Recently, TPM3D developed a flame-retardant nylon 12 material called Precimid1171 FR BLK. This material is specifically designed for industries such as electronics, automotive, and aerospace due to its excellent overall mechanical properties, heat resistance, wear resistance, and compliance with the UL94-2013 standard V-0 rating requirement after passing SGS's vertical combustion test.

So what are the applications of this material? Let's take a closer look:

Application in Electronics

Firstly, it can be used in the field of electronics. Low-voltage electrical appliances require high flame retardancy performance from their products. Therefore, using this flame-retardant nylon material can effectively improve product safety. Recently, TPM3D collaborated with a well-known electrical appliance manufacturer to conduct arc extinguishing tests on circuit breakers printed with Precimid1171 FR BLK. The results showed that when subjected to a current of 16,000A for 5 seconds and producing open flames and temperatures exceeding 1000℃, the material was able to quickly extinguish the fire. Most of the 3D printed structures were also blackened but did not deform significantly and could meet the requirements of arc extinguishing tests during trial production. In addition, compared to traditional outsourced processing circuit breakers, using SLS printing technology can reduce costs to around 700 yuan per set while saving 82.5%. Furthermore, parts can be obtained within 48 hours which saves time by up to 60%. This not only helps companies avoid high costs and long cycles caused by CNC machining and mold making but also effectively improves product quality.

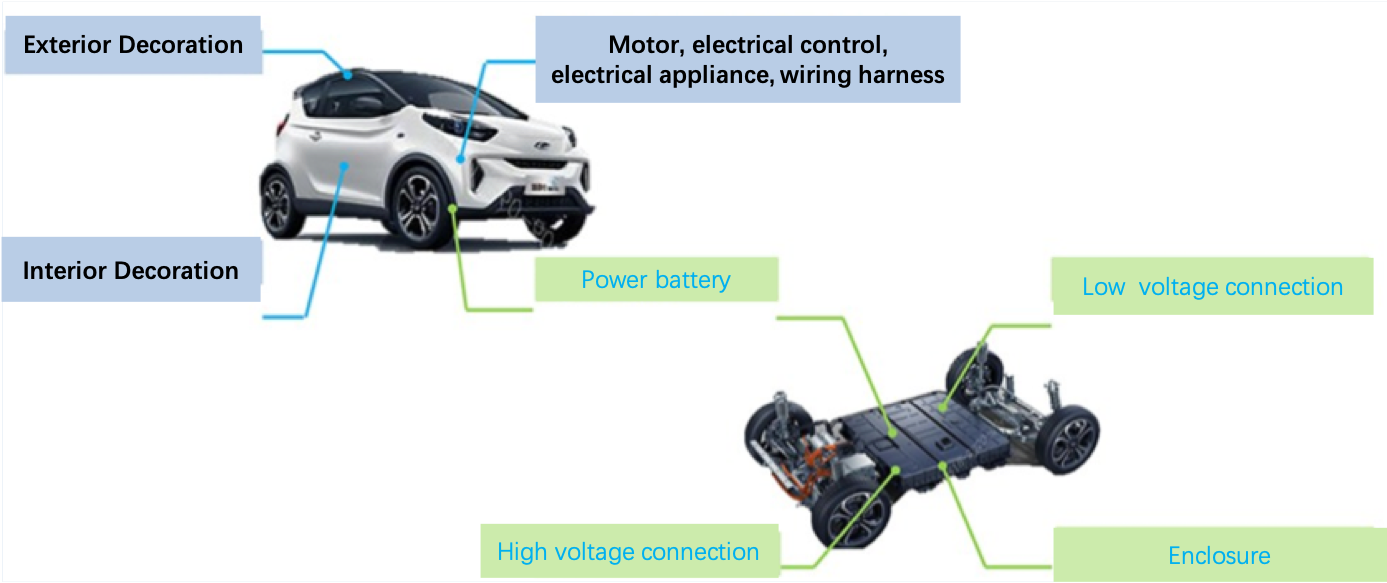

Application in New Energy Vehicles

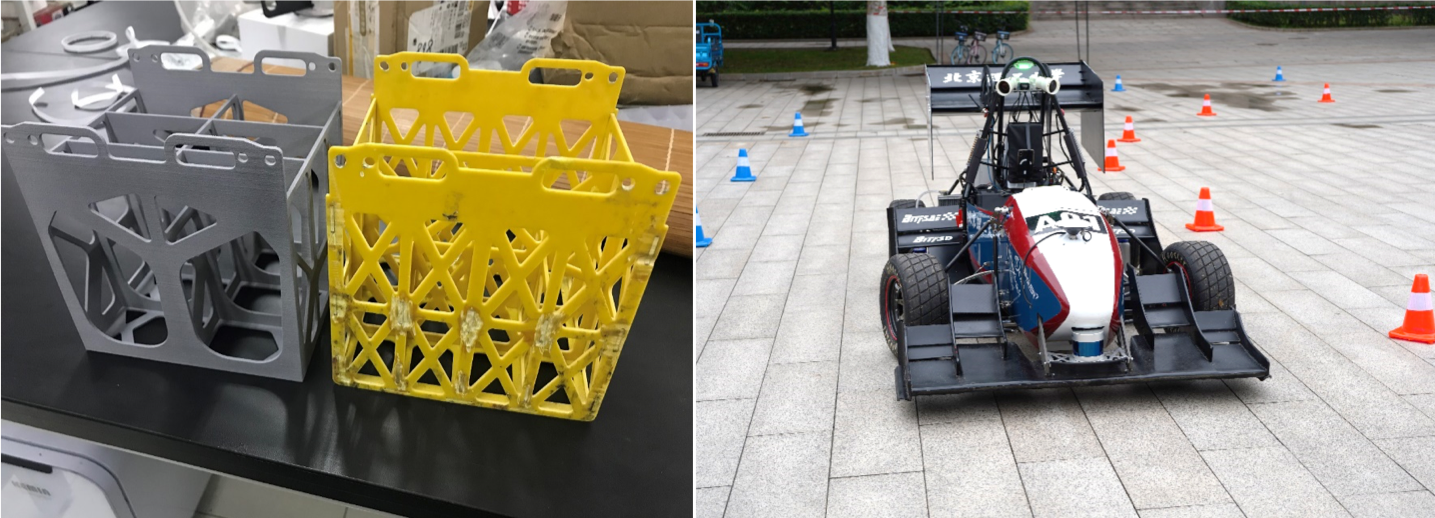

Secondly, it can be used in the field of new energy vehicles. With an increase in electric car fires in recent years, vehicle safety has become an important factor for consumers' consideration. Therefore, flame-retardant materials need to be applied in structures such as interior and exterior decorations, electrical control wiring harnesses, and power batteries. Especially for the power battery, which is the core of the vehicle's energy source, components such as the upper shell, explosion-proof valve, high-low voltage plug-ins, wiring harnesses, internal heating devices need to consider flame retardancy issues and have corresponding standards. Currently, TPM3D continues to sponsor Beijing Institute of Technology's unmanned racing team and Tongji University's electric racing team. Many race car parts printed for them include flame-retardant battery module frames made from Precimid1171 FR BLK material. These 3D printed battery module frames can act as a barrier and delay combustion spread when the battery core malfunctions and causes thermal runaway burning. This improves the safety factor of the race car while reducing weight and improving performance. Although 3D printing flame-retardant materials are still relatively new in the field of new energy vehicles and are quite basic at present, we believe that with continuous exploration and innovation in this field, there is still more potential waiting for us to discover.

In summary, Precimid1171 FR BLK material has excellent overall mechanical properties, heat resistance, wear resistance, and flame retardancy properties. It has broad application prospects in industries such as electronics, automotive manufacturing, aerospace engineering etc.. At the same time with continuous innovation in 3D printing technology today this flame-retardant nylon material will continue to expand its applications providing safer, more efficient and environmentally friendly solutions for various industries.