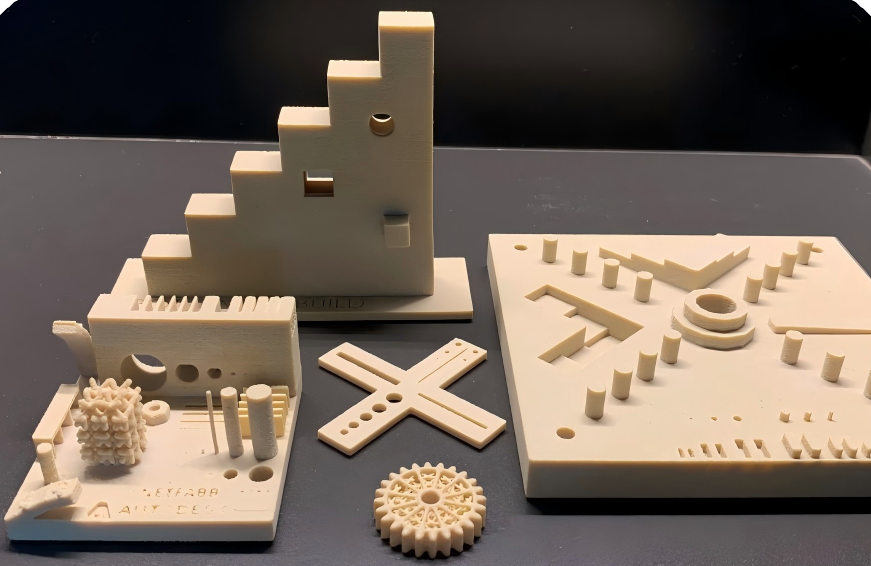

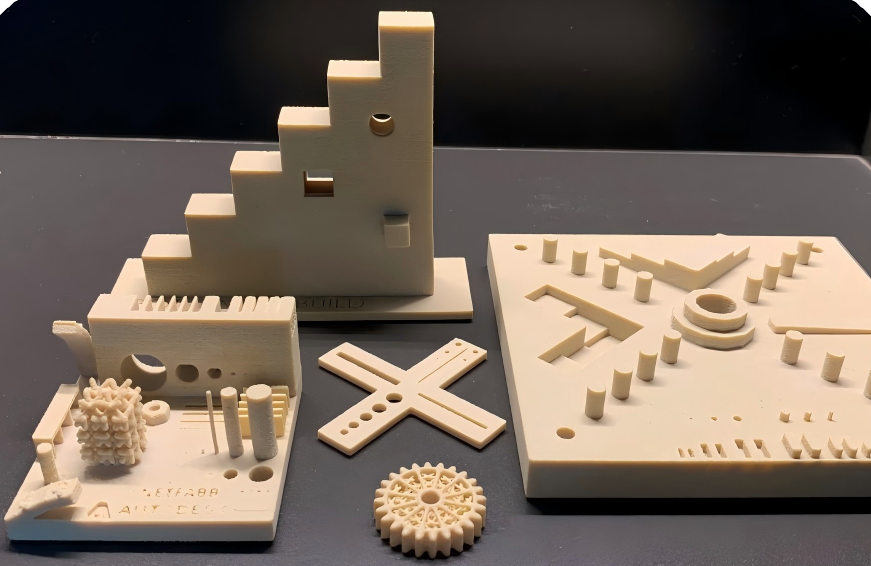

TPM3D PEKK IND is a high-performance SLS material made from polyetherketoneketone, offering high stiffness, flame retardancy, and chemical stability. Compatible with high-temperature 3D printing, it is designed for demanding applications in aerospace, mechanical engineering, and industrial sectors where high rigidity and thermal resistance are essential.

| Mechanical properties | Test method | Metric |

| Part Color | Visual | Yellowish Black |

| Elongation at break | ISO 527 | 2.3% |

| Tensile Strength (MPa) | ISO 527 | 81 Mpa |

| Tensile Modulus (MPa) | ISO 527 | 4,000 Mpa |

| Flexural Strength (MPa) | ISO 178 | 160 Mpa |

| Flexural Modulus (MPa) | ISO 178 | 7,200 MPa |

| Single Notch Impact Resistance (KJ/m2) | ISO 180 | 4.5 KJ/m2 |

| Double Notch Impact (KJ/m2) | ISO 180 | 3.969 KJ/m2 |

| Thermal Deformation Temperature (°C) | >200°C |

TPM3D PEKK IND delivers strength, stability, and safety for demanding industrial projects.

TPM3D PEKK IND is valued by manufacturers for its performance in high-stress and high-temperature conditions. It is particularly suited for:

TPM3D PEKK IND is designed to work with TPM3D’s S320HT high-temperature 3D printer. Whether producing single prototypes or full-scale production runs, the material supports PEKK 3D printing with stable mechanical performance, consistent surface quality, and reliable dimensional control.