Precimid1130 88A | Natural White TPU Material

Precimid1130 88A is a soft TPU powder for SLS printing, offering excellent shock absorption, flexibility, water resistance, and 80% reusability.

- High Flexibility (88–90 Shore A): Soft-touch feel with excellent elasticity for dynamic parts.

- Superior Impact & Shock Resistance: Absorbs shocks and resists deformation under repeated stress.

- Water, Heat, and Mold Resistant: Ideal for applications exposed to moisture and temperature variations.

- Excellent Recovery and Fatigue Resistance: Maintains shape and performance under repetitive loads.

- High Refresh Rate (40%): Supports sustainable production with low material waste.

Get A Free Quote

Precimid1130 88A Specifications

| Mechanical properties | Test Method | Typical Values X-Direction | Typical Values Z-Direction |

| Shore A Hardness | DIN ISO 7619-1 | 88-90 | 88-90 |

| Tensile Strength (MPa) | DIN 53504, S2 | 8 | 7 |

| Tensile Elongation at Break (%) | DIN 53504, S2 | 270 | 130 |

| Tensile Modulus (MPa) | ISO 527-2, 1A | 75 | 75 |

| Flexural Modulus (MPa) | DIN EN ISO 178 | 70 | 70 |

| Tear Resistance (propagation, Trouser) (kN/m) | DIN ISO 34-1, A | 26 | 26 |

| Tear Strength (initiation, Graves) (kN/m) | DIN ISO 34-1, B | 43 | 37 |

| Compression Set B (23°C, 72h) (%) | DIN ISO 815-1 | 24 | 24 |

| Rebound resilience (%) | DIN 53512 | 63 | 63 |

| Abrasion Resistance (mm³) | DIN ISO 4649 | 86 | 95 |

| Charpy lmpact Strength (notched, 23°C) / kJ/m² | DIN EN ISO 179-1 | No break | No break |

| Charpy lmpact Strength (notched, -10°C)\ / kJ/m² | DIN EN ISO 179-1 | 60 | 58 |

| Fatigue (Ross Flex, 100k cycles, 23°C) | ASTM D1052 | No crack | – |

| Fatigue (Ross Flex, 100k cycles, -10°C) | ASTM D1052 | No crack | – |

Need Flexible, Tough & Water-Resistant TPU?

Try 1130 88A for cushioning and shock resistance.

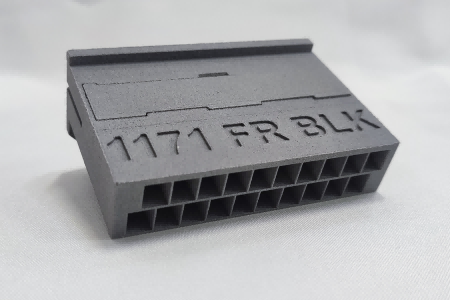

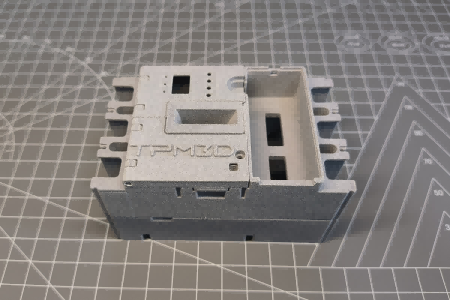

Seamless Compatibility with SLS 3D Printers

Precimid1130 88A is compatible with TPM3D’s full range of SLS systems, enabling consistent production of soft, high-durability components with reliable detail resolution.