On May 26-28, TCT Asia 2021 took place at the National Exhibition and Convention Center (Shanghai), bringing together more than 200 domestic and foreign 3D printing enterprises. TPM3D 3D made an innovative debut at this year's event.

Highlight 1: Launch of new products has become focus of attention both online and offline

In response to the continuous expansion of the 3D printing application industry and the latest demands of customers in different industries, TPM3D, focusing on users’ feedback and industry application directions and persisting in innovation, has successfully developed small ultra-high temperature and large dual laser SLS printers. At the TCT Asia 2021, it teamed up with two major media of the industry, “Nanjixiong” and “Unlands”, to promote new products offline and online, analyzing their advantages and characteristics from the technical and market aspects and attracting nearly 1,800 industry experts online.

S150HT: with the shape-taking chamber temperature of 350℃, it can print high-temperature and high-performance materials such as PEEK into various sizes as required, and help customers accelerate the development and iterative test verification of new materials and new products while substantially reducing the costs.

S800DL: with the build chamber size of 800×800mm, it can not only improve the parts quality, but also improve the printign speed, thus easily completing the printing tasks of large parts.

P480DL: with the build size of 138,240cm³, it adopts the dual laser intelligent collaboration system. Compared with S480, which is warmly welcomed by automobile manufacturers, its printing efficiency is improved by up to 40%, meeting the pursuit of the users for ultimate production efficiency.

Highlight 2: Signing ceremony for the second purchase with Nanjing Superior

Since Nanjing Superior introduced TPM3D’s P series high-performance laser sintering nylon printing equipment in 2019, its business volume of manufacturing plastic parts by 3D printing has greatly increased. After the introduction of industrial capital in 2021, in order to quickly realize large-scale production, it planned to spend RMB 10 million to purchase ten new-generation industrial SLS polymer laser 3D printers from TPM3D. Both parties held a signing ceremony at the site of the TCT.

The printing system of TPM3D introduced by Nanjing Superior this time includes a group of two dual-laser printing systems, a P550 unit and a Parts & Power Processing Station (PPS), which will improve printing efficiency by 40% and save the materials by 15%. With a printing volume of 100,000 Hz, it is currently the largest carbon dioxide continuous laser 3D printing system in China.

Highlight 3:Technology seminar

During this event, TPM3D held an application seminar with Hangzhou SCANTECH (one of the world’s earliest high-tech enterprises that have developed and produced handheld 3D vision measurement products) to share the industry information of 3D printing and 3D digitization with the industry and explore the future market development trends and opportunities.

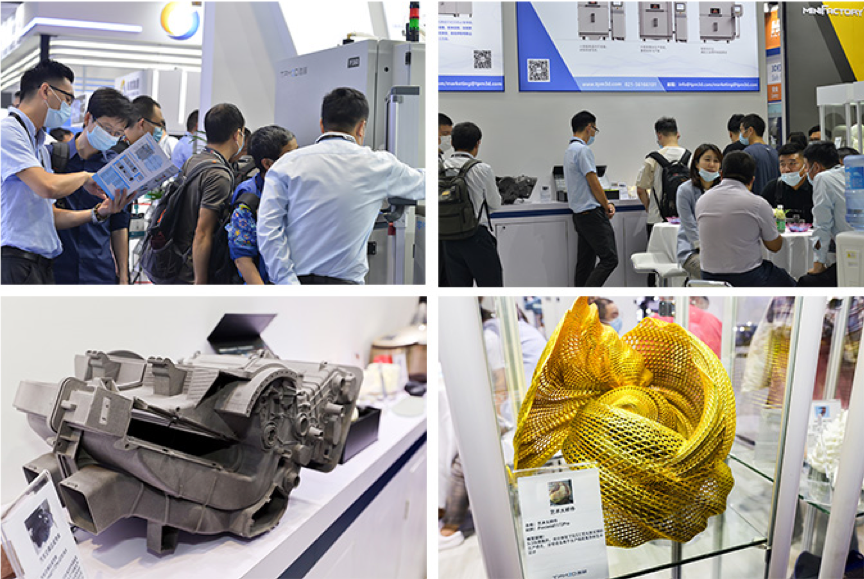

Highlight 4: Professional SLS equipment and exhibits attracting the audience to the booth of TPM3D

At TCT 2021, TPM3D exhibited its best-selling products, P360 high-performance printing equipment and PPS, as well as exquisite printing samples of different industries, which attracted the attention of the audience.

The P Series is a new generation of additive manufacturing system for Asian customer,, featuring high reliability, cost-effective and the printing speed comparable to that of the S series. The PPS is a clean production solution successfully launched by the team of TPM3D after years of research, integrate parts cleaning, powder recycling, feeding, mixing, and powder collecting. It effectively solves the problems in the manufacturing of laser sintering powder additives, thus making the parts post-processing much easier.