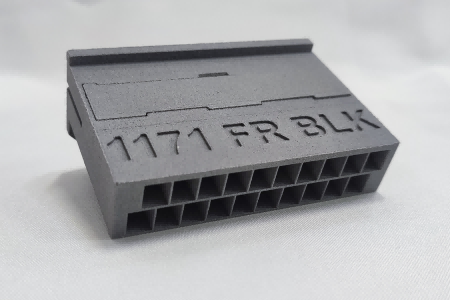

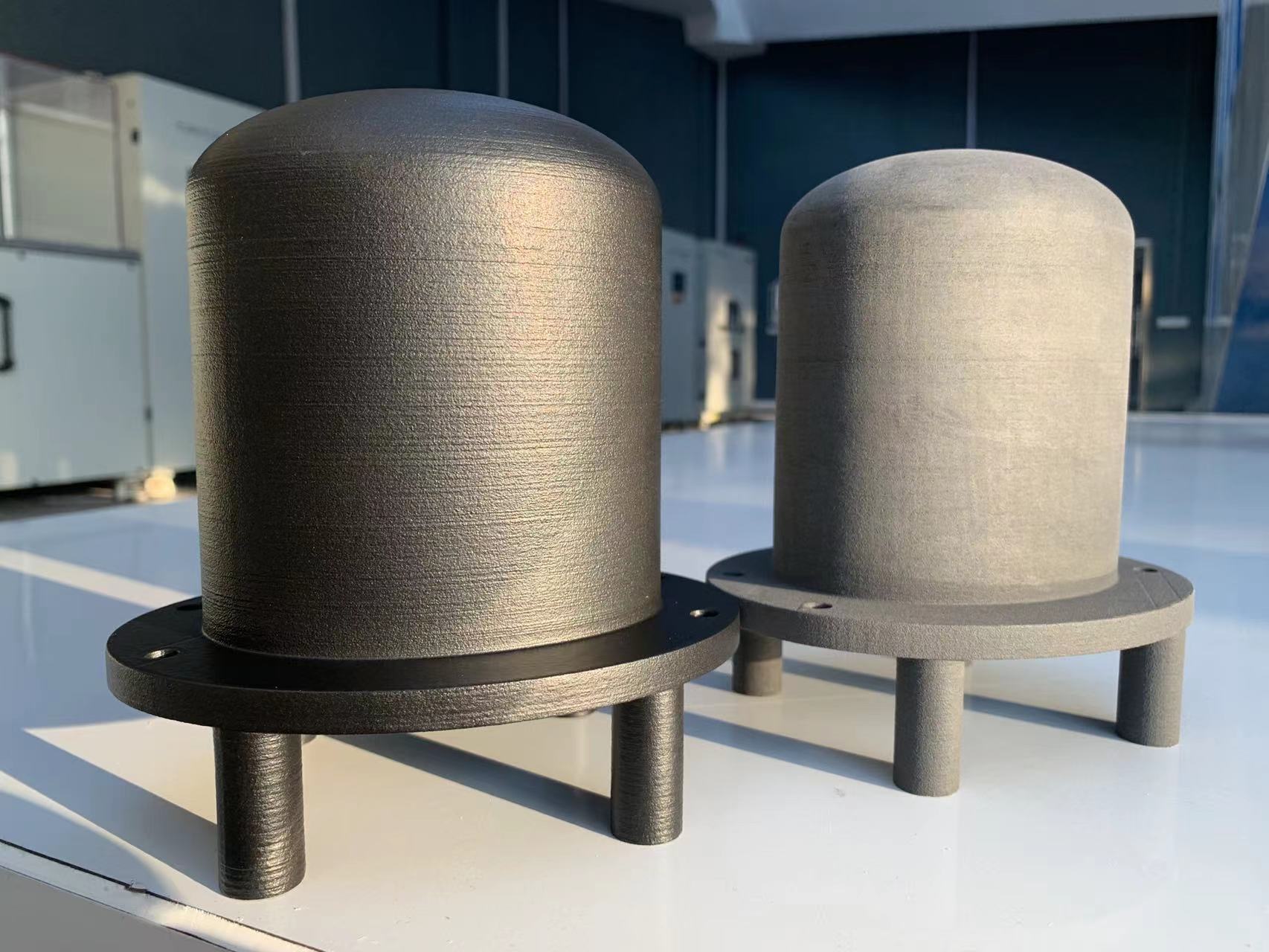

Precimid1174Pro CF | Carbon Fiber Reinforced Black Nylon 12 Powder

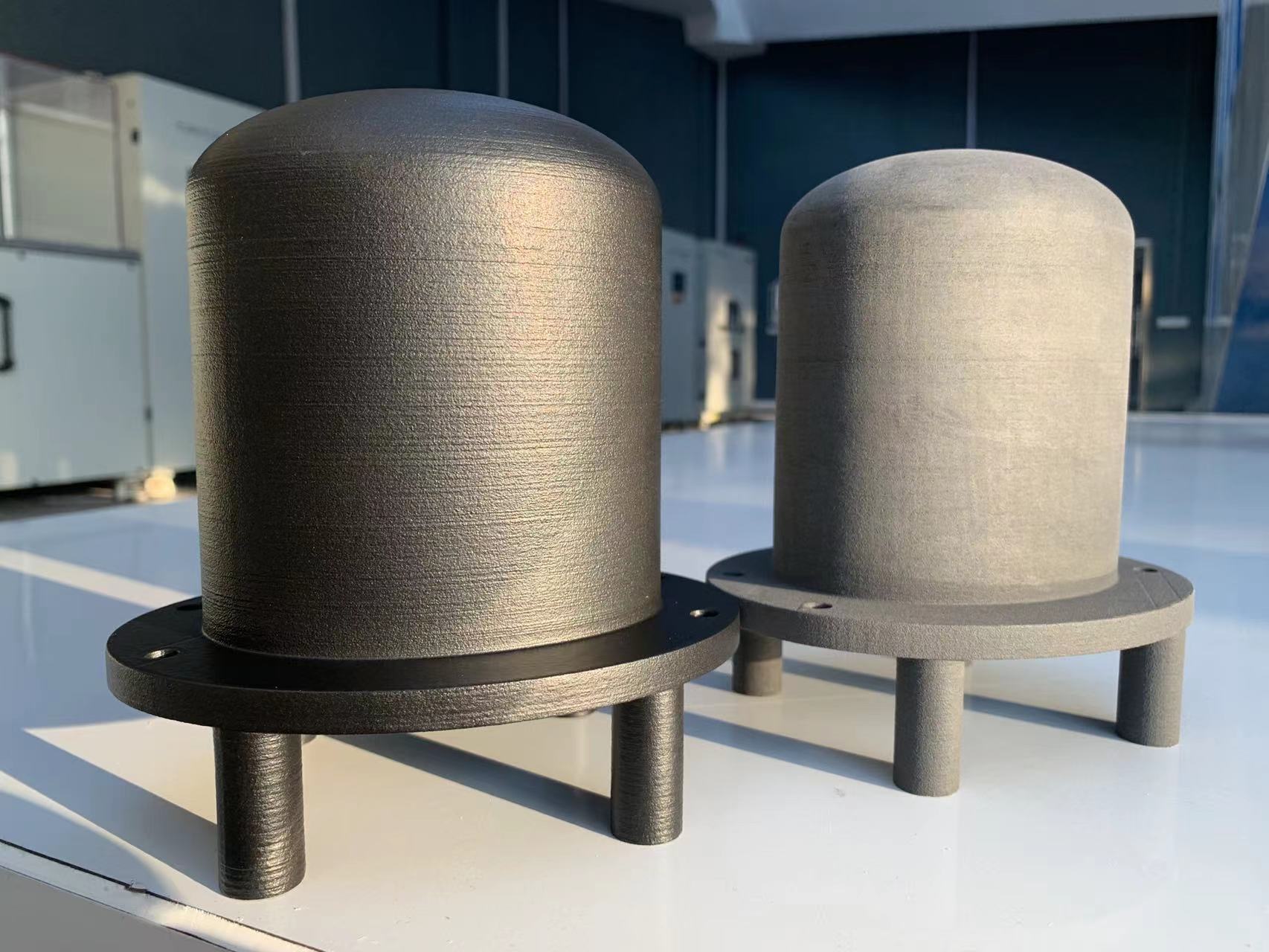

Precimid1174Pro CF is a carbon fiber reinforced nylon 12 powder offering high strength, hardness, and heat resistance, optimized for demanding applications like drones and high-rigidity parts.

- Carbon Fiber Reinforced: Contains 30% carbon fiber to enhance stiffness and mechanical strength.

- High Strength and Hardness: Provides reliable performance for demanding structural parts.

- Heat Resistant: Suitable for components used in elevated temperature and high-pressure environments.

- Wear Resistant: Maintains durability in abrasive and mechanical stress conditions.

- Lightweight: Combines strength with reduced weight for aerospace and automotive applications.

Get A Free Quote

Precimid1174Pro CF Specifications

| Mechanical properties | Test method | Metric | ||

| Part Color | Visual | Ash Black | ||

| Density | DIN 53466 | 1.09g/cm³ | ||

| Elongation at break | ASTM D638 | X | Y | Z |

| 8.0% | 9.5% | 1.7% | ||

| Flexural strength | ASTM D790 | X | Y | Z |

| 135 MPa | 100 MPa | 66 MPa | ||

| Flexural modulus | ASTM D790 | X | Y | Z |

| 6,000 MPa |

4,500 MPa |

3,000 MPa |

||

| Heart Deflection temperature 0.45MPa | ASTM D648 | 172 ℃ | ||

| Heart Deflection temperature 1.82MPa | ASTM D648 | 172 ℃ | ||

| Tensile strength | ASTM D638 | X | Y | Z |

| 88 MPa | 63 MPa | 36 MPa | ||

| Tensile modulus | ASTM D638 | X | Y | Z |

| 9,000 MPa | 6,400 MPa | 3,500 MPa | ||

| IZOD impact strength with notch | ASTM D256 | X | Y | Z |

| 35 J/M | 35 J/M | 22 J/M | ||

| IZOD impact strength without notch | ASTM D256 | X | Y | Z |

| 6.3 J/M | 6.8 J/M | 3.5 J/M | ||

| Specific Surface Resistivity | IEC 62631-3-2 | Typical Value (X-direction) |

Typical Value (Z-direction) |

|

| 5kΩ | 5kΩ | |||

Looking for high-strength carbon fiber reinforced nylon?

Choose Precimid1174Pro CF for rigid, heat-resistant 3D printed parts.

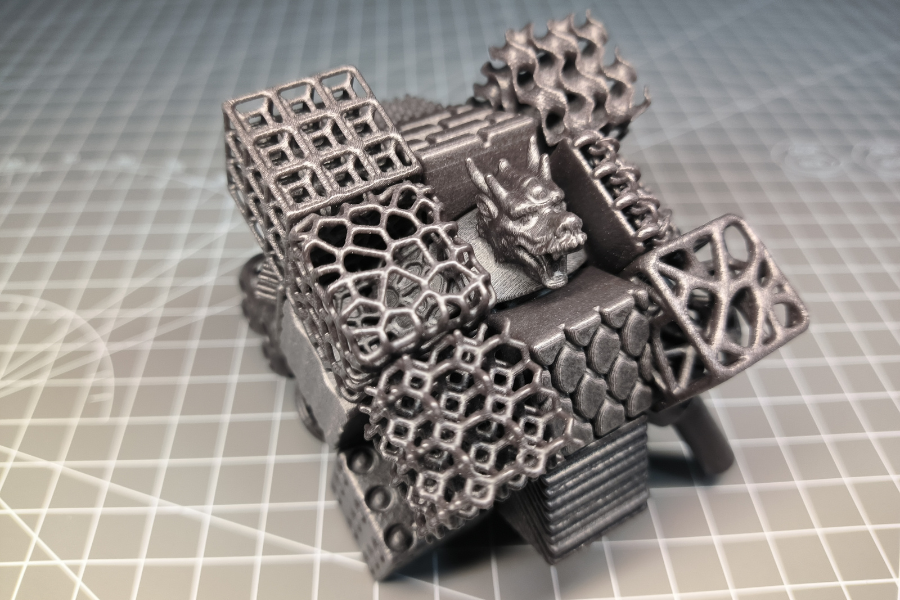

Precimid1174Pro CF Applications

Precimid1174Pro CF is designed for industries requiring strong, heat-resistant, and durable materials:

- Drones – Lightweight parts with excellent rigidity and durability.

- High Rigidity Components – Structural parts for demanding mechanical loads.

- Heat and Pressure Resistant Applications – Parts performing reliably under thermal and mechanical stress.

- Robotics – Components requiring toughness and wear resistance.

- Automotive – Suitable for parts exposed to heat and harsh conditions.

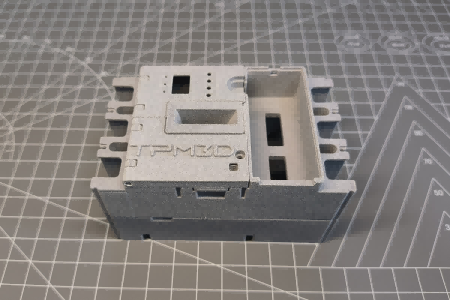

Seamless Compatibility with SLS 3D Printers

Precimid1174Pro CF is developed to work seamlessly with TPM3D’s SLS 3D printers, delivering consistent quality, accuracy, and surface finish for industrial-grade production.