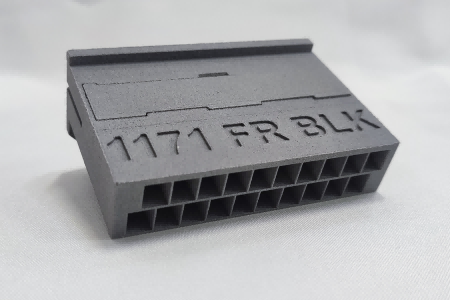

TPM3D PA6X BLK | Dark Grey Polyamide 613

TPM3D PA6X BLK is a polyamide 6 (PA 6) powder developed for Selective Laser Sintering (SLS) 3D printing. It combines high mechanical strength with lower moisture absorption, wear resistance, and excellent thermal and chemical stability. This makes it an ideal choice for applications operating in challenging environments, including those requiring resistance to oil, fuel, and solvents.

- High Mechanical Strength: Maintains reliable performance under mechanical stress.

- Low Moisture Absorption: Preserves dimensional stability in humid environments.

- Wear Resistance & Self-Lubrication: Reduces friction for longer component life.

- Chemical Resistance: Withstands exposure to oils, fuels, and a variety of solvents.

- Thermal Stability: Operates in elevated temperature conditions without loss of properties.

TPM3D PA6X BLK Specifications

| Mechanical properties | Test method | Metric |

| Part Color | Visual | Grey |

| Density | DIN 53466 | N/A kg/m³ |

| Elongation at break | ASTM D638 | 17.0% |

| Flexural strength | ASTM D790 | 75 MPa |

| Flexural modulus | ASTM D790 | 1,500 MPа |

| Heart Deflection temperature 0.45MPa | ASTM D648 | 190 °C |

| Heart Deflection temperature 1.82MPa | ASTM D648 | 70 °C |

| Tensile strength | ASTM D638 | 51 MPa |

| Tensile modulus | ASTM D638 | 2,000 MPa |

| IZOD impact strength with notch | ASTM D256 | 70 J/M² |

| IZOD impact strength without notch | ASTM D256 | 450 J/M² |

Why Choose TPM3D PA6X BLK?

TPM3D PA6X BLK offers the balance of strength, wear resistance, and thermal stability needed for long-lasting performance.

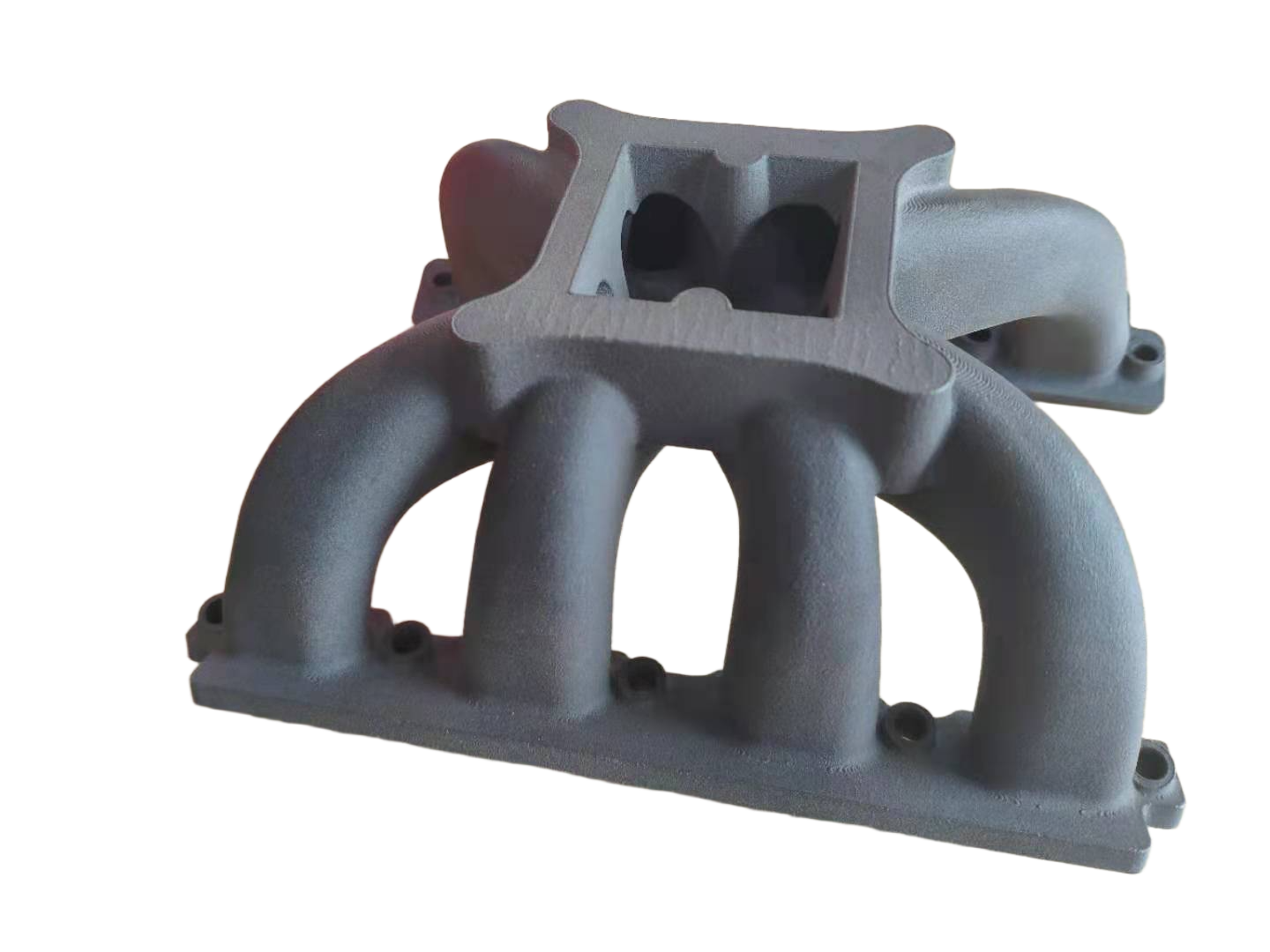

TPM3D PA6X BLK Applications

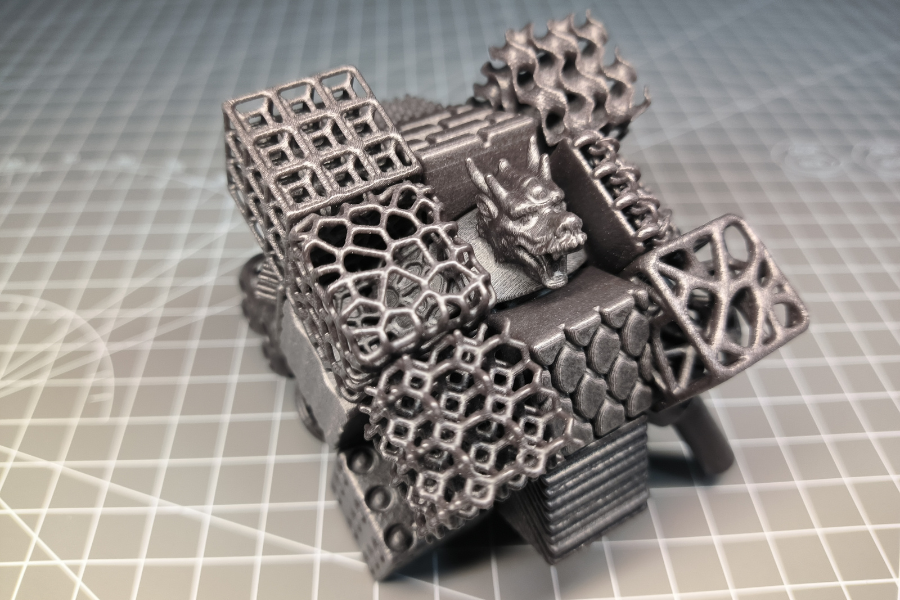

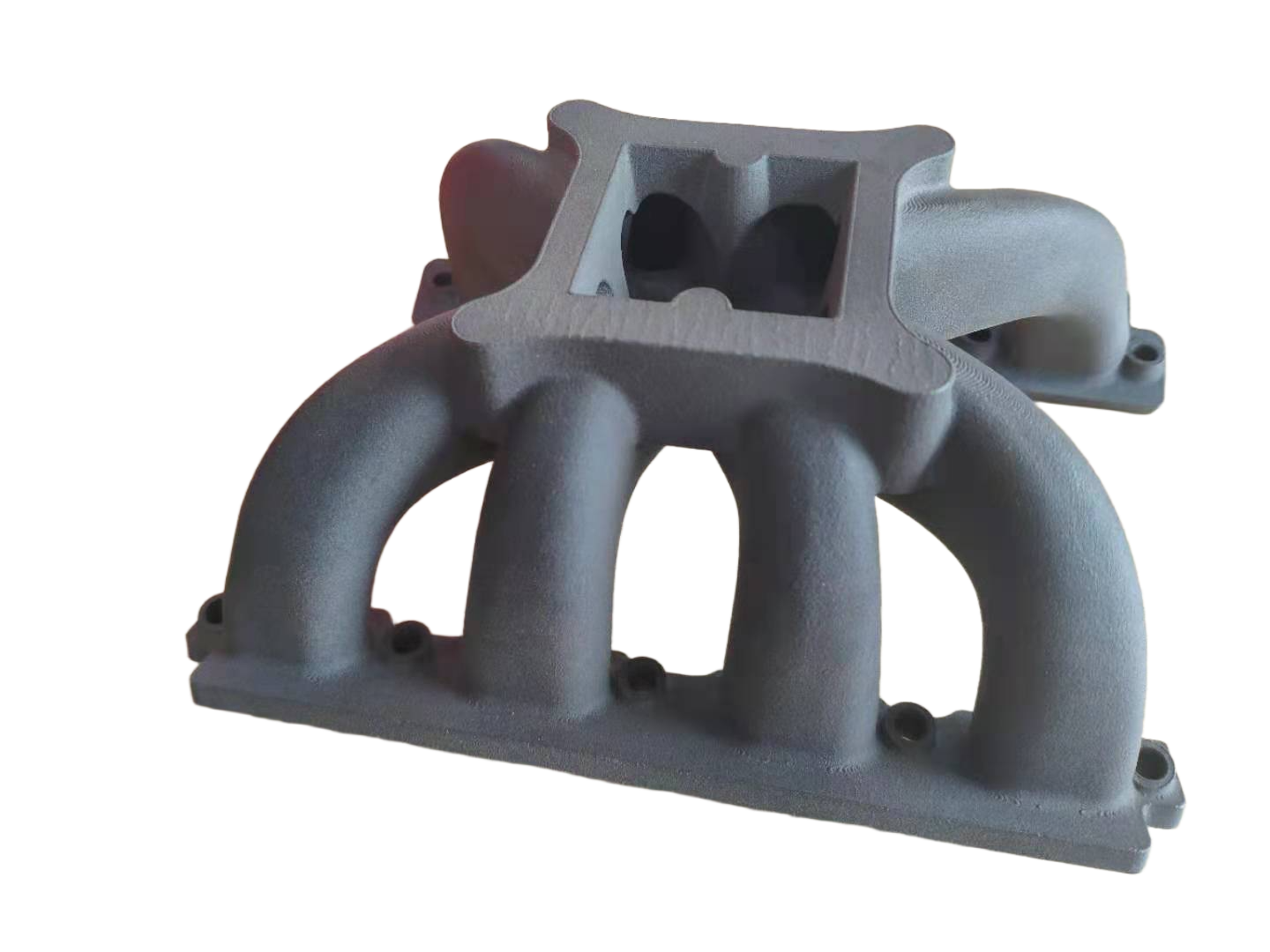

TPM3D PA6X BLK is engineered for complex, high-demand parts such as:

- High-Temperature Components

- Challenging Operating Environments

- Oil & Gas Applications

- Automotive Parts

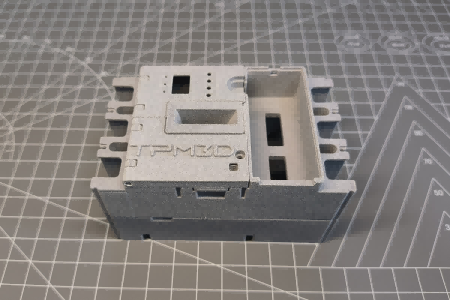

- Functional Shells & Complex Assemblies

Seamless Compatibility with SLS 3D Printers

TPM3D PA6X BLK is optimized for TPM3D SLS printing systems, delivering high-quality results whether producing prototypes or end-use parts, with excellent surface finish and dimensional accuracy.