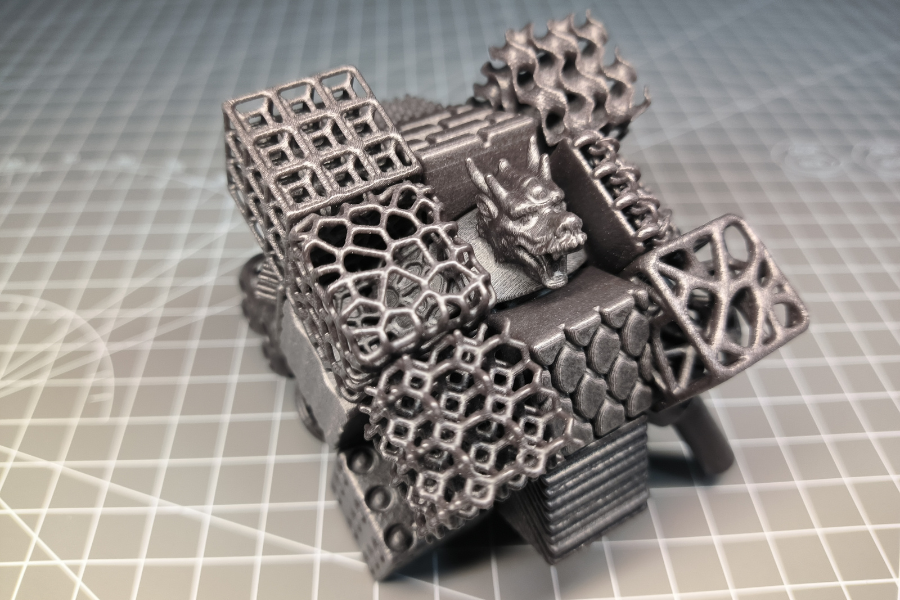

PP Pro is formulated for TPM3D SLS printing systems, enabling consistent polypropylene 3D printing for both prototypes and production runs. It maintains stable dimensional accuracy, repeatable performance, and high-quality surface finish in 3D printing polypropylene applications.